Understanding The Frozen Food Shipping Revolution

The frozen food delivery scene has totally transformed. If your shipping methods haven’t kept up, you’re probably losing money and product. I’ve witnessed this change firsthand, helping businesses ranging from small ice cream shops to huge meal delivery companies navigate this new terrain. The explosion in frozen food’s popularity has created a whole new set of shipping hurdles.

This isn’t about stocking your freezer with TV dinners anymore. The market’s demands have become much more complex, requiring faster and more dependable shipping. Think gourmet frozen meals, pints of organic ice cream arriving on doorsteps, and even boxes of flash-frozen produce. These products need a sophisticated cold chain—a system that maintains specific temperatures from the warehouse all the way to the customer’s home. Old-school methods just won’t work.

This massive market growth has a huge impact on your shipping choices. Understanding the current landscape is essential for making informed decisions that will protect both your product and your bottom line.

The Numbers Tell the Story

The global frozen food market is experiencing remarkable growth. In 2023, it was valued at $284.2 billion, and projections show it reaching $363.7 billion by 2028, a 5.1% annual growth rate. This expansion is driving the need for more advanced and dependable shipping methods. These advancements in cold chain logistics are reshaping how frozen food is delivered and opening up exciting opportunities for businesses of every size. By understanding and adapting to these changes, you can really optimize your shipping and gain a competitive advantage.

Matching Shipping Methods To Your 2025 Specific Products

The biggest mistake I see with frozen food shipping? People treat all frozen food the same. After rescuing countless businesses from shipping meltdowns, trust me, shipping premium gelato is nothing like shipping frozen salmon or pre-made meals. Every frozen product has its own temperature tolerance and vulnerability during transit. These little details can mean the difference between a happy customer and a soggy disaster.

Think about it: shipping a delicate pastry versus a bag of frozen peas. The pastry, super sensitive to temperature swings, needs precise climate control. Frozen veggies? A little more wiggle room. Picking the right shipping method comes down to understanding these nuances.

Distribution channels add another wrinkle. Supermarkets, convenience stores, specialty shops, and online platforms each have unique requirements. They demand specific shipping strategies to ensure freshness and safety on arrival. Ready-to-eat meals, seafood, and baked goods, for instance, all have very specific temperature needs in transit. This means adapting your methods across the entire supply chain.

Savvy businesses are evolving. They’re building adaptable warehousing and shipping strategies to manage these product variations. It’s not just about keeping things cold; it’s about knowing how cold and for how long each product needs. This targeted approach is key to smoothing out your shipping process and avoiding costly failures.

Mastering Packaging That Actually Protects Your Investment

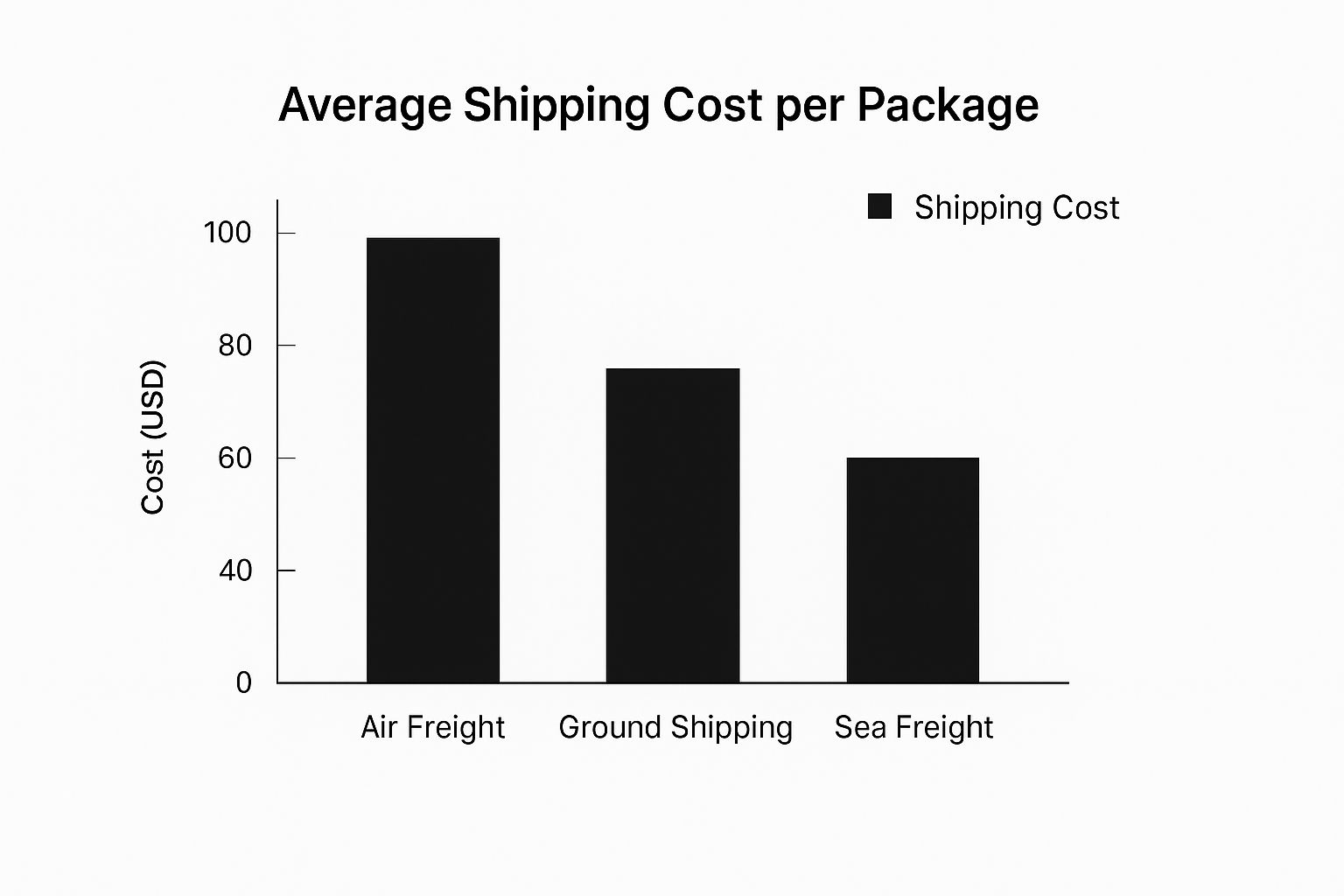

This infographic gives you a quick snapshot of average shipping costs – air, ground, and sea – for frozen goods. Air freight is definitely the speediest but comes with a hefty price tag. Sea freight is the most budget-friendly, but the extended travel time isn’t ideal for everything. The key takeaway? Balancing speed and cost is crucial when shipping frozen food.

I’ve seen firsthand how neglecting proper packaging can backfire. A friend of mine, who owns a small gourmet food business, once lost a huge shipment of premium steaks. Thousands of dollars down the drain, all because they tried to cut corners on insulation. Lesson learned: Solid packaging is non-negotiable. It’s your product’s first line of defense against temperature swings and potential damage during transit.

Choosing the Right Materials

So, what makes up a truly protective packaging system? Let’s break it down:

- Dry ice: The old standby. Great for maintaining those freezing temps, but requires careful handling.

- Gel packs: A reliable alternative, offering consistent temperature control.

- Phase Change Materials (PCMs): A newer technology that provides even more precise temperature regulation, particularly beneficial for highly temperature-sensitive products.

Beyond the cooling agents, box sizing is another critical factor. A snug fit prevents your products from shifting around and experiencing temperature variations. Too much space in the box can sabotage your efforts to maintain a consistent temperature.

Leak prevention is also paramount, especially for foods that could thaw and leak during shipping. Think waterproof liners and absorbent materials to contain any potential messes.

To help you navigate the different options, I’ve put together a comparison table:

Frozen Food Packaging Solutions Comparison

| Packaging Type | Temperature Hold Time | Cost Range | Best For | Pros/Cons |

|---|---|---|---|---|

| Dry Ice | 24-72 hours (depending on quantity and packaging) | Moderate to High | Meat, Seafood, Ice Cream | Pros: Effective for freezing; Cons: Requires special handling, can sublimate |

| Gel Packs | 12-48 hours (depending on size and quantity) | Low to Moderate | Prepared Meals, Desserts, Pharmaceuticals | Pros: Easy to handle, reusable; Cons: Shorter hold time than dry ice |

| PCMs | 24-96+ hours (depending on formulation and packaging) | Moderate to High | Pharmaceuticals, high-value frozen foods | Pros: Precise temperature control, longer hold times; Cons: Can be more expensive than other options |

| Insulated Liners/Boxes with Refrigerants | Varies greatly based on materials and refrigerants | Low to High | Wide range of frozen foods | Pros: Customizable insulation levels; Cons: Performance depends heavily on chosen materials and refrigerants |

This table summarizes the key characteristics of each option to help you choose the best fit for your product.

Finding the perfect packaging strategy is a balancing act between protection and cost. Overdoing it can inflate your shipping expenses, but skimping on protection risks losing your product altogether. Consider your product’s unique needs, the shipping distance, and your budget to find that sweet spot.

Choosing Carriers That Won’t Let You Down

Picking the right carrier for your frozen food is like choosing the right hiking boots. Bad boots, bad hike. Bad carrier? Melted messes. Every shipping company, from giants like FedEx and UPS to smaller niche frozen freight companies, has its own personality. And trust me, the customer service folks aren’t always transparent about the downsides.

I’ve personally witnessed the good, the bad, and the ugly of frozen food shipping. Some carriers have amazing temperature-controlled trucks, while others… let’s just say they’re less impressive. This isn’t just about getting a package across the country; it’s about maintaining that perfect temperature from door to door. Understanding these nuances is key.

What Happens Behind the Scenes?

The real question is what happens in transit? Do those fancy temperature monitoring systems actually work? Which carriers walk the walk, and which ones just talk the talk? Let me give you the insider perspective.

We’ll analyze shipping routes, look at real transit times (not the estimated ones), and dig into reliability records. This helps you match your specific needs – shipping delicate ice cream versus, say, frozen peas – to the right carrier.

We’ll also explore up-and-coming options like regional specialists and innovative startups. These smaller players are often more nimble and offer personalized service that the big guys can’t. They’re disrupting the industry, often with impressive results.

To help you visualize the landscape, I’ve put together a comparison table:

Major Carrier Cold Chain Services Analysis

| Carrier | Service Type | Temp Monitoring | Coverage | Typical Cost | Reliability Rating |

|---|---|---|---|---|---|

| FedEx | Cold Chain | Real-time GPS & Temp Tracking | National | $$$ | 4/5 |

| UPS | Temperature True | Sensor-based tracking | National | $$$ | 4/5 |

| Example Regional Carrier | Frozen Freight | Data Loggers | Regional (Midwest) | $$ | 4.5/5 |

| Example Startup | Specialized Frozen Delivery | AI-Powered Predictive Temp Control | Select Cities | $$ – $$$ | 3.5/5 (Growing) |

Key Takeaways: Established players like FedEx and UPS provide broad coverage and reliable (though pricey) service. Regional carriers often offer a sweet spot of good reliability and competitive pricing. Startups are exciting, but their reliability and coverage are still developing. Choose wisely!

Temperature Monitoring That Actually Saves Your Shipments

Temperature monitoring is so much more than just a compliance checkbox. Think of it as your insurance policy, your safety net for your valuable shipments. I’ve seen firsthand how the right monitoring can completely transform a business, turning shipping nightmares into smooth sailing. It really boils down to having control and insight, preventing those costly losses that can keep you up at night.

There’s a wide range of options out there, from the super simple to the seriously high-tech. On the simpler side, you’ve got data loggers. These little guys can be found for under $20 and give you a complete temperature history of your shipment. This is crucial for spotting any temperature excursions that might happen in transit.

Choosing the right shipping method is key to keeping your frozen goods in top condition. Then you have the more advanced IoT (Internet of Things) devices. These offer real-time alerts straight to your phone, giving you instant visibility into your shipment’s temperature.

Think of it like this: you wouldn’t drive a car without a fuel gauge, right? Temperature monitoring is like the fuel gauge for the best way to ship frozen food, letting you know exactly how your precious cargo is doing along the way.

Real-World Impact

I’ve heard so many stories of shipping disasters averted thanks to temperature monitoring. One business owner I know got a real-time alert about a refrigeration unit malfunction during a cross-country shipment. Because of that alert, they were able to reroute the shipment and save thousands of dollars’ worth of product. It was a close call! Another company used data logger information to find a recurring temperature problem in their packaging. They tweaked their insulation and significantly reduced product loss.

Temperature data isn’t just about reacting to problems—it’s about preventing them in the first place. By analyzing your data, you can find trends and weaknesses in your shipping process. This lets you refine your methods, build better relationships with your carriers, and, best of all, build trust with your customers. They’ll know their order will arrive perfectly, every single time.

Leveraging Industry Growth For Better Shipping Results

The frozen food shipping industry is experiencing a real boom, and that creates some cool opportunities for businesses. From my experience working with logistics companies, I’ve seen firsthand how technology is changing the game for cold chain shipping. Big investments in things like predictive analytics are helping to reduce shipping failures. Think of it as a weather forecast, but for your shipments. It predicts potential delays or temperature problems before they happen, so you can make changes and ensure your frozen goods arrive perfectly.

Predictive analytics isn’t the only game-changer. Automated monitoring systems are also getting more advanced, which is helping lower costs across the board. These systems keep tabs on temperature, humidity, and even location in real-time. That kind of data is gold for optimizing shipping routes and preventing spoilage. Speaking of temperature, maintaining it is crucial. With this level of control, you can step in when needed, minimizing losses and running a tight ship.

This growth spurt in the industry also means more options for shippers. New specialized carriers and innovative startups are popping up, offering competitive rates and customized services. And the numbers speak for themselves: In 2024, the global frozen food logistics market was worth about $30.60 billion. It’s projected to reach $35.14 billion in 2025, which is a 14.8% CAGR. Technologies like predictive analytics and drone monitoring in cold storage are also playing a role in improving efficiency and reducing costs. This evolving market is a real opportunity for businesses that are willing to explore new options and find the best way to ship their frozen food. It’s all about being smart and using these industry changes to your advantage.

Your Personalized Shipping Success Strategy

Finding the perfect shipping strategy for frozen food isn’t a one-size-fits-all kind of deal. It’s about creating a system that works for your unique situation. After years of helping food businesses with their shipping, I’ve seen firsthand what separates the smooth operators from those constantly putting out fires. Let’s build a strategy tailored to your product, shipping volume, and budget.

Evaluating Your Needs and Options

First, we need to be absolutely clear on what you’re shipping. Are we talking delicate ice cream, robust frozen vegetables, or something in between? This impacts your temperature requirements and, ultimately, your shipping method. I’ve seen businesses make the mistake of assuming all frozen foods are the same, only to have meltdowns (literally!) later.

Next, consider your volume. Shipping a few hundred packages a month is a totally different ballgame than shipping thousands. One might call for a simple solution, while the other demands a more sophisticated approach. I’ve worked with businesses at both ends of the spectrum, and the strategies can vary dramatically.

Finally, let’s be realistic about your budget. There are economical choices and premium services, and we’ll find that sweet spot that gives you the best value. Don’t be afraid to explore all your options – you might be surprised at what’s available.

Practical Checklists for Success

Here are some handy checklists I’ve put together over the years. These aren’t just theoretical – these are based on real-world experience, the kind of stuff that actually works:

Carrier Evaluation Checklist:

- Cold Chain Capabilities: Does the carrier (FedEx is one example) truly understand frozen goods? Ask for references and get the inside scoop on their temperature-control methods. I’ve seen firsthand how a carrier with a shaky cold chain can ruin a shipment.

- Transit Times and Reliability: Don’t just take estimated delivery dates at face value. Dig deeper and get real-world performance data. A missed delivery window can mean the difference between a happy customer and a spoiled product.

- Monitoring and Tracking: What kind of temperature monitoring is offered? Real-time alerts are the gold standard, but even basic data loggers can provide valuable insights. I once saved a shipment by catching a temperature spike early thanks to a simple data logger.

Packaging Testing Checklist:

- Insulation Performance: Experiment with various insulation types (dry ice, gel packs, PCMs – there are lots of options!) to find the best fit for your product and shipping time. What works for a short trip might not cut it for a cross-country journey.

- Box Size and Fit: A snug fit is key for stable temperatures and preventing damage. Test out different box sizes and filler materials. You want your product to arrive safe and sound, not rattling around in a box.

- Leak Prevention: Good sealing and waterproof liners are crucial, especially for items that might thaw and create a mess. Nobody wants a soggy surprise!

Quality Control Checklist:

- Pre-Shipment Temperature Checks: Always double-check your product’s temperature before it leaves your facility. This simple step can prevent major headaches down the line.

- Regular Monitoring Data Review: Don’t just collect data; use it! Look for patterns and potential issues. Data can tell a story if you know how to listen.

- Carrier Communication: Set up clear communication channels with your carrier and address any temperature deviations immediately. A proactive approach can save a shipment from disaster.

These checklists are the foundation of a successful shipping strategy. We’ll help you avoid common mistakes, set realistic cost expectations, and develop a plan to scale your shipping as your business grows.

For reliable packaging, check out MrTakeOutBags.com for high-quality, affordable options to protect your frozen food during transit.

Comments are closed.