Why Most Baked Goods Arrive as Disappointments

I’ve witnessed countless beautiful baked creations arrive at their destination as a sad, crumbled mess. It’s a common issue: bakers often don’t fully grasp the rough journey their treats endure during shipping. Those cookies aren’t magically teleporting from your oven to a happy customer. They’re on a bumpy, often chaotic ride in trucks, warehouses and are subjected to wild temperature swings. That’s why understanding the best way to ship baked goods is so important; without the right approach, even the most carefully crafted treats can arrive in disappointing condition.

This leads to unhappy customers because we often treat baked goods like any other shipment. But successful bakeries that ship across the country know the real enemies of a perfect delivery: vibration, humidity, and temperature changes. Vibration transforms delicate cookies into crumbs, humidity creates the dreaded soggy bottom, and fluctuating temperatures can melt frosting into a sticky goo. Imagine perfectly decorated sugar cookies arriving as a box of broken pieces – a baker’s nightmare!

This is why figuring out the best shipping method for your baked goods is so vital. It’s not just about getting them there fast; it’s about preserving quality and ensuring your product arrives intact. The global bakery market is booming – it was valued at $513.17 billion in 2023 and is expected to hit $919.9 billion by 2032. Online sales are a huge part of this growth. Customers want easy access to special treats through e-commerce, which makes successful shipping even more crucial.

Successfully shipping baked goods relies on understanding and addressing these shipping challenges. It’s about respecting the entire journey, not just the destination.

Packaging Materials That Actually Protect Your Creations

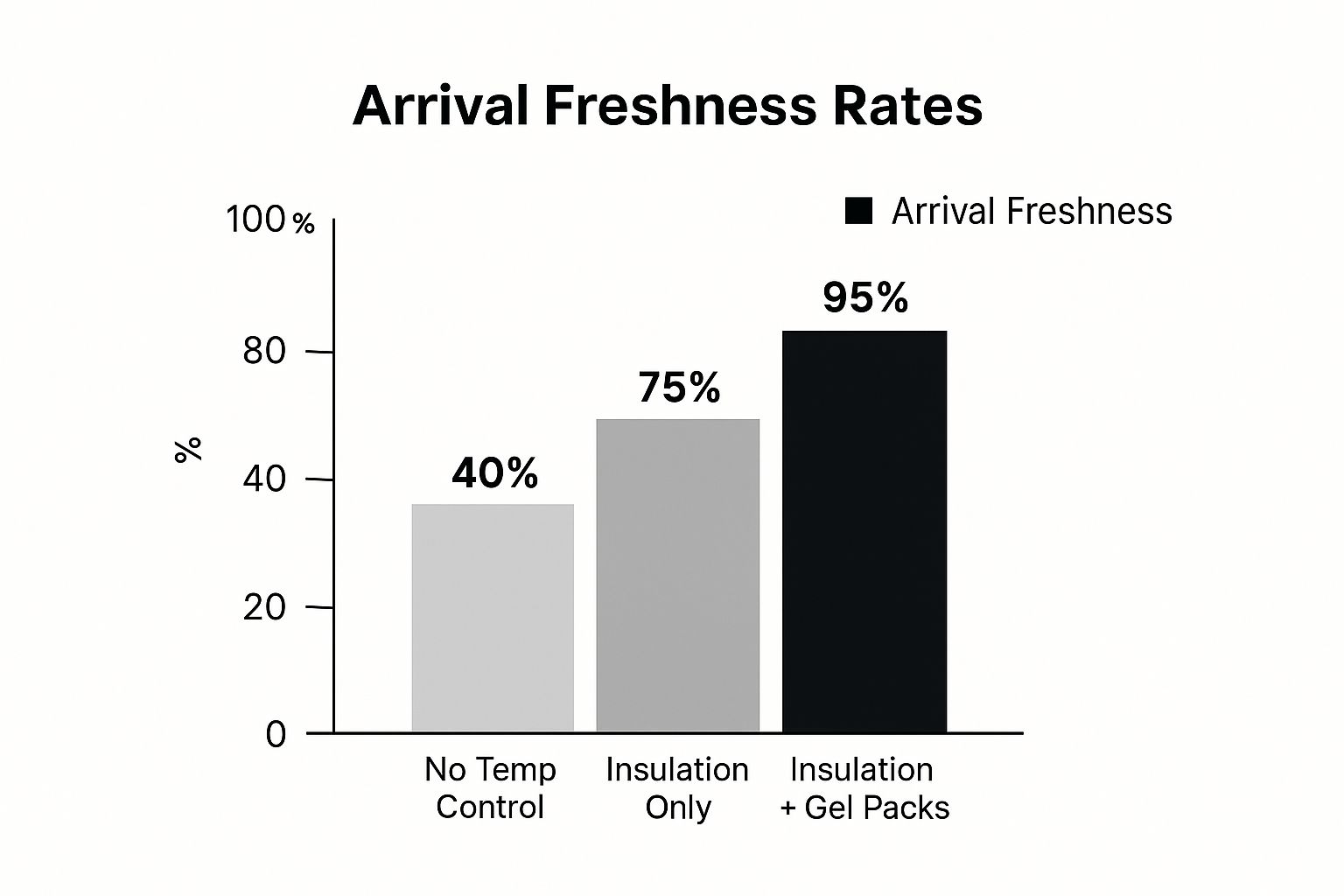

This infographic shows how different temperature controls affect the freshness of baked goods upon arrival. Notice the huge jump in freshness just by adding insulation! And with gel packs? A whopping 95% freshness rate. Trust me, this isn’t just marketing fluff – it’s about making sure your beautiful creations arrive in perfect condition and your customers are thrilled.

Picking the right packaging is key. Insulated boxes or liners create a stable temperature, essential for delicate treats. Personally, I’ve had great success with corrugated cardboard inserts for added protection against bumps during shipping. And don’t forget about moisture! Especially for delicate items like macarons, silica gel packets can be a lifesaver.

Cushioning is Key for Delicate Treats

The right cushioning is just as important. I use air pillows for lighter items and sturdy foam inserts for heavier cakes. It’s all about finding what works best for your specific products. For my multi-tiered cakes, I even use custom-cut cardboard inserts to prevent them from shifting during transit. It’s about how all these materials work together to create a haven for your baked goods.

The Industry is Catching On

It’s exciting to see how much the industry is prioritizing shipping quality. Recent surveys show that over 60% of bakeries shipping nationally or internationally invest in advanced logistics like next-day shipping. That’s a serious commitment to quality and happy customers. And in major markets, the use of insulated packaging has skyrocketed by over 45% in the last five years. It’s a trend I’m happy to be a part of. Think of your packaging as a microclimate, protecting your creations from the bumps and temperature swings of the shipping journey.

The following table summarizes some key considerations when choosing your packaging materials:

Packaging Materials Comparison for Different Baked Goods

| Material Type | Best For | Temperature Control | Cost Level | Durability |

|---|---|---|---|---|

| Corrugated Cardboard | Sturdy cakes, cookies | Moderate | Low | High |

| Insulated Box Liners | All baked goods | High | Medium | Medium |

| Air Pillows | Lightweight cookies, muffins | Low | Low | Low |

| Foam Inserts | Heavier cakes, cheesecakes | Moderate | Medium | High |

| Silica Gel Packets | Moisture-sensitive items (macarons, etc.) | N/A | Low | N/A |

As you can see, each material has its strengths. Think about what you’re shipping and what level of protection it needs. For example, those delicate macarons? Silica gel packets are a must. Shipping a heavier cake? Foam inserts and a sturdy box are your best bet.

Temperature Control Secrets That Professional Shippers Use

Shipping baked goods? It’s not as simple as throwing them in a box and hoping for the best. Trust me, I’ve seen firsthand how temperature control can make or break a shipment. Those delicious treats will face unpredictable conditions – from hot delivery trucks to “refrigerated” warehouses that might not be as cold as advertised.

Professional shippers understand that the key is designing packaging that can handle these real-world scenarios. This means getting a grasp on thermal mass and recognizing that insulation isn’t always the hero it seems to be. I’ve worked with bakeries where we’ve seen how basing cooling calculations on actual transit times (not just estimated delivery windows) can be a game-changer.

The Balancing Act of Insulation

Think of insulation as a temperature stabilizer. It slows things down, which is great for keeping heat out. But if your goods start cold, insulation will actually keep them cold longer than you might want. This is where gel packs come into play. They add thermal mass, absorbing and releasing temperature gradually to keep the environment inside the package more consistent.

Room Temperature vs. Refrigerated Shipping

Here’s a counterintuitive tip: sometimes, room temperature shipping is better than refrigerated. Imagine shipping cookies across the country in winter. A refrigerated truck could freeze them solid! Knowing your product’s temperature tolerance is crucial.

Also, consider the destination. If your customer lives in a hot climate, even refrigerated shipping might not be enough without extra measures. For really perishable items, you might even need dry ice. Effective temperature control is about creating a little microclimate for your baked goods, ensuring they arrive as delicious as when they left your kitchen.

Tailored Techniques for Every Type of Baked Good

Shipping baked goods successfully is a real art, and honestly, experience is the best teacher. Every treat has its own quirks and needs. What works for a sturdy cookie might crush a delicate macaron. Think you can ship a tiered cake the same way you ship a cupcake? Think again.

I’ve learned a lot through trial and error (and a few shipping mishaps!). Cookies, for instance, need protection from bumps and jostling during transit but are less sensitive to temperature changes. Cream-filled pastries? Totally different story. They’re like Goldilocks – they need everything just right, especially humidity and temperature. And multi-tiered cakes? Those require serious structural support to prevent shifting while still allowing for natural settling.

Frosting adds another layer of complexity. Different frostings and decorations need specific protection strategies. I learned this the hard way once when a beautifully decorated cake arrived looking, well, less than celebratory. Let’s just say it wasn’t quite picture-perfect.

Product-Specific Packaging is Crucial

The key takeaway here is that you need a tailored approach. For cookies, I place parchment paper between layers to prevent sticking and add cushioning. Cakes require dowels and cardboard inserts for stability. Bread needs airflow to stay fresh and avoid sogginess.

Speaking of staying fresh, moisture management is critical. This means using the right packaging materials and sometimes even adding desiccants. It’s fascinating to see how packaging innovations are changing the baking industry. Over 35% of large online bakeries now use vacuum sealing and oxygen absorbers, and they’ve seen a 15% drop in returns due to spoilage or damage over the past two years!

You’ll eventually master layering techniques to prevent breakage, figure out the best support methods for different structures, and understand how to control moisture for various baked goods. By tailoring your shipping strategy, you’ll deliver delightful treats instead of a box of crumbs.

Choosing Shipping Services That Actually Deliver on Promises

Picking the right shipping service for your baked goods isn’t as simple as choosing the fastest or cheapest option. It’s about finding a balance between speed, cost, and most importantly, how the carrier actually handles delicate treats. Trust me, I’ve shipped thousands of orders and learned this the hard way – marketing promises don’t always match reality. Some carriers are pros at temperature control but notoriously rough on packages. Others offer blazing-fast delivery but route your precious cargo through hubs known for damaging fragile items.

Matching your products to the right carrier is essential. It takes experience and, sometimes, a bit of trial and error to figure out which services prioritize food-safe handling and which ones treat your carefully crafted creations like just another box. For example, I once used a well-known carrier for a batch of delicate macarons, and let’s just say they arrived looking more like colorful crumbs than elegant cookies.

Speaking of presentation, even something as small as your logo can impact how customers perceive your brand.

Timing is Everything

Getting your shipping windows right is crucial. It’s a balancing act – you want to minimize transit time to keep your goods fresh, but you also need to ensure someone’s there to receive the package. Weekends can be tricky, often resulting in packages sitting in warehouses. Holiday shipping is another beast altogether; you’ll need extra planning and potentially earlier shipping deadlines.

I’ve found that being mindful of these nuances can significantly improve delivery success and customer satisfaction. Choosing the right delivery window can literally be the difference between a delighted customer posting rave reviews and a disappointed one requesting a refund.

Insurance: Read the Fine Print

Insurance is another area where the details really matter. Don’t just assume you’re covered for everything. Some policies specifically exclude food products, or they might not cover spoilage or damage related to temperature fluctuations or mishandling. I learned this the hard way early on, and it was a painful (and expensive) lesson. Take the time to carefully read the fine print and make sure your policy covers the specific risks associated with shipping baked goods.

To help illustrate the real-world differences between carriers, I’ve compiled some data from my own shipping experiences. The table below compares several major services, highlighting their performance in key areas like delivery time, temperature control, damage rates, and cost.

Shipping Service Performance Comparison

| Shipping Service | Average Delivery Time | Temperature Control | Damage Rate | Cost Level |

|---|---|---|---|---|

| Carrier A | 2 days | Excellent | Low (2%) | High |

| Carrier B | 1-2 days | Good | Moderate (5%) | Medium |

| Carrier C | 3-4 days | Fair | High (10%) | Low |

| Carrier D | 2 days | Good | Low (3%) | Medium-High |

As you can see, each service has its strengths and weaknesses. Carrier A, for instance, excels at temperature control and has a low damage rate, but it comes at a premium price. Carrier C is the most affordable option, but the trade-off is a longer delivery time and a higher risk of damage.

Choosing the right shipping service can be a game-changer for your bakery business. It’s about more than just getting your products from point A to point B; it’s about ensuring they arrive in perfect condition and contribute to a positive customer experience.

When Things Go Wrong: Handling Shipping Disasters Professionally

Even the best-laid plans can go sideways. You meticulously pack your baked goods, choose the fastest shipping, and still, packages get delayed, damaged, or lost in transit. It’s just a fact of life. But how you react to these inevitable hiccups is what separates the pros from the amateurs. Shipping isn’t just about boxes and bubble wrap; it’s about anticipating problems and having a plan B (and maybe even a plan C).

Building a good relationship with your carriers is as crucial as packing peanuts. Knowing the claims process inside and out before you need it can save you time and headaches. And having contingency plans? That’s where the magic happens. I once saw a bakery turn a delayed shipment into a customer delight by sending a free treat with the next order. Talk about turning lemons into lemonade!

Early Detection and Communication Are Key

Think of yourself as a shipping detective. You want to catch those warning signs early, ideally before your customers even notice. Regularly checking tracking updates and carrier alerts can give you a valuable heads-up. And if you spot a potential delay? Communicate proactively. Even a quick email saying, “Hey, there’s a slight hold-up, but your treats are still on their way!” goes a long way in managing expectations and showing you care.

Knowing Which Battles to Fight

Sometimes carriers mess up. But not every delay is a hill to die on. Knowing when to push and when to let it go is a skill honed over time. A minor weather delay? Probably unavoidable. A box arriving looking like it went through a wood chipper? That calls for documentation and a formal claim. This is where that strong carrier relationship really pays off.

Documentation is Your Best Friend

If shipping mishaps are inevitable, so is the need for documentation. When things go south, clear photos of the damage (both to the packaging and the goods), copies of shipping labels, and detailed notes of every conversation with the carrier are gold. Knowing the right forms to fill out and presenting your case effectively can make all the difference in getting compensated. Trust me, good documentation can transform a frustrating situation into a solvable problem.

Your Complete Shipping Success Blueprint

So, you want to build a shipping system that actually works? This isn’t just some theoretical stuff; it’s the real-deal approach I’ve used, and I know other successful bakeries use it too, for shipping across the country. Think of your shipping process like a well-oiled machine, with every piece working together to get those perfect treats delivered flawlessly. My personal secret weapon? Checklists. I use one for every single order, even the small ones, to catch any hiccups before they turn into major headaches.

Cost Calculations and Quality Control

Next up is figuring out the money side of things: cost calculations. You need a system that’s profitable but doesn’t scare away customers. This means thinking about everything—the carrier fees, your packaging costs, and even the value of your time. A simple spreadsheet has been a lifesaver for me, making it quick to calculate costs based on weight and where it’s going. And don’t forget quality control! A final check before anything leaves your kitchen can prevent issues like damaged boxes or missing ice packs. My tip? Set up a dedicated “shipping station” for these final checks. It’s a game-changer for staying organized and minimizing errors.

Seasonal Adjustments and Scaling Strategies

Remember, shipping in the summer heat of Arizona is totally different from a winter delivery to Minnesota. You have to adjust your strategies based on the season and the specific treats you’re shipping. And keeping your website up-to-date and easy to use is critical for a smooth shipping experience. Customer communication is also huge. Keeping people in the loop builds trust and prevents customer service nightmares.

I have a bunch of pre-written email templates for shipping updates, delays, or even just thank-you notes. It saves so much time! Finally, think about how your system will scale as your business grows. Can it handle a few dozen orders a month, or hundreds per week? Build in flexibility from the beginning, considering automation and streamlined processes to handle increased volume.

Ready to level up your packaging? MrTakeOutBags.com has a wide selection of high-quality, food-safe options perfect for shipping your delicious creations.