Why Temperature Makes or Breaks Your Delivery Game

Temperature is crucial for a positive food delivery experience. Think about it: lukewarm fries, congealed sauce, or a cold burger can instantly disappoint a customer. This not only affects their immediate satisfaction but can also damage your restaurant’s reputation and hurt future orders. A single negative online review mentioning cold food can be a major deterrent for potential customers. It shows how a few degrees can drastically shift perceptions of your restaurant. This directly translates to lost revenue and decreased brand loyalty. Knowing how to keep food warm for delivery is essential for long-term success.

The Science Behind Heat Retention

Knowing how to keep food warm for delivery relies on understanding basic thermodynamics. Heat naturally travels from hotter objects to cooler ones. This means your freshly prepared meal will inevitably lose heat to its surroundings during transit.

The goal is to slow this heat loss as much as possible. Insulation acts as a barrier, reducing the rate of heat transfer and preserving warmth. A thermos, for instance, utilizes a vacuum to minimize this heat exchange, keeping coffee hot for hours. This same principle applies to food delivery containers.

Meeting Safety and Legal Requirements

Beyond customer satisfaction, maintaining correct food temperatures is paramount for food safety. Regulations specify temperature ranges for hot foods to prevent bacterial growth and safeguard consumer health. Ignoring these guidelines can lead to serious health risks and legal consequences.

This makes temperature control not simply a matter of good service, but a legal requirement. Investing in reliable warming equipment and monitoring procedures protects both your customers and your business.

The online food delivery market is booming. In the United States alone, it’s expected to leap from $31.11 billion in 2024 to $72.94 billion by 2033, fueled by the convenience of services like Uber Eats, DoorDash, and Grubhub. These platforms often utilize insulated containers and optimized delivery routes to maintain food temperature.

This market growth emphasizes the increasing importance of temperature control in meeting the expectations of a growing customer base. Maintaining high food quality is key to standing out.

Insulation Solutions That Actually Keep Food Hot

Forget flimsy foil and those basic delivery bags. If you’re serious about delivering top-notch food, you need to think strategically about insulation. The materials and methods you choose have a direct impact on the food quality your customers experience. This isn’t just about maintaining flavor; it’s about building a reputation for excellence and ensuring those all-important repeat orders.

Understanding Insulation Materials

Different insulation materials offer varying degrees of heat retention. Expanded polystyrene (EPS) foam, commonly known as Styrofoam, is a budget-friendly option. However, it’s not the most durable, and its environmental impact is a growing concern. Polypropylene, often used in reusable containers, provides decent insulation and is easy to clean.

For premium insulation, consider Neoprene or thick, padded nylon, which are often found in high-end delivery bags. These materials create a thermal barrier, trapping heat and preventing it from escaping. Think of it like a winter coat for your food, shielding it from the cold outside world.

Layering for Optimal Heat Retention

Simply using an insulated bag isn’t always enough. Layering different insulation materials can significantly improve heat retention. For instance, lining an insulated bag with a reflective material like aluminum foil can further reduce heat loss by reflecting radiant heat back towards the food.

Additionally, strategically using air gaps creates additional insulation. This can be achieved by wrapping individual containers in an insulating material before placing them inside the delivery bag.

Preheating Containers: A Simple Yet Effective Strategy

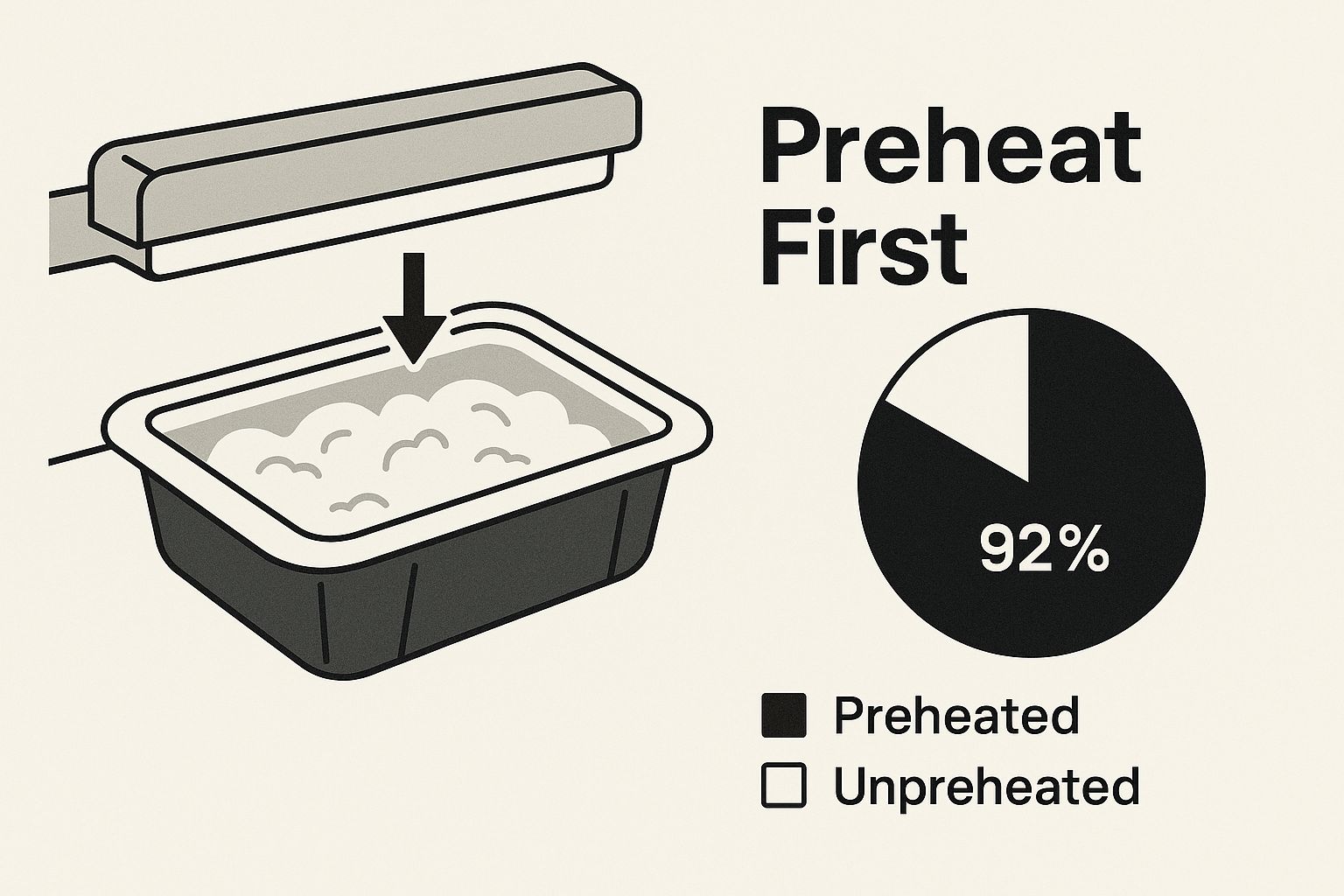

Preheating your delivery containers before adding hot food can dramatically impact temperature maintenance during transit. Just as a preheated oven maintains a consistent temperature for baking, a preheated container minimizes the initial temperature drop when hot food is added. This helps the food stay warmer for a significantly longer period.

This infographic illustrates how preheating affects temperature retention. This simple step goes a long way in extending the time your food remains at the perfect serving temperature.

The Growing Importance of Temperature Control

The global demand for efficient food delivery is booming, driven by consumers’ desire for convenience. The global online food delivery market is projected to hit $1.39 trillion by 2025, growing at a CAGR of 7.64% from 2025 to 2030. Keeping food warm is crucial for customer satisfaction and directly affects how customers perceive the quality of their meal.

This growth means that investing in effective insulation isn’t just a smart move; it’s essential for competing in this expanding market. By understanding how heat retention works and using practical insulation strategies, you can ensure your food arrives piping hot and ready to be enjoyed.

To help illustrate the different insulation options available, take a look at the comparison table below:

Insulation Solutions Comparison Guide

| Insulation Type | Heat Retention Time | Cost Range | Best For | Pros | Cons |

|---|---|---|---|---|---|

| Expanded Polystyrene (EPS) Foam | Short to Medium | Low | Short-distance deliveries, budget-conscious businesses | Cost-effective, readily available | Low durability, environmental concerns |

| Polypropylene | Medium | Moderate | Reusable containers, moderately priced meals | Durable, washable | Lower heat retention than premium options |

| Neoprene | High | High | Long-distance deliveries, premium meals | Excellent insulation, durable | Higher cost |

| Padded Nylon | High | High | Long-distance deliveries, premium meals | Excellent insulation, often water-resistant | Higher cost |

| Aluminum Foil Lining | Increases retention of other methods | Low | Supplementing other insulation | Improves heat reflection, cost-effective | Not effective on its own |

| Air Gaps | Increases retention of other methods | Low | Supplementing other insulation | Improves insulation, simple to implement | Requires extra packaging |

This table summarizes the key features of common insulation materials, helping you choose the best option for your needs. As you can see, balancing cost, heat retention, and sustainability is crucial for finding the ideal insulation solution for your food delivery business.

Smart Packaging Strategies for Maximum Heat Retention

Your packaging choices are essential for maintaining the temperature of delivered food. Even with a high-quality insulated delivery bag, the right containers and sealing methods can make all the difference. Successful restaurants understand this and use specific tactics to ensure their dishes arrive piping hot. This creates a positive customer experience and builds loyalty.

Container Selection: Matching Materials to Your Menu

Different foods have different packaging needs. Soups and sauces require leak-proof containers with secure lids. Fried foods, on the other hand, benefit from vented containers to prevent them from getting soggy. The container material is also crucial for heat retention. Polypropylene is a popular choice due to its versatility and durability. Aluminum offers excellent heat retention and works well for items like roasted vegetables or grilled meats.

Sealing Techniques: Locking in Heat, Keeping Out Condensation

Proper sealing prevents heat loss and maintains food quality during delivery. However, a completely airtight seal can trap moisture, leading to soggy food. Vented lids offer a solution for foods that tend to steam, like fried items. Tamper-evident seals provide an additional benefit. They not only maintain temperature but also reassure customers of food safety and integrity.

Layering for Maximum Impact: Eliminating Air Gaps and Maximizing Insulation

Strategic layering creates an effective thermal barrier, much like double-paned windows in a house. Wrapping individual containers in an insulating layer like aluminum foil or waxed paper before placing them in the delivery bag minimizes air gaps. This reduces heat loss and keeps food warmer for longer. The delivery bag acts as the final layer of insulation, protecting the food inside.

Adapting to the Elements: Weather and Distance Considerations

Weather and delivery distance are important factors to consider when choosing your packaging strategy. In colder climates or for longer deliveries, extra insulation or heat-retaining inserts can help maintain temperature. For shorter deliveries in warmer weather, breathable packaging may be necessary to prevent overheating. This flexible approach ensures consistent temperature control in any circumstance.

Route Planning That Protects Food Temperature

Time is the enemy of hot food. Every minute a meal spends in transit, it loses precious heat. But route planning can turn time into an advantage. Successful delivery operations don’t just use basic GPS; they optimize routes to minimize delivery time and maximize food quality. This careful approach is crucial for maintaining the correct temperature and ensuring happy customers.

Batching and Timing Strategies

Batching orders is key to efficient delivery. Grouping deliveries by location minimizes travel time and helps keep food warmer. It’s like a well-planned mail route, hitting multiple houses in one neighborhood before moving on. This is much better than a chaotic approach where every delivery is a separate trip.

Timing is also critical. Coordinating order preparation with driver arrival keeps food from sitting around. For example, if a driver is five minutes away, that’s the perfect time to finalize and package the meal. This synchronized approach maintains optimal food temperature.

Optimizing Multi-Stop Deliveries

Multiple deliveries add complexity. The challenge is maintaining the temperature for all orders. Strategies like separate insulated compartments are vital. This prevents temperature cross-contamination, ensuring each meal stays at its intended heat.

Delivering temperature-sensitive items first is also crucial. This minimizes their exposure to heat loss and helps ensure even delicate dishes arrive in great condition. The global food delivery industry is booming, projected to grow from $156.75 billion in 2024 to $173.57 billion in 2025, a 10.7% increase. This growth highlights the growing importance of temperature control in delivery.

Utilizing Technology and Backup Plans

Modern technology provides invaluable tools for route optimization. Real-time traffic updates and dynamic routing software like Waze help drivers avoid congestion and find the fastest routes. These tools enable on-the-fly adjustments, minimizing delays and preserving food temperature.

Even with the best planning, unexpected delays occur. That’s why backup plans are essential. Alternative routes or designated holding areas with warming equipment ensure food stays hot, even during unforeseen circumstances. This proactive approach protects food quality and keeps customers satisfied.

Advanced Heating Technology That Works

Keeping food warm during delivery is a constant challenge. Beyond traditional insulated bags, technology offers a range of exciting heating solutions. This article separates the true game-changers from the overpriced gadgets, helping you make informed decisions for your business. We’ll analyze portable heaters, battery-powered systems, and smart containers, assessing their return on investment (ROI) for various operation sizes. We’ll also delve into crucial safety considerations, power needs, realistic battery life expectations, and cost-benefit analyses from restaurants already using these technologies.

Portable Heating Solutions

Portable heating solutions offer on-the-go warmth, maintaining food temperatures throughout transit. Options range from simple heated bags to more sophisticated systems. Heated delivery bags utilize low-voltage heating elements to provide consistent warmth. Another option involves placing battery-powered heating pads inside insulated containers. However, factors like battery life and maintaining consistent heat output are key considerations.

Battery-Powered Systems: Power and Portability

When access to external power is limited, battery-powered heating systems offer much-needed portability. These systems typically involve insulated containers equipped with rechargeable battery packs that power heating elements. Battery life is a critical factor. Make sure your batteries can last the duration of your longest delivery routes, factoring in potential delays. Recharge time is equally important. Having sufficient backup batteries is essential to avoid workflow disruptions.

Smart Containers: The Future of Food Delivery?

Smart containers represent the latest advancements in food warming technology. These containers often integrate features like temperature sensors, built-in heating elements, and even GPS tracking. Some advanced systems offer remote temperature control and provide real-time feedback on food temperature throughout the delivery process. However, these advanced features often come at a premium price. Carefully assess whether the added benefits justify the higher cost for your particular operation.

To help you understand the landscape of available heating options, we’ve compiled the following table:

Heating Technology Options and Performance

| Technology Type | Power Source | Temperature Range | Battery Life | Initial Cost | Effectiveness Rating |

|---|---|---|---|---|---|

| Heated Delivery Bags | Low-voltage AC or DC | Adjustable, typically up to 160°F | N/A if AC powered | $50-$200 | Moderate |

| Battery-Powered Heating Pads | Rechargeable Battery | Limited, typically up to 140°F | 2-4 hours | $20-$50 per pad | Moderate |

| Smart Containers | Rechargeable Battery | Adjustable, typically up to 180°F | 4-6 hours | $100-$300 per container | High |

This table provides a general overview. Specific product features and performance can vary. Always thoroughly research individual products before investing.

Implementing Technology Upgrades Smoothly

Integrating new technology shouldn’t disrupt your existing workflow. Begin with a pilot program, testing the selected technology with a small group of drivers or on particular routes. Gather feedback from both drivers and customers to identify any operational issues and refine processes before a full-scale rollout. Thorough training for your staff on the proper use and maintenance of new equipment is crucial for optimal performance and maximizing your investment.

Taking a measured and strategic approach ensures the successful implementation of advanced heating technology to elevate your food delivery service. These investments can not only help keep food warm for delivery but also provide a competitive edge in the growing food delivery market.

Food-Specific Warming Techniques That Deliver Results

Maintaining the perfect temperature for delivered food is a nuanced art. It’s not a one-size-fits-all approach. Different foods demand different strategies. Your delivery plan needs to consider this, ensuring every dish, from a crispy pizza to a steaming bowl of soup, arrives in excellent condition. This focus on detail distinguishes ordinary deliveries from truly exceptional ones.

Conquering the Challenges of Mixed Orders

Mixed orders present a particular hurdle: maintaining both hot and cold temperatures within the same delivery. Imagine a fresh salad alongside a hot pasta dish. These contrasting temperatures require careful consideration. Separate insulated compartments within your delivery bag are essential. This prevents temperature cross-contamination, keeping the salad crisp and the pasta piping hot. It’s like creating individual microclimates within your delivery bag, each perfectly suited to the specific temperature requirements of the dish.

Timing Is Everything: Mastering Complex Meals

Timing is crucial, particularly with multi-component meals. Think of a meal featuring steak, roasted vegetables, and mashed potatoes. Each item has its own ideal holding temperature and cooking time. Staggering the cooking process ensures everything finishes simultaneously, minimizing wait times for any one component. This careful coordination keeps the entire meal at its optimal temperature upon arrival.

Special Attention Foods: Handling Delicate Dishes

Some foods require extra attention. Fried foods, like French fries or onion rings, are especially susceptible to sogginess. Using vented containers allows steam to escape, preserving that desirable crispness. Soups and sauces need leak-proof containers with secure lids to prevent spills. Pasta dishes benefit from a bit of extra sauce to retain moisture and prevent sticking. Understanding these nuances allows you to tailor your approach for a flawless culinary experience.

Troubleshooting Common Temperature Problems

Even the best-laid plans can sometimes encounter temperature-related hiccups. If fried foods arrive soggy, consider increasing container ventilation. For lukewarm soups, preheating the containers can be beneficial. Dry pasta dishes can be easily remedied by adding a touch of extra sauce during preparation.

Adapting to Cuisines and Seasonal Changes

Different cuisines and seasonal menus present unique temperature challenges. Spicy dishes often retain heat better than lighter fare. During summer months, preventing cold items from overheating becomes just as important as keeping hot food warm. Adapting your insulation and packaging to these factors ensures optimal temperature control throughout the year.

By understanding the specific warming needs of different foods, you can significantly improve your delivery service and consistently create a positive customer experience. This attention to detail demonstrates a commitment to quality, fosters customer loyalty, and sets your business apart.

Measuring Success and Continuous Improvement

Maintaining optimal food temperature during delivery is a continuous process, not a one-time fix. Shifting from guesswork to a data-driven system offers a real competitive edge. This means consistently monitoring performance, gathering customer feedback, and making improvements that deliver tangible results. This constant cycle of improvement helps ensure you’re always adapting and refining your processes for maximum effectiveness.

Temperature Monitoring: Tools and Techniques

Temperature monitoring is essential for effective temperature management. Affordable tools, like digital thermometers and temperature data loggers, offer valuable insights into temperature fluctuations during delivery. These tools can help pinpoint weaknesses in your system, allowing you to focus on areas for improvement. For instance, if data consistently reveals a significant temperature drop during a particular part of your delivery route, you can explore solutions like adjusting the route or adding more insulation.

Establishing Quality Benchmarks: Meeting Customer Expectations

Understanding customer expectations is crucial. Setting clear quality benchmarks helps align your operations with what matters most to your customers. These benchmarks could include target delivery times, acceptable temperature ranges on arrival, and specific food quality criteria, such as crispness for fried foods. For example, a benchmark could be that all hot food arrives at a minimum temperature of 140°F.

Customer Feedback: The Key to Continuous Improvement

Customer feedback is invaluable for refining temperature management strategies. Implement systems for collecting feedback, such as online surveys, comment cards, or simply asking customers directly. Actively seeking and analyzing feedback helps you understand customer perceptions of your food quality and identify areas for improvement. This insight is essential for making informed decisions about process adjustments.

Implementing and Evaluating Improvements: Closing the Loop

After gathering data and feedback, implement targeted improvements. This might involve adjusting packaging, refining delivery routes, or retraining staff on proper handling procedures. Regular temperature audits, systematically testing different parts of your delivery process, help evaluate the effectiveness of these changes. This creates a feedback loop that drives continuous improvement, ensuring customers consistently receive perfectly warmed food.

Investing in high-quality takeout packaging and delivery supplies is critical for maintaining temperature. MrTakeOutBags.com offers a wide selection of products and expert advice to optimize your food delivery process. From insulated bags to tamper-evident containers, they provide everything needed to deliver a superior customer experience.

Comments are closed.