Understanding Why Insulated Food Packaging Matters Now

The world of food packaging has moved far beyond simple containers. These days, smart businesses know that insulated food packaging isn’t just a basic cooler anymore; it’s a critical part of their operation that can make or break their success. This is about more than just keeping things cold—it’s about adapting to a major shift in how people eat and what they expect.

Think about the journey your food takes. Whether it’s a gourmet meal kit traveling across the country or a hot lunch being delivered across town, your customers have one non-negotiable expectation: it has to arrive perfectly fresh. That expectation is a powerful driver, pushing everyone from local meal prep services to major food brands to get serious about their packaging. They get that the right packaging is a direct link to customer happiness and repeat business.

The Real Drivers of Change

So, what’s really pushing this change? It’s a mix of things that all point toward needing better temperature control. The massive growth of food delivery apps and direct-to-consumer food brands has introduced a whole new world of logistical puzzles. A soggy salad or a lukewarm soup isn’t just a small mistake; it’s a reason for a customer to click on a competitor for their next order.

On top of that, food safety rules are getting tighter. Keeping food at a consistent temperature isn’t just a good idea—it’s often a legal requirement to prevent foodborne illnesses. Businesses are realizing that spending on quality insulated food packaging is a smart move that protects both their customers and their reputation. The key motivations really boil down to a few core needs:

- Meeting Consumer Expectations: Creating a restaurant-quality experience for customers enjoying their meal at home.

- Ensuring Food Safety: Following strict temperature guidelines to stop food from spoiling.

- Reducing Waste: Cutting down on product loss caused by temperature changes during shipping.

- Strengthening Brand Image: Showing customers a clear commitment to quality and care.

This isn’t some small trend; it’s a huge market adjustment. The global market for insulated food containers was valued at USD 1.6 billion in 2020 and is expected to grow at an annual rate of 5.5% through 2025. This growth isn’t just a number; it reflects the real-world scramble from businesses trying to solve these exact problems.

Choosing Materials That Actually Work For Your Needs

Picking the right material for your insulated food packaging is a classic balancing act. It’s easy to just grab the cheapest option to save a few bucks, but that can quickly backfire with spoiled products and angry customers. On the other hand, the most advanced, expensive material might be overkill for a quick trip across town. The goal is to match the material’s capabilities to your actual shipping needs.

Understanding Insulation Performance

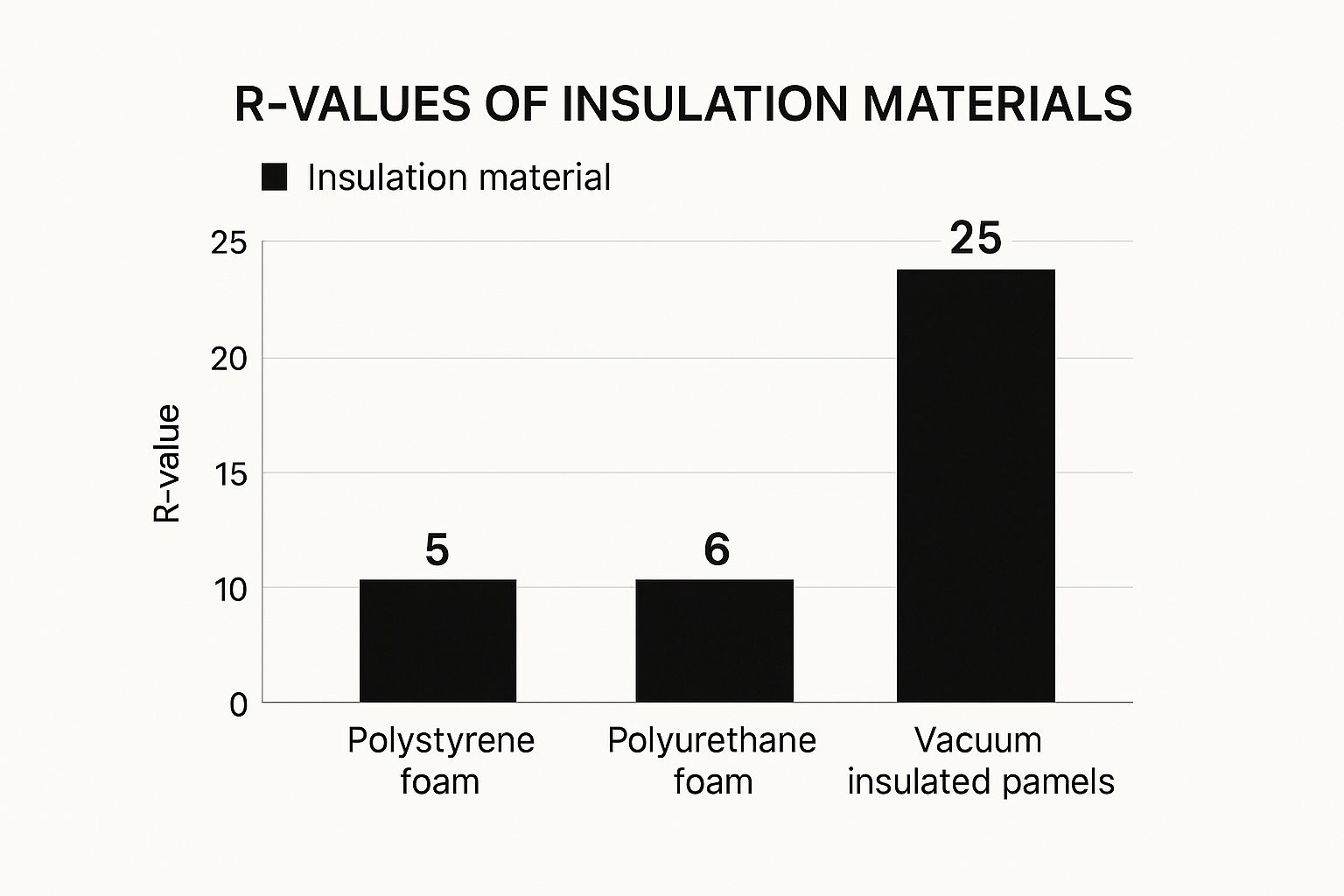

The effectiveness of an insulation material is measured by its R-value, which tells you how well it resists heat flow. Simply put, a higher R-value means better insulation. A meal kit company shipping frozen steaks across several states for a weekend delivery needs a much higher R-value than a local bakery delivering still-warm pastries.

This visual gives you a clear look at how common insulation materials stack up in terms of their thermal performance.

As you can see, there’s a huge performance gap between something like vacuum-insulated panels and standard foams. But performance is just one part of the story. You also have to factor in your budget, how long your products will be in transit, and your company’s sustainability goals. Expanded polystyrene (EPS) foam, for example, is a cost-effective workhorse, but its environmental impact is a significant concern for brands that prioritize being green.

To help you weigh these factors, here’s a breakdown of the most common materials.

Comparing Materials for Insulated Food Packaging

This table compares their performance, general cost, and environmental footprint to guide your decision.

| Material Type | Temperature Retention | Cost Range | Sustainability Rating | Best Use Cases |

|---|---|---|---|---|

| EPS Foam | Good (24-48 hours) | $ | Low (Difficult to recycle) | One-way shipping, cost-sensitive applications |

| Polyurethane (PUR) Foam | Excellent (48-96 hours) | $$$ | Moderate (Recyclable in some areas) | Multi-day shipping, high-value perishables, and pharmaceuticals |

| Vacuum Insulated Panels (VIPs) | Superior (96+ hours) | $$$$ | High (Reusable, but complex) | International shipping, clinical trials, extreme temperature control |

| Natural Fibers (Cotton, Jute) | Moderate (up to 48 hours) | $$ | High (Biodegradable, compostable) | Eco-conscious brands, meal kits, and short-duration shipping |

| Insulated Liners/Bags | Fair (up to 24 hours) | $ | Varies (Some are recyclable) | Local deliveries, grocery, and adding insulation to existing boxes |

This comparison highlights that there’s no single “best” material. The right choice depends entirely on your specific circumstances, balancing insulation needs with budget and brand values.

Matching Materials to Real-World Scenarios

Let’s look at how this plays out for two very different businesses:

- A National Meal Kit Service: This company ships boxes that will be in transit for 48-72 hours, filled with delicate proteins and fresh produce. For them, spending more on higher-performance options like polyurethane foam or even vacuum-insulated panels makes sense. The extra cost is an investment that prevents product spoilage, which would be far more expensive in refunds and lost customer trust.

- A Local Catering Company: They’re just delivering hot food for an event an hour away. A much simpler solution, like a durable insulated fabric bag or a standard foam cooler, is more than enough. Since the delivery window is so short, they don’t need to pay a premium for extreme, long-duration temperature control.

By honestly evaluating your needs against material performance and cost, you can find your ideal solution. Don’t just look at the upfront price; think about the total cost of ownership, which includes potential losses from deliveries that don’t go as planned.

Getting Your Packaging Size And Design Right

Choosing the right materials is a big win, but it’s only half the story. How you size and design your insulated food packaging is just as important. Picture this: you’re shipping a single, perfect frozen cupcake in a cooler box big enough for a whole cake. All that extra room, the air gap, is working against you. Air is a terrible insulator, and a large air gap means your gel packs are busy chilling the air instead of your product. This is a common misstep that can lead to melted goods and disappointed customers.

The Physics of a Perfect Fit

Your main goal should be a high product-to-container ratio. This simply means you want as little empty space as possible. By doing this, you let the product’s own temperature stability, or its thermal mass, do some of the work. It’s the same reason a full freezer stays cold longer than an empty one during a power outage. Your packaging needs to be just big enough to snugly fit your food and the coolants.

I’ve seen this principle work wonders for businesses shipping items with unusual shapes, like whole fish or wheels of artisanal cheese. Instead of just grabbing a standard box, they use custom-molded inserts or flexible insulated liners that hug the product’s contours. This smart move not only boosts thermal performance by cutting down on air gaps but can also slash shipping costs by reducing the package’s size and weight.

Smarter Design, Better Results

Beyond just getting the size right, a clever design can solve some tricky shipping puzzles. What if you need to ship frozen and refrigerated items together? Some businesses use modular systems. They create separate insulated compartments inside one box, using dividers to maintain different temperature zones. It’s a practical way to keep frozen steaks from accidentally freezing fresh veggies, ensuring everything arrives in perfect condition.

To nail your packaging strategy, here are a few tips from the field:

- Measure everything with precision: Don’t guess. Know the exact dimensions of your products, including their primary containers.

- Remember the coolants: Leave just enough room for gel packs or dry ice to surround the product effectively.

- Run some tests: Before you place a bulk order, do a few trial shipments. See how your setup performs under real-world transit conditions. It’s the best way to confirm your size and design choices are solid.

Mastering Temperature Control That Works in the Real World

Getting temperature control right is what separates successful food delivery operations from the rest. The difference often boils down to small, consistent actions that protect your food from the kitchen all the way to the customer’s hands. This process starts even before the food goes into the package.

Pre-Cooling and Smart Loading

One of the most effective yet frequently skipped practices is pre-cooling. Think of your insulated food packaging like a personal thermos. If you pour hot coffee into a room-temperature thermos, the container itself absorbs some heat, making your drink cool down faster. The same idea applies here.

Keeping your packaging in a chilled environment before packing ensures it doesn’t steal the cold from your food. For hot items, storing insulated delivery bags in a warm, dry area can help maintain that fresh-from-the-oven heat.

How you load your containers is just as crucial. The goal is to minimize empty space, much like a game of Tetris. This is where staff training really makes a difference. Here are a few proven methods:

- Place gel packs strategically—on the bottom, top, and sides—to create a “blanket” of cold air.

- Position frozen items at the bottom so the cold air can naturally sink and circulate.

- Use simple cardboard dividers to separate hot and cold items if they’re traveling in the same container.

Monitoring and Adapting

You can’t fix what you don’t measure. Using simple tools like temperature loggers can give you incredibly useful data. These small devices travel with a shipment, recording the temperature throughout the journey. This data shows if your packaging strategy is holding up or if there are weak spots, like a package sitting on a hot delivery truck for too long on a particular route.

This attention to detail is becoming more common as the market grows. The global insulated packaging market was valued at around USD 11.4 billion in 2020 and is expected to hit USD 15.8 billion by 2025, a jump driven by the increasing demand for temperature-sensitive shipping. By using these real-world temperature control methods, you not only protect your products but also build a reputation for quality and reliability.

Navigating Food Safety Rules Without Going Crazy

Following food safety rules isn’t just about dodging a fine; it’s about building the trust that keeps your customers coming back for more. When you’re shipping meals and other temperature-sensitive foods, your insulated food packaging is a critical line of defense in your safety plan—and you can bet regulators know it. The good news? Staying compliant doesn’t have to be a complicated mess.

Core Compliance: What Inspectors Look For

Inspectors from agencies like the FDA or your local health department are focused on one main goal: stopping foodborne illness before it starts. For packaged foods, this boils down to keeping products out of the “danger zone,” which is typically between 40°F and 140°F. This is the temperature range where bacteria can grow quickly, and it’s where your packaging and handling procedures get put under the microscope.

Having clear documentation is your best friend during an audit or inspection. This doesn’t mean you need a mountain of paperwork. Instead, focus on keeping simple but essential records.

- Temperature Logs: Keep consistent records from your temperature monitoring devices. This shows you’re actively tracking performance from your facility to the customer’s door.

- Supplier Certifications: Have files ready that show your insulated food packaging materials are certified as food-safe.

- Standard Operating Procedures (SOPs): These are just simple, written guides for your staff. They outline exactly how to pack orders to maintain the correct temperature, ensuring everyone is on the same page.

Staying Ahead of the Curve

Food safety regulations are always adjusting to new science and changing consumer habits. Being proactive will save you major headaches down the road. For instance, if you’re shipping through a heatwave, it’s smart to double down on your precautions.

Ultimately, a strong quality control system shows a real commitment to safety that goes beyond just checking boxes. It’s about protecting your customers and preserving your brand’s hard-earned reputation.

Smart Cost Management And Measuring What Matters

When it comes to insulated food packaging, grabbing the cheapest option off the shelf can feel like a win, but it’s often a fast track to losing money on spoiled products and dealing with unhappy customers. True cost management is about more than just the price per box. It’s about understanding the total cost of ownership—a figure that includes everything from the raw materials and shipping to labor costs and even the financial sting of a one-star review.

Think of it this way: a slightly more expensive box that’s designed for quick assembly can shave precious seconds off your packing time. Over thousands of orders, those seconds translate into significant labor savings. Similarly, investing in better insulation might bump your upfront packaging cost by 15%, but if that investment cuts your spoilage rate in half, you’ve made your money back and then some. The return is immediate and protects your bottom line.

Measuring What Truly Counts

To get the full picture, you need to track the real-world performance of your packaging. This means looking beyond basic expenses and focusing on the Key Performance Indicators (KPIs) that tell the whole story of your operation’s health.

Here are a few metrics that matter most:

- Spoilage Rate: This is the percentage of your products that are damaged or compromised because of temperature failures. It’s the most direct financial yardstick for your packaging’s effectiveness.

- Customer Complaint Frequency: How often are customers reaching out about food arriving at the wrong temperature or lacking freshness? This KPI is a direct line to your brand’s reputation.

- Labor Efficiency: Take a stopwatch to your packing line. How long does it actually take your team to assemble and pack an order? A streamlined process can be a hidden source of major savings.

To help you get a handle on these numbers, we’ve put together a framework for a cost-benefit analysis.

Key Metrics for Measuring Packaging ROI

This table outlines the key metrics and how to calculate them, giving you a clear path to evaluating the true return on your packaging investment.

| Cost Category | Calculation Method | Typical Range | Impact Level | Measurement Frequency |

|---|---|---|---|---|

| Material Costs | (Price per Unit) x (Total Units) | $0.50 – $5.00 per unit | High | Per Order/Batch |

| Labor Costs | (Time to Pack) x (Hourly Wage) | 30-90 seconds per box | Medium | Weekly/Monthly |

| Spoilage Rate | (Spoiled Units / Total Units Shipped) x 100 | 1% – 5% | High | Monthly |

| Customer Complaints | (Complaints / Total Orders) x 100 | < 2% | High | Weekly/Monthly |

| Return Shipping | Cost per returned item | $10 – $30 per return | Medium | As Incurred |

This table is a starting point. By regularly tracking these metrics, you can move from guessing what works to knowing what pays off. The goal is to see how an initial investment in quality packaging directly reduces long-term costs like spoilage and customer churn.

The demand for reliable temperature-controlled shipping isn’t slowing down. In fact, market projections show the insulated packaging industry growing from USD 17.71 billion in 2025 to a massive USD 29.00 billion by 2032. This surge highlights a global need for effective solutions in food delivery.

Funding these kinds of quality improvements is a common challenge. Many businesses look into various financing options to upgrade their packaging without a huge upfront capital expense.

Your Roadmap To Insulated Food Packaging Success

Now that you have a solid handle on the different materials, sizing options, and temperature control basics, it’s time to map out your strategy. Finding success with insulated food packaging isn’t about guesswork; it comes from a thoughtful, step-by-step approach. Breaking the process down into manageable phases helps avoid operational headaches and sets you up for success right from the start.

The Initial Assessment Phase

Before you even think about buying a single bag or box, you need to take a good, hard look at your current operations. This is your chance to collect the baseline data that will inform every decision you make down the line. What are your most common delivery distances and times? What are the specific temperature requirements for your menu items? You should also audit your current losses by tracking every spoiled or returned item due to temperature problems for a full month.

This audit gives you a clear picture of where you stand. For example, a bakery might discover that 90% of its deliveries are within a five-mile radius and take less than an hour. In that scenario, a simple insulated bag could be perfectly adequate. On the other hand, a seafood supplier shipping fresh fish overnight across three states will obviously need a more high-performance solution. This phase isn’t about finding the final answers; it’s about asking the right questions to guide your search.

Supplier Selection and Testing

With your needs clearly defined, you can start conversations with suppliers. Don’t just flip through a catalog. Ask for samples that fit your specific requirements and then put them through a real-world gauntlet. Pack your products exactly as a customer would receive them and send them out on your most difficult delivery routes.

- Test on your longest delivery route. This will show you the maximum stress the packaging can handle.

- Test during the hottest part of the day. Heat is your biggest enemy, so see how the packaging performs under pressure.

- Use temperature loggers to collect hard data. Don’t just guess if it “feels” cold enough. The numbers will tell the true story.

This testing phase is where you confirm if a supplier’s promises hold up. A solution that looks impressive on paper might fall short in the real world. The goal is to find a partner, not just a vendor—someone who understands your unique challenges and can deliver reliable packaging every time.

By following this practical roadmap—assessing your needs, finding the right partners, and testing everything—you can roll out a packaging program that protects your products, keeps your customers happy, and supports your business’s growth.

Ready to find the perfect packaging solution for your business? Explore our extensive collection of insulated food packaging at MrTakeOutBags.com and get the quality products you need with the personal service you deserve.

Comments are closed.