Understanding What Makes Compostable Containers Actually Work

The word “compostable” is everywhere these days. But if you’re a restaurant owner, you need compostable to go containers that truly decompose, not just ones with a greenwashed image. I’ve been chatting with restaurant owners who’ve already made the switch, and the main takeaway? Performance is everything. A container might look perfect in a picture, but can it handle a busy Friday night and a steaming order of Pad Thai?

There’s a whole confusing world of compostable certifications out there. Don’t just take a company at their word. Look for reliable certifications, like from the BPI (Biodegradable Products Institute). These certifications show that the containers have passed strict testing and are proven to break down under specific composting conditions. This is super important because home composting and industrial composting are very different environments.

Not all compostable materials are equal. Some hold up well under heat, while others get soggy and fall apart. I know a restaurant owner who switched to bagasse containers for soup, only to find they dissolved before the customer even got home! He learned the hard way that material choice is crucial.

Speaking of growth, the global compostable packaging market is projected to hit $100.44 billion by 2025, with a CAGR of 8.5%. This shows that consumers are more aware of eco-friendly options, and regulations around plastic waste are getting stricter. Choosing the right compostable containers isn’t just good for the planet; it’s good for business. So, how do you pick the best option for your restaurant? We’ll dive into that next.

Navigating Materials and Finding Your Perfect Match

Not all compostable to-go containers are created equal. The material you choose impacts everything from how happy your customers are to your restaurant’s bottom line. Let’s break down the usual suspects: PLA (polylactic acid), bagasse (sugarcane fiber), molded fiber, and wheat straw. Each has its pros and cons.

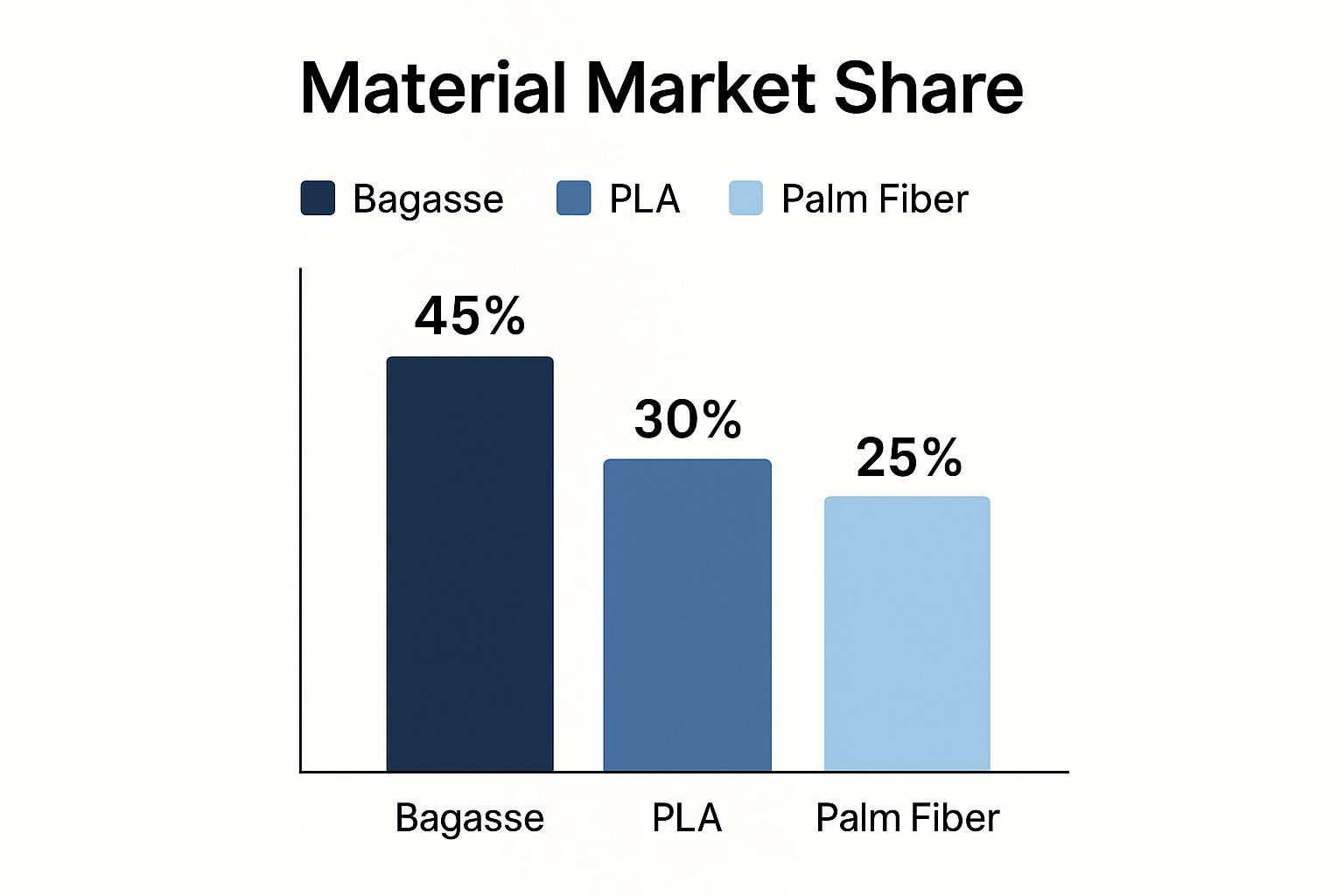

This chart shows the market share for different compostable container materials, focusing on bagasse, PLA, and palm fiber. Bagasse takes a hefty 45% slice of the pie, followed by PLA at 30% and palm fiber with 25%. This tells us bagasse is pretty popular right now, probably because it’s affordable and readily available. But remember, just because it’s popular doesn’t mean it’s the right fit for your restaurant.

Matching Materials to Your Menu

PLA, a plant-based plastic, is fantastic for cold dishes like salads. However, I’ve personally seen it warp under the heat of hot food. I talked to a restaurant owner who switched from PLA to bagasse for their hot noodle dishes and saw a huge improvement in customer satisfaction. Bagasse is generally sturdy, but it can absorb liquids after a while. So, it’s better suited for drier foods. Molded fiber, made from recycled paper, is a great insulator but can be pricier.

For instance, if your menu is mostly fried food, molded fiber might be your best bet because of its grease resistance. But if you’re serving soups and stews, you’ll need a liquid-resistant lining, no matter what material the container is made of. Consider your average order—how hot is it, what’s the consistency like, and how long will it travel? These are the questions that should guide your material choices.

To help you compare, I’ve put together this handy table:

Compostable Container Materials Comparison

| Material | Heat Resistance | Durability | Cost Range | Best For | Composting Time |

|---|---|---|---|---|---|

| PLA | Low | Moderate | Low-Medium | Cold foods, salads | 6-12 months |

| Bagasse | Medium | Moderate | Low | Drier foods, hot entrees (short term) | 3-6 months |

| Molded Fiber | High | High | Medium-High | Fried foods, hot and greasy items | 3-6 months |

| Wheat Straw | Medium | Moderate | Medium | Hot and cold foods | 3-6 months |

As you can see, each material brings something different to the table. Choosing the right one really depends on your specific needs.

Considering Cost and Sourcing

Of course, cost is a big consideration. Bagasse is usually the most budget-friendly, while molded fiber tends to be the most expensive. Wheat straw lands somewhere in the middle. Reliable sourcing is another crucial factor. I’ve seen supply chain issues leave restaurants scrambling for containers. It’s smart to build relationships with several suppliers to navigate these challenges. Don’t hesitate to test different materials and suppliers with smaller orders before committing to bulk purchases. Finding the right compostable to-go container takes time, but it’s a worthwhile investment for your business and the environment.

Making The Business Case Beyond Just Being Green

Switching to compostable to-go containers isn’t just about feeling good. It’s good business. Let’s ditch the warm fuzzies for a minute and talk about the real financial impact – the hidden costs and unexpected perks that often get overlooked. I’ve personally seen how this seemingly small change can affect everything from storage space to customer loyalty.

Beyond the Initial Investment

Sure, compostable containers might have a higher upfront cost than traditional options. But have you really dug into the potential long-term savings? Think about it: lower waste disposal bills, a shiny new brand image, and customers coming back for more. These all add up. I talked to a restaurant owner recently who actually saw a decrease in their overall expenses after making the switch. They managed to negotiate a better deal with their waste hauler because of the reduced volume. Plus, they saw a big jump in repeat customers who appreciated their eco-friendly approach.

Communicating Value to Customers

Budget-minded customers might initially raise an eyebrow at any perceived price increase. But there are clever ways to frame the switch positively. Instead of dwelling on the added cost, spotlight the value of compostable containers. Talk about your commitment to the environment and the positive impact it has on the local community.

You could even offer a small discount for customers who bring their used containers back for composting. This creates a closed-loop system and further trims your costs. It also strengthens your sustainable practices and builds a sense of community around your brand.

Speaking of market trends, North America is leading the way in adopting compostable to-go containers. This market is projected to grow at a 10.5% compound annual growth rate (CAGR), fueled by policies to reduce plastic waste and the growing wave of green consumerism. This shows that using compostable packaging positions your restaurant as a forward-thinking leader.

Leveraging Sustainability for Competitive Advantage

In a sea of restaurants, sustainability can be what makes you stand out. It attracts environmentally conscious customers and gives you something unique to offer. Promote your compostable containers on your menu, website, and social media. Share your sustainability story and teach customers about the benefits.

I know a restaurant that teamed up with a local composting facility and advertised its partnership everywhere. The result? A surge of positive online reviews and media attention, which is basically free advertising gold. This proves sustainability can be a win-win, helping both your business and the planet. By thinking through these points, you can build a successful and sustainable business model for the future.

Smart Sourcing and Building Supplier Relationships That Last

Finding the right supplier for your compostable to-go containers is a big deal. It’s not just about the lowest price; it’s about finding a reliable partner who delivers quality and shares your commitment to sustainability. Trust me, I’ve seen how a bad supplier can completely throw off a restaurant’s rhythm. Let’s talk about finding partners you can actually rely on.

Identifying Trustworthy Suppliers

Look beyond the initial sales pitch. Ask for references from other restaurants. Find out about their track record: Do they consistently meet deadlines? What’s their quality control process like? And, importantly, how do they handle problems? Getting these questions answered upfront can save you a lot of headaches later.

Dig deep into their certifications. Are their compostable to-go containers really certified by reputable organizations? This confirms they meet industry standards and will actually break down as advertised. A quick online search can also tell you a lot. Read reviews and testimonials to see what other customers are saying.

Negotiating and Managing Orders

Minimum order quantities (MOQs) can be tough, especially for smaller restaurants. Don’t be afraid to negotiate. A good supplier will be willing to work with you, especially when you’re just getting started. Also, for restaurants, local visibility is everything. Optimizing your online presence is crucial, and you can find great tips on Local SEO for Restaurants. This can even help you connect with potential suppliers in your area.

A solid supplier relationship is your best defense against supply chain disruptions. Open communication is key. Keep them in the loop about your needs and be honest about any potential challenges you foresee. A good supplier will be a problem-solver, not a problem-creator.

Building Backup Plans

Having a backup supplier is like having an insurance policy. It’s there to protect you in case your primary supplier falls through. This ensures you always have a source for your compostable containers, even if your main supplier runs into a shortage. This might mean slightly higher costs sometimes, but the peace of mind is worth it. Testing new suppliers with small orders before going all-in is a smart move. This lets you check out their product quality and reliability without a huge risk.

Implementation Without Overwhelming Your Operations

Switching to compostable to-go containers doesn’t have to turn your operations upside down. I’ve helped restaurants navigate this transition smoothly, and they kept their cool (and their service quality) throughout the process. The secret? A well-planned, phased approach. Let me share some insights from the trenches.

Optimizing Storage for Bulkier Containers

One common hiccup is storage. Compostable containers can sometimes be bulkier than their traditional counterparts, which can be a pain if your storage space is already tight. Think vertical! Stackable shelves and wall-mounted racks are your best friends here. They can free up a surprising amount of floor space. I remember working with a small cafe crammed into a tiny space – vertical shelving was a game changer. They couldn’t believe how much more they could fit. Another tip: consider a just-in-time inventory system. Order smaller quantities more frequently. It’ll mean less to store at any given time.

Training Your Staff for Success

Your staff are on the front lines, so they need to be comfortable with the new containers. Forget lengthy, boring lectures. Short, hands-on training sessions are way more effective. Focus on the practical stuff: how to fill the containers properly, which lids fit which containers, and how to chat with customers about the benefits. A quick quiz afterwards helps reinforce everything. And don’t forget the importance of strong supplier relationships!

Communicating with Your Customers

Be upfront with your customers. Tell them why you’re switching to compostable containers. Explain the environmental benefits and how to dispose of them properly. Simple signage at the counter and a quick note on your menu can work wonders. I once saw a restaurant create a fun infographic for their social media about the composting process. It was a hit!

Handling Hiccups and Maintaining Consistency

There will be bumps along the way. A delayed shipment, a new employee who missed training – these things happen. Have a backup plan. Keeping a small reserve of traditional containers on hand can be a lifesaver. Check in with your staff regularly to address any concerns and tweak things as you go. That constant feedback loop is essential. And remember to celebrate the wins! Acknowledging your team’s efforts and marking milestones makes a huge difference. It reinforces the importance of the change and keeps everyone positive.

To help you visualize the process, I’ve put together a handy timeline and checklist:

Implementation Timeline and Checklist

| Timeline | Action Items | Staff Training | Customer Communication | Success Metrics |

|---|---|---|---|---|

| Week 1 | Order initial supply of compostable containers and lids. | Initial training session on new containers. | Announce switch to compostable containers on social media. | Track inventory levels of new containers. |

| Week 2 | Implement new containers for front-of-house operations. | Follow-up training and Q&A with staff. | Place signage at the counter explaining the composting process. | Monitor customer feedback through online reviews. |

| Week 3 | Assess storage solutions and adjust as needed. | Quiz staff on proper handling procedures. | Add composting instructions to receipts/menus. | Measure the reduction in traditional container waste. |

| Week 4 | Fully transition to compostable containers. | Ongoing feedback and support for staff. | Share customer testimonials about sustainability efforts. | Analyze cost savings from switching containers. |

This table gives you a week-by-week view of key tasks, training, communication strategies, and how to measure your progress. Remember, this is just a sample – you can adjust it to fit your specific needs.

By thinking through these practical details, you can make the switch to compostable containers smoothly and efficiently. Your staff will be on board, your customers will appreciate it, and the planet will thank you.

Future-Proofing Your Packaging Strategy

The world of compostable to-go containers is constantly evolving. Savvy restaurant owners are looking ahead, anticipating trends in sustainable packaging, potential regulations, and how technology might reshape the industry.

Adapting to the Evolving Landscape

Flexibility is the name of the game when it comes to your packaging strategy. The market for compostable packaging is exploding. It’s expected to hit $132.86 billion by 2032, with a 6.51% CAGR from 2025. That kind of growth, driven by new biodegradable materials, investments in circular economy initiatives, and better composting infrastructure, tells us something: compostable packaging is here to stay.

So how do you stay ahead of the curve? Staying informed is a great start. Subscribe to industry newsletters, catch a few webinars, and follow relevant organizations on social media. Don’t feel like you need to absorb everything, though. Just focus on the developments that truly impact your business.

Embracing Technological Advancements

Technology is changing everything, and packaging is no exception. Think about how customers might interact with your packaging beyond simply tossing it in the compost bin. Imagine scanning a QR code to learn about the materials’ origins and proper disposal.

What about smart labels that track composting progress? Or biodegradable sensors that monitor food freshness? These innovations could completely change how we handle food waste and packaging disposal.

Building a Sustainable Future

Smart choices today will benefit your restaurant down the line. Choosing the right compostable to-go containers is a big piece of the puzzle. It’s an investment in your business, your community, and the planet. Plus, it shows your customers you’re not just focused on the bottom line.

Ready to find some high-quality, eco-friendly takeout packaging options that fit your restaurant’s needs? Check out MrTakeOutBags.com and see how they can help you strengthen your brand and minimize your environmental footprint.