The Evolution of Packaging for Baked Goods

From humble paper bags to intricate designs, baked goods packaging has come a long way. Initially, its main purpose was simple: protection. Think back to the plain paper bags used by neighborhood bakeries years ago. But as consumer habits and market demands evolved, so did the function of bakery packaging. This journey reflects advancements in materials and technology, and also changing consumer preferences.

From Function to Brand Identity

Early bakery packaging prioritized containing the product and making transportation easy. Waxed paper and basic cardboard boxes were the standard. These provided a fundamental level of protection but lacked visual appeal. As competition grew, however, the need for packaging to convey brand identity and product quality became clear. Packaging began its transformation into a marketing tool.

The Rise of Preservation Technology

Technological progress has greatly improved food preservation. Modified Atmosphere Packaging (MAP), for example, regulates the environment inside the package, maximizing shelf life. These innovations respond directly to consumer demand for freshness and convenience, fueling the growth of the packaging market. This demand drives the need for longer-lasting baked goods.

Market Growth and Projections

The market for baked goods packaging is booming, fueled by consumer desires for both quality and convenience. As of 2025, the market is valued at USD 3.89 billion. Projections show it reaching USD 5.93 billion by 2034, with a 4.8% Compound Annual Growth Rate (CAGR). This growth is driven by innovations in materials and design that address both preservation and sustainability.

Sustainability and the Future of Packaging

Today, sustainability is paramount in packaging design. Consumers are increasingly eco-conscious, demanding environmentally friendly choices like biodegradable and compostable materials. This isn’t a fad; it’s a core value shift. The challenge for bakeries is balancing sustainability with product protection and attractive presentation. This represents the next step in the evolution of baked goods packaging: a fusion of innovation and responsibility.

Choosing Materials That Truly Protect Your Creations

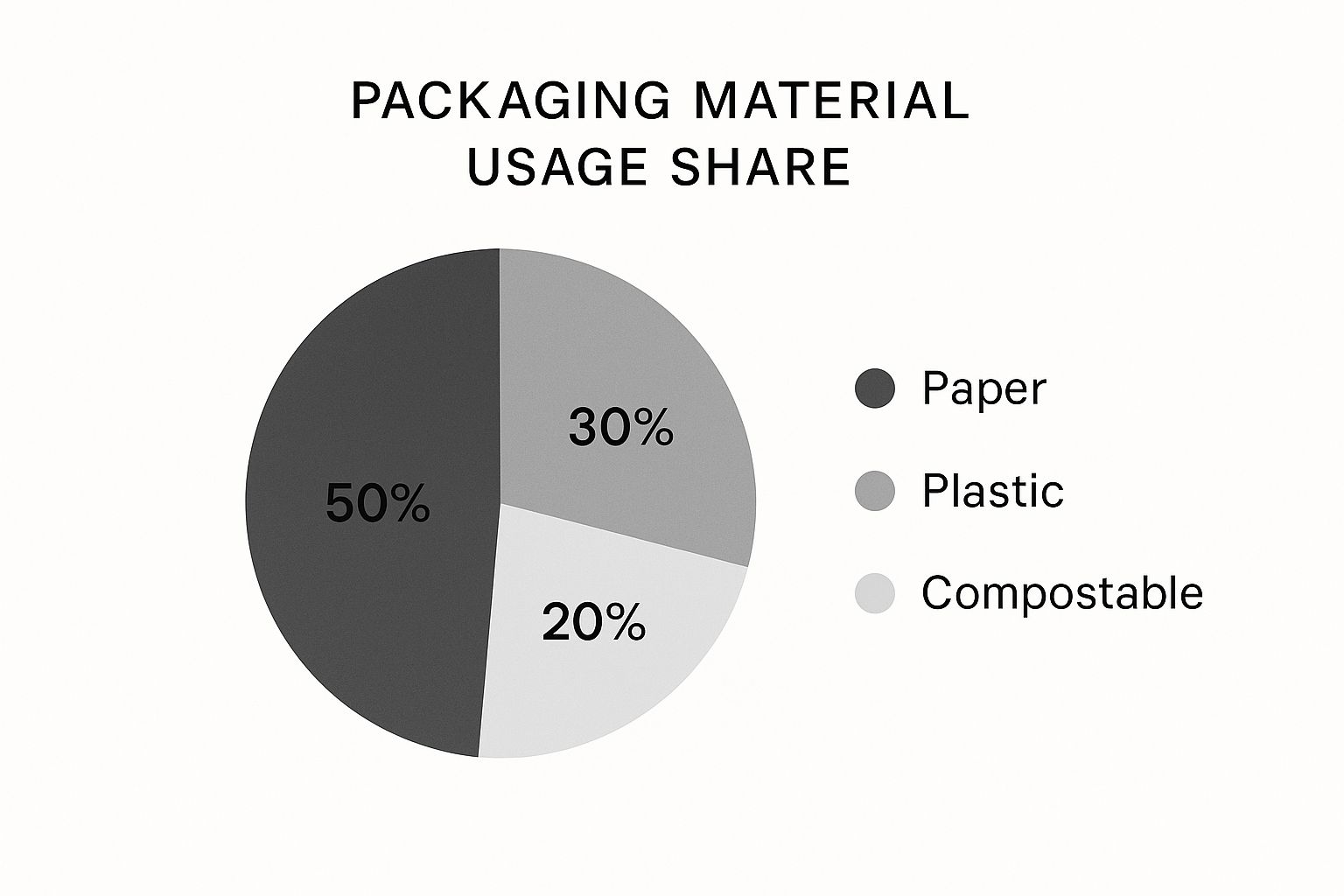

The infographic above illustrates the current market share of different packaging materials, categorized into paper, plastic, and compostable options. Paper-based packaging holds a significant portion, followed by plastic, with compostable materials steadily increasing. This shows the baking industry’s movement towards sustainability, even with traditional materials remaining common. Selecting the right material is vital to ensure your baked goods arrive perfectly. This means understanding material interactions with your specific products.

Matching Material to Product

Different baked goods have unique packaging needs. A delicate, frosted cake needs different protection than a crusty loaf of bread.

Moisture is a major culprit in baked goods’ spoilage, causing sogginess and affecting quality. Therefore, moisture-resistant barriers are crucial for products like cakes, pastries, and certain cookies. This might involve greaseproof paper liners inside boxes or plastic containers with tight-fitting lids.

Some baked goods, like crusty breads, need breathable packaging to prevent condensation and keep their texture. Paper bags or boxes with ventilation holes are ideal here. These allow excess moisture to escape, preventing a soggy crust while still protecting the bread. Choosing the wrong material can negatively impact product quality and customer satisfaction.

Considering the Environmental Impact

With growing environmental awareness, sustainable packaging is in higher demand. Biodegradable and compostable packaging options are rising in popularity, offering eco-friendly alternatives. However, it’s important to evaluate their suitability for your products. Some compostable materials might not offer enough moisture or grease resistance for certain baked goods.

Balancing Protection, Presentation, and Cost

Packaging material selection involves balancing protection, presentation, and cost. The material must protect your product effectively while also looking appealing to customers. Cost is a major factor, particularly for small businesses. While premium packaging can boost your brand, finding cost-effective solutions that don’t compromise quality is essential.

Exploring Material Options: A Detailed Look

To help illustrate the differences between various packaging materials, we’ve compiled the following table:

| Material Type | Best For | Moisture Resistance | Grease Resistance | Environmental Impact | Cost Range |

|---|---|---|---|---|---|

| Paperboard | Cakes, cookies, pastries | Moderate | Moderate | Recyclable | Low-Medium |

| Kraft Paper | Bread, muffins, simpler items | Low | Low | Compostable, Recyclable | Low |

| Plastic (PET/PLA) | Cakes, delicate pastries | High | High | Recyclable (PET), Compostable (PLA) | Medium-High |

| Biodegradable Films | Various, depending on the film | Varies | Varies | Compostable | Medium-High |

This table summarizes the pros and cons of common packaging materials, highlighting the need to consider each material’s properties before deciding. Understanding these nuances is key to preserving your creations and presenting them effectively.

Freshness-First Design: Beyond Basic Protection

Packaging for baked goods isn’t just about containment; it’s about preserving the delightful flavors and textures that customers love. This means understanding how design choices significantly affect shelf life. Even a small adjustment to the closure can be the difference between a fresh pastry and a stale one. Let’s explore the science of preserving freshness through thoughtful design.

Moisture Control: The Key to Long-Lasting Treats

Moisture is a primary culprit in baked goods going stale. And moisture control involves choosing packaging materials and designs that prevent unwanted moisture gain or loss. This could mean utilizing moisture-resistant barriers, such as waxed paper liners for cakes, or placing desiccants inside cookie packaging.

Also, think about the environment where your products are stored and displayed. High-humidity locations, for example, will necessitate stronger moisture protection.

Strategic Ventilation: A Breath of Fresh Air for Your Products

While some items need protection from moisture, others, like crusty breads, actually require strategic ventilation. Tiny holes in the packaging allow excess moisture to escape, preventing a soggy crust while still safeguarding the loaf.

Finding this balance is essential for extending shelf life and maintaining ideal textures. Similar techniques are used for certain cookies to retain their crispness.

Structural Integrity: Protecting Your Products From Crushing

Even with proper moisture control and ventilation, structural integrity is paramount. This means using durable materials that can handle stacking and movement without damaging the contents. Consider the entire journey of your product, from your oven to the consumer.

Reinforced corners, custom inserts, and right-sized boxes are key to preserving your product’s appearance, which is nearly as important as taste. The global problem of food waste, with one-third of all food produced lost or wasted every year, emphasizes the importance of effective packaging. Durable and sufficient packaging prevents contamination during shipping and storage, ensuring your products remain appealing throughout their shelf life.

Freshness Solutions for Small Bakeries

Implementing effective preservation methods doesn’t always require expensive equipment. Smaller bakeries can use strategies like vacuum sealing individual portions or incorporating oxygen absorbers in smaller packages.

This allows smaller businesses to maintain product longevity, competing effectively with larger producers. These investments showcase a commitment to quality and freshness, boosting both customer satisfaction and brand loyalty. These small steps can significantly improve your brand image and perceived quality.

Sustainable Packaging That Actually Works

Consumers are increasingly aware of their environmental impact and expect businesses to follow suit. This includes a growing demand for sustainable packaging. However, bakeries face the unique challenge of balancing eco-friendliness with the critical need to protect their delicate products. This section explores practical strategies for implementing sustainable packaging that safeguards both your baked goods and the planet.

Biodegradable vs. Compostable: Understanding the Difference

Compostable and Biodegradable are often used synonymously, but they have distinct meanings. Biodegradable materials break down naturally. However, this process can be slow in landfills, releasing methane, a potent greenhouse gas. Compostable materials, on the other hand, decompose into organic matter under specific conditions within a composting system.

This distinction is crucial for bakeries. A compostable box might be perfect for cookies, but not for a moist cake, where the packaging could degrade prematurely. Selecting the appropriate material is key to minimizing environmental impact. Furthermore, government regulations and consumer demand are driving the development of innovative, sustainable packaging solutions. Major packaging companies are investing in research and development of biodegradable materials and ‘smart’ packaging to address these evolving needs.

Real-World Performance of Eco-Friendly Alternatives

Several sustainable materials perform exceptionally well for baked goods. Plant-based plastics (PLA), made from corn or sugarcane, provide compostable alternatives to traditional petroleum-based plastics, offering suitable protection for items requiring moderate moisture control. Mushroom packaging, crafted from agricultural waste and mycelium (mushroom roots), is an emerging option that offers excellent cushioning and insulation for delicate treats.

However, not all sustainable materials offer the same performance. Some biodegradable options lack the necessary grease resistance for buttery pastries, while others may not withstand temperature fluctuations. Thorough testing with your specific products is essential to ensure suitability.

Reducing Packaging Waste: Beyond Material Choice

Sustainability extends beyond material selection to minimizing waste. Right-sizing your packaging is a simple yet impactful strategy. Using the smallest necessary box or bag reduces material consumption and shipping expenses. Reusable containers, encouraging customers to return packaging for refills, foster a sense of community while minimizing waste. Implementing a closed-loop system, where packaging is collected, cleaned, and reused, is a more advanced approach gaining traction among some bakeries.

Communicating Your Sustainable Choices

Transparency is paramount. Consumers want to understand your brand’s values, including your packaging choices. Communicate your sustainability initiatives clearly on your packaging, website, and other marketing materials. Highlighting the use of compostable materials or a waste reduction program builds trust with environmentally conscious customers, strengthening your brand image and demonstrating your commitment to responsibility. Sustainable practices benefit both the planet and your bottom line.

To help you further evaluate your options, here’s a look at different sustainable packaging materials:

Sustainable Packaging Options for Bakeries

| Packaging Type | Material Source | Compostability | Moisture Protection | Best Applications | Consumer Reception |

|---|---|---|---|---|---|

| PLA-lined boxes | Plant-based plastic (PLA) & recycled paperboard | Compostable lining, recyclable box | Moderate | Cakes, pastries, cookies | Positive, perceived as eco-friendly |

| Mushroom packaging | Mycelium & agricultural waste | Fully compostable | High, good insulation | Delicate pastries, breads | Growing interest, unique appeal |

| Molded fiber containers | Bagasse (sugarcane fiber) | Compostable | Moderate | Cookies, muffins, single-serve items | Positive, readily available |

| Glassine paper bags | Wood pulp | Recyclable, biodegradable | Low, grease-resistant | Cookies, candies, dry goods | Traditional, familiar |

| Reusable metal tins | Metal | Reusable, recyclable | High, airtight | Cookies, specialty items | Positive, perceived as high-quality |

Key takeaways from this table include the increasing viability of compostable options like PLA and mushroom packaging, alongside the continued relevance of traditional materials like glassine paper when paired with proper recycling practices. The positive consumer reception toward sustainable options underscores the importance of adopting these practices.

Packaging That Tells Your Story and Sells Your Products

Packaging for baked goods has come a long way. It’s no longer just about containing the product; it’s a vital part of brand storytelling. Packaging communicates your values, the quality of your goods, and ultimately, convinces customers to choose your bakery. This involves careful consideration of design, materials, and the overall customer experience.

Visual Elements That Drive Sales

The look of your packaging often forms a customer’s first impression. Color psychology plays a key role. Warm colors, such as red and orange, evoke feelings of comfort and excitement, perfect for cookies or holiday treats. Cool colors like blue and green suggest freshness and natural ingredients, which might be better suited for health-conscious baked goods.

Typography also communicates your brand’s personality. A playful font might fit a whimsical cake shop, while a classic, elegant font might be better for a high-end bakery. Think of your packaging as a tiny billboard, instantly showing what makes your shop special.

Communicating Your Brand Story

Effective packaging tells a story about your brand and products. Imagine a bakery specializing in locally sourced ingredients. Packaging made from recycled materials and decorated with images of local farms reinforces that local connection with customers.

Consider sustainable promotional items to further connect with environmentally conscious consumers. This strengthens your brand’s commitment to sustainability. Similarly, vintage-inspired designs could highlight a bakery’s history and treasured family recipes, letting your packaging reflect the core of your business.

Enhancing Perceived Value Through Packaging

High-quality packaging significantly impacts perceived value. Imagine two similar cookies: one in a plain plastic bag, the other in a beautifully designed box. Which one seems more appealing?

This is particularly important in a competitive market. Investing in premium packaging elevates your brand image and justifies higher prices. Customers often happily pay more for beautifully presented products.

Building Brand Loyalty Through Packaging

Packaging plays a large part in brand loyalty. Positive experiences, including the packaging, encourage repeat purchases and help customers remember your brand.

Small details can surprise and delight customers, like a handwritten thank-you note or a custom sticker. These create memorable moments that build loyalty and encourage word-of-mouth referrals. By 2023, the global bakery industry reached a market size of $513.17 billion, projected to hit $919.9 billion by 2032. This shows the importance of aligning packaging choices with market trends. This growth is fueled by changing consumer preferences, including a desire for healthier, more sustainable products, highlighting the role packaging plays in reflecting these trends.

Channel-Specific Packaging for Maximum Impact

Why does seemingly identical packaging sometimes fly off the shelves in a retail store, yet fall flat when shipped? The answer often lies in the distribution channel. Each channel, from brick-and-mortar displays to e-commerce deliveries and wholesale partnerships, presents unique packaging requirements for baked goods. Understanding these nuances is crucial for maximizing your product’s impact and ensuring it arrives in perfect condition.

In-Store Strategies: Enticing Impulse Buys

In retail, your packaging does the talking. It’s your silent salesperson, responsible for grabbing attention, communicating quality, and ultimately, encouraging impulse purchases. Think vibrant colors, captivating designs, and packaging that allows the product to be clearly visible. For example, a bakery might choose windowed boxes to display their artfully decorated cupcakes, tempting customers with a peek at the sweetness within. Consider also how your packaging will compete on the shelf. Smart use of shape, size, and material can transform your product into the star of the bakery aisle.

E-Commerce Essentials: Safeguarding During Transit

E-commerce brings its own set of packaging considerations. Here, protection reigns supreme. Your packaging needs to endure the bumps and bruises of shipping while creating a positive unboxing experience. This usually involves sturdy boxes, protective inserts, and tamper-evident seals. For fragile treats like macarons, specialized inserts become essential, cradling each delicate cookie during its journey. Don’t overlook presentation. A beautifully packaged product, even for shipping, builds brand loyalty and leaves a memorable impression.

Wholesale Wisdom: Balancing Protection and Professionalism

Wholesale packaging often demands a practical approach. While presentation still matters, efficiency and cost-effectiveness take center stage. This might mean simpler designs, larger quantities, and materials designed for stacking and storage. Product protection is still paramount. Durable boxes and clear labeling are vital for preserving product quality throughout the supply chain. The key is to strike a balance, ensuring easy handling while guaranteeing your goods arrive fresh and undamaged.

The global confectionery and bakery packaging market is significantly shaped by factors such as urbanization and the rise of e-commerce, especially in areas like Asia Pacific and Latin America. By 2024, this market had reached USD 120.01 billion and is projected to hit USD 182.62 billion by 2033, growing at a CAGR of 4.54%.

Adaptable Packaging Systems: Streamlining Across Channels

Creating separate packaging for every channel can become costly and complicated. This is where adaptable packaging systems shine. Imagine a core box design that can be modified with various labels, inserts, or ribbons depending on the distribution channel. This strategy helps maintain consistent branding while tailoring the packaging to each channel’s specific requirements. It maximizes efficiency without sacrificing impact, allowing your brand to stand out no matter where your products are sold. This approach streamlines operations and ensures maximum impact across all sales channels.

Smart Budget Strategies for Packaging That Performs

Attractive and functional packaging is crucial for baked goods. But creating eye-catching packaging doesn’t have to break the bank. Smart bakeries use clever strategies to manage packaging costs without sacrificing quality or visual appeal. This involves carefully examining every step of your packaging process, from the materials you choose to how efficiently your team assembles the final product.

Material Costs: Getting the Most for Your Money

Bulk purchasing can offer substantial savings, especially for items you use frequently, such as boxes or bags. Negotiating discounts with your suppliers based on volume commitments can lower your per-unit cost. However, it’s important to balance bulk buying with your storage space and the potential for items becoming obsolete. For instance, custom-printed packaging with seasonal themes might not be suitable for large orders due to its limited shelf life.

Versatile packaging systems can also help reduce expenses. Using a standard box size for several different products simplifies inventory management and potentially unlocks volume discounts. This might involve using dividers or inserts to fit various baked goods within the same box, eliminating the need for multiple box sizes.

Beyond Materials: Optimizing the Entire Process

Look beyond the price of materials. Labor efficiency also has a significant impact on your budget. Packaging that is quick and easy to assemble reduces labor time, resulting in long-term savings. For instance, pre-folded boxes or self-sealing bags can significantly speed up the packaging process, especially during busy periods.

Waste reduction is another key factor. Minimizing material waste through careful cutting and optimized design saves both money and resources. Choosing appropriately sized packaging for your products avoids unnecessary material usage, while opting for recycled or recyclable materials helps lessen your environmental impact.

The Value of Customer Loyalty

Don’t underestimate how much good packaging can contribute to customer loyalty. While premium packaging might have a higher initial cost, it can enhance the perceived value of your goods and create a memorable experience that encourages repeat business. This long-term benefit can be more cost-effective than continually trying to attract new customers through pricey marketing efforts. A small touch like a branded sticker or a handwritten thank-you note can create a lasting positive impression.

By considering these factors, you can develop packaging solutions that maximize value while protecting your profits. Remember, smart budgeting isn’t about finding the absolute cheapest option. It’s about finding the optimal balance of quality, performance, and cost-effectiveness.

Ready to improve your baked goods packaging without overspending? Explore the wide array of high-quality, cost-effective packaging options at MrTakeOutBags.com. Our expert team can help you find the perfect packaging to fit your specific needs and budget.

Comments are closed.