Understanding What Your Food Actually Needs

Many food businesses miss the mark from the start. I’ve seen it all – bakeries shelling out big bucks for heavy-duty frozen food packaging for cookies sold at room temperature, and seafood companies trying to save a few pennies with flimsy foam containers, only to end up with spoiled deliveries and unhappy customers. The real secret isn’t about buying the priciest insulated shipping boxes for food; it’s about figuring out what your products truly require.

This means asking the right questions. What’s the optimal temperature for your food? Are we talking frozen, refrigerated, or shelf-stable? A small ice cream company shipping across the country has completely different needs than a local meal kit service. Consider your shipping times. How long will your food be in transit? Fresh seafood needs overnight delivery, while a jar of jam can handle standard ground shipping.

Balancing Shelf Life, Seasons, and Smart Choices

Then there’s shelf life. Even with the best insulation, perishable items have their limits. Build in some buffer time for potential delays and temperature fluctuations. And don’t forget about seasonal changes. Shipping chocolate in the summer heat is a whole different ball game compared to shipping it in the winter. Speaking of which, the global market for insulated shipping boxes (for food and other industries) is expected to hit $8.5 billion by 2035, showing just how important temperature-controlled shipping is becoming. This just emphasizes how crucial it is to get your packaging right from the beginning.

Finally, learn from others’ experiences. Over-packing can be just as problematic as under-packing, affecting both your wallet and the environment. By carefully evaluating your specific needs, you can choose insulated shipping boxes that offer the best protection and save you money. Trust me, taking the time to understand your product will prevent major headaches (and unexpected expenses) in the long run.

Decoding Insulation Materials That Actually Work

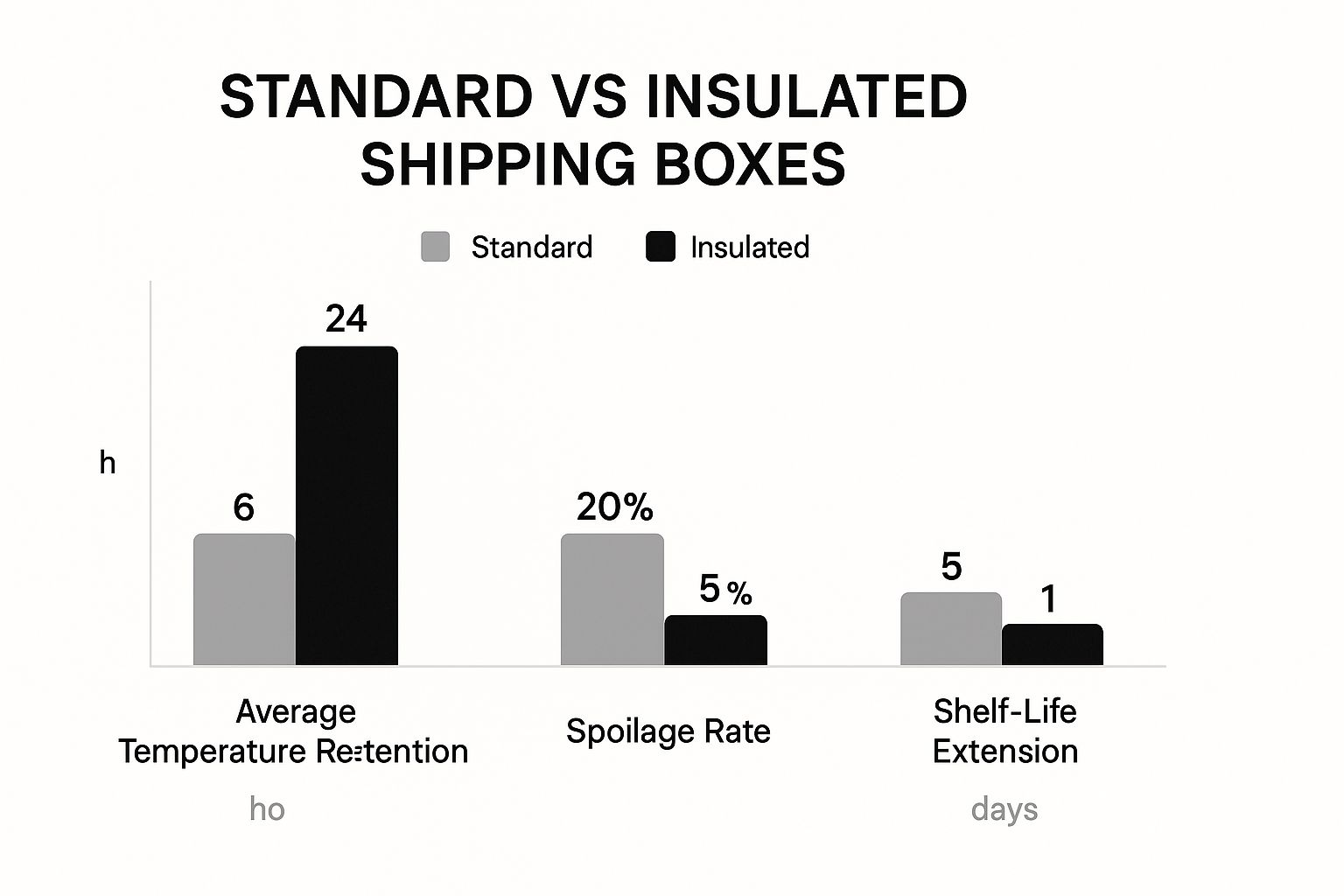

This infographic illustrates the difference between regular shipping boxes and insulated ones when it comes to food. The contrast is pretty stark: insulated boxes keep food fresh for an average of 24 hours, compared to a measly 6 hours in standard boxes. That’s a huge jump!

This longer freshness translates to a significantly lower spoilage rate – we’re talking 5% versus 20%. Plus, you get an extra five days of shelf life, which is a game-changer.

So, what’s the magic behind these insulated boxes? Let’s dive into the materials.

Exploring Insulation Options

Expanded polystyrene (EPS) is everywhere – it’s lightweight, cheap, and gets the job done. But let’s be honest, it’s not exactly a friend to the environment.

If you’re looking for a greener solution, especially for shorter trips, recycled denim or sheep’s wool insulation is worth considering. They’re natural, sustainable, and surprisingly effective.

For top-tier temperature control, Vacuum Insulated Panels (VIPs) are the gold standard. They offer incredible performance, but that premium quality comes with a higher price tag.

Then there are Phase Change Materials (PCMs) – the rising stars of temperature control. These materials absorb and release heat, keeping your products at a consistent temperature throughout their journey. They’re especially great for items that are super sensitive to temperature fluctuations.

To help you visualize the differences, I’ve put together this comparison table:

Insulation Material Performance Comparison

| Material Type | Temperature Range | Duration | Cost Level | Best For |

|---|---|---|---|---|

| Expanded Polystyrene (EPS) | Wide range | Moderate (up to 24 hours) | Low | General use, cost-sensitive shipments |

| Recycled Denim/Sheep’s Wool | Moderate range | Short-term | Medium | Eco-friendly, shorter distances |

| Vacuum Insulated Panels (VIPs) | Wide range, precise control | Long-term | High | Temperature-sensitive products, long-distance shipping |

| Phase Change Materials (PCMs) | Specific, consistent temperature | Moderate to Long-term | Medium-High | Pharmaceuticals, high-value perishables |

As you can see, each material has its own strengths and weaknesses. Choosing the right one depends on a few factors.

Choosing the Right Insulation for You

The ideal insulation for your food shipments depends on what you’re shipping, your budget, and how far it’s traveling.

Speaking of industry trends, the growth of the insulated shipping packaging market is being driven by changing food consumption habits and new technologies like PCMs and smart sensors.

Ultimately, finding the best insulation is a balancing act. You want something that protects your product, fits your budget, and aligns with your sustainability goals.

Getting Box Sizing Right Without Breaking The Bank

I’ve seen firsthand how choosing the wrong insulated shipping boxes can really hurt a food business. It’s a costly mistake, and it’s more common than you might think. It’s not as simple as just stuffing your product into a box; it’s about creating the right thermal envelope.

Too much space in the box, and you’re wasting precious insulation and paying extra for shipping volume you don’t need. Too little space, and you risk temperature swings that can spoil your product. Neither scenario is good for your bottom line.

Finding the Goldilocks Size

Getting the size right is all about finding the sweet spot for the product-to-air ratio. You need just enough air space for the insulation to do its job, but not so much that the temperature inside becomes unstable. Think of it like insulating your house—you don’t want drafts, but you also don’t want huge rooms that are difficult to heat or cool efficiently.

I had a friend who ran a gourmet cheese company, and he learned this the hard way. He started out using oversized boxes, thinking the extra space offered more protection. The opposite was true! The extra air actually made it harder to keep the cheese at a consistent temperature, and he ended up losing product and money due to spoilage. He finally downsized to more appropriately sized insulated shipping boxes, and it made a world of difference for both product quality and his shipping costs.

Considering Design Details

Beyond the overall box size, the little things can have a surprisingly big impact. Things like corner construction and lid sealing are crucial for preventing heat transfer and keeping a stable temperature inside. A poorly sealed lid can completely undermine even the best insulation. That’s why it’s worth investing in high-quality boxes with secure closures, even if they cost a little more upfront. Trust me, you’ll save money in the long run by avoiding spoiled product and returns.

Custom vs. Standard: Making the Right Choice

Sometimes, custom sizing is the only way to go, particularly for oddly shaped products or if you’re shipping in high volumes. But more often than not, adapting your packaging to fit standard sizes can be a smarter, more cost-effective solution. There’s a huge variety of standard insulated shipping boxes out there, and chances are you can find one that works for your product with a few tweaks to your internal packaging.

My advice? Experiment! Try out a few different configurations before you place a massive order. A simple test shipment with a few temperature loggers can give you a ton of valuable data on how your product fares in different box sizes. This small upfront investment in testing can save you major headaches (and money) later on.

Mastering Temperature Control For Your Specific Foods

Shipping food? It’s not a one-size-fits-all game. You can’t treat premium chocolates the same way you’d treat fresh seafood, even if both need a cool ride.

There’s a world of difference between, say, dairy and root vegetables. Dairy is way more sensitive to temperature changes. A few degrees can mean spoiled product and a refund request. And don’t forget humidity, airflow in your insulated shipping boxes for food, and how tightly things are packed.

Think about it: berries need to breathe to avoid mold, while frozen meat needs to stay frozen to keep its texture. Knowing the critical temperature ranges is crucial.

Handling the Unexpected

Shipping mishaps happen. Delays, temperature spikes, summer heatwaves…they’re all part of the game. Having a backup plan is essential. What if a shipment is delayed? What’s your plan for extreme weather?

I once worked with a small bakery that learned this the hard way. A summer storm delayed their cookie delivery. Standard ice packs in their insulated shipping boxes for food weren’t enough. Melted ice packs meant soggy cookies and unhappy customers. Now they use frozen gel packs in the summer and add a small “oops” gift to weather-delayed orders. Smart move for customer loyalty!

To help you get started, I’ve put together a handy table summarizing the temperature needs of various food categories. It includes optimal temperatures, acceptable ranges, and those all-important time limits. It’s a good starting point for building your own shipping strategy.

Food Category Temperature Requirements

| Food Category | Optimal Temp | Max Duration | Critical Notes | Common Issues |

|---|---|---|---|---|

| Dairy | 33-40°F (0.5-4.5°C) | 24 hours | Highly sensitive to temperature fluctuations. | Spoilage, off-flavors |

| Fresh Produce (Berries) | 32-40°F (0-4.5°C) | Varies, generally 3-7 days | Requires airflow. Sensitive to bruising. | Mold, softening, bruising |

| Frozen Meat | 0°F (-17.8°C) or below | Should remain frozen during transit | Avoid thawing and refreezing. | Texture changes, bacterial growth |

| Baked Goods (Cookies) | Room temperature for shelf-stable, cool for delicate items | Varies greatly depending on type | Consider humidity and potential for breakage | Staling, sogginess, breakage |

| Chocolate | Ideally below 70°F (21°C), avoid direct sunlight | Depends on the type | Sensitive to melting and blooming (white surface film) | Melting, blooming |

This table is a general guideline. Remember, specific needs can vary. Always research the precise requirements for your products. Doing your homework upfront saves headaches (and refunds) down the line.

Understanding your food’s unique needs is the first step. By anticipating the bumps in the road, you’ll keep your customers happy and your food in top condition.

Smart Technology That’s Actually Worth The Investment

The food shipping world is a whirlwind of new tech, but honestly, a lot of it solves problems you probably don’t have. I’ve seen it all firsthand, from simple temperature loggers to complex IoT systems. In my experience working with food businesses, I’ve learned what truly delivers. So, let’s ditch the flashy stuff and talk practical tech that makes a real difference.

Sometimes, the simplest solutions are the most effective. Temperature loggers, for example, are incredibly valuable. They’re a straightforward way to improve quality control and provide a temperature record during transit, crucial for spotting potential issues and proving compliance. They don’t have to break the bank either. You might be surprised at the insights you glean from this data!

When Advanced Tech Really Pays Off

For some businesses, real-time tracking with GPS and temperature sensors is a game-changer. This is especially true for those shipping high-value or highly temperature-sensitive items. Knowing the exact location and temperature of your insulated shipping boxes provides peace of mind and allows for quick action if needed.

Speaking of temperature control, if you’re using electric vehicles for delivery, optimizing temperature while maintaining fleet efficiency is key. It’s not essential for everyone, but for some, it’s indispensable.

Before you jump on the newest tech trend, remember that simplicity can be more efficient and cost-effective. Sure, things like AI-enabled temperature mapping and IoT-based monitoring are gaining traction and contributing to market growth. But ultimately, the best technology is the one that meets your specific needs and budget, not the latest fad. Choose tools that simplify your operations and boost efficiency, not complicate them. Sometimes, the simplest approach really is the best.

Building Supplier Relationships That Actually Support Growth

Finding the right supplier for your insulated shipping boxes for food is essential for long-term success. It’s not just about a one-time purchase; it’s about forging a real partnership that fuels your business growth. I’ve personally witnessed businesses thrive with the same packaging partner for years, while others bounce between suppliers, constantly hitting roadblocks. The key differentiator? Prioritizing long-term goals over immediate needs.

Consider scalability when evaluating potential suppliers. Can they handle your growth trajectory? A smaller supplier might be perfect for your current needs, but will they be able to keep pace if your order volume suddenly doubles or triples? Look for suppliers with a demonstrable track record of success, especially with businesses similar to yours. Have they helped other food companies scale? That experience is gold.

Customization is another critical factor. Are they open to collaborating with you to craft solutions tailored to your specific needs? Or are they just trying to push their standard products? This is where true partnerships are formed. A supplier who understands your business and invests in your success becomes an invaluable asset.

Red Flags, Market Shifts, and Long-Term Security

Keep an eye out for red flags, too. Is the supplier communicative and responsive? Do they consistently meet deadlines? Are they upfront about pricing and lead times? These seemingly minor details can often foreshadow larger issues down the line. A solid supplier relationship is founded on trust, reliability, and open communication.

Speaking of growth, the insulated packaging market in North America is expected to expand significantly in the coming years, largely fueled by the growth of e-commerce and home delivery for perishable goods. This makes finding a supplier who can adapt to this evolving market even more crucial.

Finally, think about supplier diversification. Consolidating with one supplier can streamline things, sure, but working with multiple vendors can help mitigate risk. If one supplier encounters disruptions, you have a backup ready to go. It’s a balancing act, but a diversified supplier network can provide a real competitive edge. Ultimately, building strong supplier relationships is a direct investment in the future of your business. It’s about finding partners who truly understand your vision and can help you bring it to life.

Your Roadmap To Food Shipping Success

Let’s get down to brass tacks. This isn’t about generic advice; it’s about a practical plan you can use right now to improve your food shipping game. Think of this as your personalized navigation system for the world of insulated food shipping.

Evaluating Your Current Packaging

The first step is taking an honest look at your current packaging situation. Are you seeing a lot of spoiled food? Are customers complaining about temperature issues? And are shipping costs eating into your profits? These are all red flags that signal a need for change. A simple checklist like this can be incredibly helpful:

- Temperature Consistency: Are your products showing up at the right temperature?

- Shipping Costs: Are oversized boxes or ineffective insulation breaking the bank?

- Customer Feedback: What are your customers saying about their deliveries? Are they happy?

- Sustainability: How eco-friendly is your current packaging? Could you be doing better?

These questions can help you zero in on the areas that need the most attention. And speaking of responsibility, think about how you can reduce supply chain carbon emissions. It’s not just good for the planet; it’s good for business, too.

Setting Realistic Benchmarks and Timelines

Once you know what needs fixing, set some realistic goals. For example, if your spoilage rate is at 10%, try to get it down to 5% in the next three months. Use concrete metrics, like temperature data and customer feedback, to track your progress. Remember, Rome wasn’t built in a day. Meaningful change takes time, so be patient and persistent.

Troubleshooting Common Challenges

Let’s be real, unexpected issues happen. Shipments get delayed, temperatures swing, and sometimes, customers complain. Knowing how to handle these situations is key. Having a plan for delayed shipments, like offering refunds or resending orders, can turn a negative experience into a positive one. And understanding how to deal with seasonal changes—like adding extra insulation in the summer and heat packs in the winter—can prevent costly losses.

Optimizing Packaging Costs Without Sacrificing Quality

Better packaging doesn’t have to mean bigger expenses. In fact, optimizing your box sizes and insulation materials can often save you money. Choosing the right size insulated shipping boxes for food, along with the most efficient insulation, can cut down on wasted space and weight, resulting in significant savings. It’s all about striking the right balance between protecting your product and managing costs.

Ready to take your food shipping to the next level? Check out MrTakeOutBags.com. They have a wide selection of high-quality, customizable packaging solutions perfect for food businesses. From insulated boxes to eco-friendly options, they can help you deliver your products fresh, safe, and on time, every time.

Comments are closed.