Understanding The Food Packaging Supplies Landscape

The way we think about food packaging supplies is always changing. For businesses to stay ahead, they need to adjust how they approach packaging. It’s not just about basic containers anymore; it’s about finding options that connect with today’s shoppers and solve real industry problems.

Key Drivers Shaping The Market

Several big factors are guiding where the food packaging supplies industry is headed. What shoppers want, especially convenience and a strong focus on food safety, is a major influence.

People are looking for packaging that suits their on-the-go lives. This means things like easy-to-open containers, single-serving sizes, and items that are simple to carry, all while keeping the food fresh and safe. On top of this, strict rules about materials that touch food and how products are labeled also play a big part in packaging decisions.

All these elements together are causing the market to grow significantly. Just look at the global food packaging market: it was valued at around USD 398.5 billion in 2024 and is expected to hit roughly USD 421.6 billion by 2025.

Looking further ahead, predictions suggest it could expand to about USD 718.29 billion by 2034. That’s a compound annual growth rate (CAGR) of 6.06% from 2025 to 2034, which highlights how active this area is.

The Evolving Role of Packaging

This market growth points to a big change in how companies see food packaging supplies. It’s moved beyond simply holding food; packaging now actively boosts a product’s appeal.

Modern packaging is often created to make products last longer on the shelf, which helps cut down on food waste. It’s also a great way for brands to tell their story and share their values with customers.

Think about it: creative packaging can make an item catch a shopper’s eye on a busy shelf, almost like a silent salesperson. Top companies are also using new technologies to get past old packaging problems, like making materials better at protecting food or adding smart elements. These efforts help build more solid relationships with customers.

Strategic Navigation For Businesses

For businesses to do well, they need to actively look for new opportunities in the food packaging supplies field. This means getting a handle on how markets differ from place to place, because what shoppers like and the rules in place can change a lot depending on the region.

Staying up-to-date with these local differences helps companies adjust their packaging to fit just right.

Keeping an eye on industry developments, like the move towards sustainable materials or the rise of smart packaging technologies, lets businesses place themselves smartly for what’s next. This kind of forward-thinking is key for choosing food packaging supplies that don’t just work for now but also get ready for what the market might look like down the road. The main takeaway is that understanding these trends is vital for making smart choices in a competitive space.

Choosing The Right Food Packaging Supplies For Your Business

Picking the right food packaging supplies isn’t just about boxing up your food; it’s a key step in keeping products safe, customers happy, and costs in check. When you understand your options, you can find solutions that truly fit your business needs without breaking the bank. This approach helps ensure your packaging does more than just hold food—it actively supports your product from your kitchen to the customer.

Decoding Packaging Categories

The variety of food packaging supplies available might seem overwhelming at first, but it becomes clearer when you group them into practical types. For instance, flexible packaging, which includes items like films and pouches, is great for conforming to different product shapes and can be very economical with space and materials. Good examples are bags for coffee beans or pouches for snacks.

Conversely, rigid containers—think plastic tubs, glass jars, or strong boxes—provide top-notch protection for items that are delicate or need a more defined shape for presentation. Knowing the different types of packaging out there is key to making smart choices in the food packaging supplies market.

Understanding Packaging Layers

It’s also really important to know the difference between packaging layers, as each one has a specific job:

- Primary packaging is the layer that directly touches the food. Its main role is to keep the product safe and fresh. Think of the plastic wrap on a sandwich or the bottle that holds your drink.

- Secondary packaging is used to bundle groups of primary packaged items. This could be a cardboard box holding several cereal bars or the plastic rings connecting a six-pack of soda cans. It helps with easier handling and branding.

- Tertiary packaging is what businesses use for shipping and handling large quantities, like pallets wrapped in stretch film. This layer makes sure products arrive at their destination undamaged.

To help you sort through the options, here’s a guide comparing different packaging types:

Food Packaging Supplies Comparison Guide

Comprehensive comparison of different packaging types, their materials, applications, and key benefits

| Packaging Type | Primary Materials | Best Applications | Key Benefits | Considerations |

|---|---|---|---|---|

| Plastic Containers | PET, PP, PS | Takeout meals, deli items, salads, sauces, desserts | Good visibility, durable, often resealable, moisture-resistant | Recycling availability varies, fossil fuel-based, potential for breakage |

| Paperboard Boxes | Coated/Uncoated paperboard, Kraft paper | Bakery goods, pizza, dry foods, and some takeout | Often recyclable/compostable, good for printing, lightweight | May need coating for grease/moisture, can crush easily |

| Flexible Pouches | Plastic laminates, foil, sometimes paper | Snacks, coffee, liquid products, single-serve items | Lightweight, space-efficient, good barrier properties | Often difficult to recycle (multi-material), may require sealing equipment |

| Glass Jars/Bottles | Glass | Jams, preserves, sauces, beverages, and premium items | Inert, excellent barrier, reusable, 100% recyclable, premium feel | Heavy, fragile, higher cost, higher transport footprint |

| Compostable Options | PLA, bagasse, bamboo, molded fiber | Takeout containers, plates, bowls, cutlery | Biodegradable (industrial), made from renewable resources | May have a shorter shelf life, specific composting needs, and often pricier |

This table should give you a clearer picture of how different materials and formats stack up, helping you choose what’s best for your specific food products and business goals. Making the right choice involves balancing protection, presentation, and practicality.

Material Matters: Performance, Compatibility, And Cost

The materials in your food packaging supplies play a huge role in how well they work, whether they’re safe with your food, and how much they cost. For example, some plastics are great at keeping moisture out, while certain paper-based materials are popular for being eco-friendly. Compatibility is crucial; acidic foods, for instance, can react badly with some materials, which might change the taste or even the safety of the food.

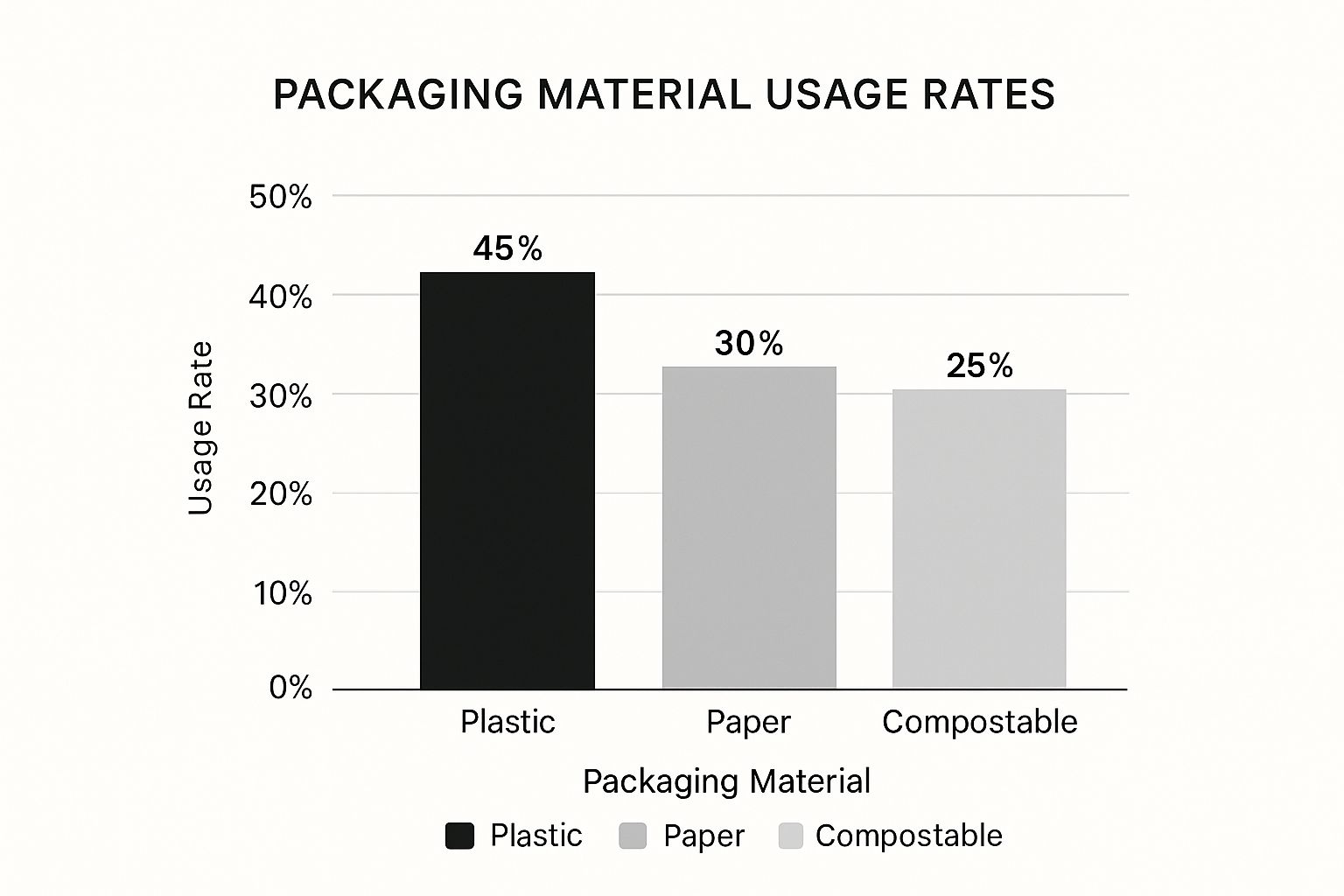

To give you an idea of what materials are commonly used, the chart below shows typical usage rates for major food packaging supplies.

This image shows that plastic is still widely used (45%), but it also points out that paper (30%) and compostable options (25%) are significant parts of the market. Juggling these material properties with your budget is key. For instance, when you’re looking at disposable food containers, material safety and cost are very important. Setting up a way to weigh these factors will help your business thrive in the long run.

Building Your Sustainable Food Packaging Supplies Strategy

Choosing sustainable food packaging supplies isn’t just about being green; it’s a smart business decision that can affect how your company runs and its bottom line. Real sustainability in packaging goes further than catchy phrases. It means finding real-world solutions that bring actual advantages while keeping your products safe and sound.

This means looking into different kinds of materials. You’ve got biodegradable options that break down on their own, recyclable materials made to be used again, and compostable alternatives that can go back into the soil as nutrients.

The move towards sustainability is a big deal in the food packaging supplies field; it’s shaping the industry. The worldwide market for sustainable packaging, filled with these eco-friendlier materials, is expected to grow quite a bit between 2025 and 2035.

What’s driving this growth? Mostly, it’s new rules pushing to reduce plastic waste and environmental damage, plus more shoppers wanting packaging that’s kind to the planet. Making these changes often involves thinking about new materials from renewable sources and using circular economy principles to cut down on waste.

Key Pillars Of A Sustainable Packaging Program

Switching to sustainable food packaging supplies takes some thought and good old-fashioned elbow grease. Here are a few practical steps to help you make the change:

- Supplier Collaboration: Team up with suppliers who know their sustainable packaging. They can be a huge help in finding materials that fit your green goals and work well for your products.

- Consumer Engagement: Let your customers know about your eco-friendly packaging and how to dispose of it correctly. This can make them feel more connected to your brand and encourage good habits.

- Regulatory Awareness: Keep an eye on current and new environmental rules. This is key for staying on the right side of the law and showing your business is a responsible player.

Navigating The Transition Effectively

To make a sustainable packaging program work, you also need to be upfront about the cost implications, any possible performance trade-offs, and what realistic timeline considerations might be.

For example, a compostable container sounds great, but you’ll want to double-check how it holds up with hot or oily foods. It’s also worth looking into other ways to improve your food and beverage operations, like using tech to better connect with customers. For instance, understanding how features like QR Codes and Payment Links can be used with your food and beverage store on a platform like Shopify could open up new possibilities.

Ultimately, the goal is to find a balance where your packaging choices support both the planet and your business needs. This way, your decisions about food packaging supplies are both environmentally sound and sensible for your operations.

Exploring Global Food Packaging Supplies Opportunities

Thinking about taking your food packaging supplies business beyond your home turf? It’s a smart move for growing companies. The global market isn’t a one-size-fits-all deal; it’s more like a vibrant collection of different needs and exciting chances. To succeed, you’ll need to get to know these international differences and adjust your game plan.

Understanding Regional Nuances in Packaging Demands

What sells well for food packaging supplies in one corner of the world might completely miss the mark in another. A few key things create these unique regional needs. For example, cultural preferences are a big deal, affecting everything from how big a package should be and what it looks like, to the kinds of convenience features people value.

Then there are economic conditions. These affect how much people can spend and what they prioritize. In some places, keeping costs low is the most important thing. In others, shoppers might happily spend more for cool new designs or packaging that’s good for the planet. And don’t forget about regulatory environments! Laws about materials that touch food, what needs to be on the label, and how to handle waste can be very different from country to country, directly influencing your choices for food packaging supplies.

Spotlight On High-Growth Regions

While well-known markets like North America and Europe are still players, a lot of the big growth in food packaging supplies is happening in developing economies. These areas offer fresh opportunities thanks to more people moving to cities, having more money to spend, and changing lifestyles. A fantastic example of this kind of boom is the Asia Pacific region.

This part of the world has become a real giant in the food packaging supplies market. In 2024, it was valued at an impressive USD 152.3 billion. And it’s not stopping there – predictions show it rocketing to USD 282.22 billion by 2034, which is a compound annual growth rate (CAGR) of 6.36%. This incredible growth, making up about 38% of the total market value, is powered by people earning more, growing populations, and strong demand in countries like China, India, and Japan. These numbers highlight the huge potential for businesses ready to look internationally.

Strategic Approaches To International Expansion

Taking your food packaging supplies business global successfully means you need a solid plan and good follow-through. Here are some key strategies:

- Local Sourcing Strategies: Think about finding materials or even complete packaging closer to your new market. This can cut down on shipping costs and time. It might also help you fit in better with local tastes and support the local economy.

- Distribution Considerations: Getting your distribution considerations right is essential. This means figuring out the local shipping networks, import and export rules, and where to store your goods so your food packaging supplies get to customers smoothly.

- Partnership Opportunities: Teaming up for partnership opportunities with local distributors, manufacturers, or people who really know the market can give you amazing insights and open doors. These kinds of collaborations can make it easier to handle cultural differences and tricky regulations.

By thinking carefully about these regional details and how you’ll approach them, businesses can find some serious growth in the global food packaging supplies market. Adapting your approach to fit what different markets need is the real secret to managing risks and making the most of going international.

Smart Technology In Food Packaging Supplies

The field of food packaging supplies is rapidly moving past the idea of mere containers. Smart packaging is introducing new ways to add value, going beyond just protecting and keeping food fresh. These developments are changing the way businesses and consumers look at and use packaging.

Actionable Insights Through Intelligent Packaging

Picture food packaging supplies that can inform you whether a product remains fresh or if it has been stored incorrectly. This is now achievable through the use of sensors and indicators. These components can keep track of several conditions, including:

- Freshness levels of the product

- Temperature changes during shipping and storage

- Handling practices throughout the supply chain

This means businesses and consumers can receive clear, usable information instead of relying on guesswork. For instance, an indicator on a meat package that changes color could plainly show if the item was exposed to unsafe temperatures, marking a big step forward in managing food safety.

Innovations Enhancing Safety And Engagement

The advancements continue beyond just monitoring. Active packaging systems are made to interact with the food itself, perhaps by removing oxygen to prolong shelf life or by releasing substances that fight microbes. Similarly, antimicrobial coatings built into food packaging supplies provide another safeguard against spoilage and harmful organisms.

Moreover, smart labels are making packaging an interactive tool. With a quick scan, these labels can offer consumers extensive product details, cooking suggestions, or even augmented reality features. The growing adoption of intelligent packaging, such as smart labels and active packaging that monitors freshness, is helping the market expand. Also, the boom in e-commerce food delivery and strict food safety rules have pushed the need for inventive and secure packaging solutions globally.

Practical Benefits And Implementation

Using these smart technologies in food packaging supplies brings real advantages. Companies can differentiate their products in a competitive market, improve customer satisfaction by being more transparent and offering better quality products, and significantly reduce food waste through better shelf life management. Importantly, these systems strengthen food safety protocols, a top priority in the industry. For businesses worried about keeping products safe, especially during delivery, understanding different protective methods is vital.

Although the initial cost of smart packaging might be a point to consider, a thorough cost-benefit analysis often shows long-term savings and increased customer loyalty. The main takeaway is that incorporating smart technology into food packaging supplies is becoming a key approach for businesses aiming to boost efficiency, safety, and how they connect with customers.

Mastering Food Packaging Supplies Sourcing, and Supplier Relationships

Finding reliable sources for your food packaging supplies is much more than just making a purchase; it’s about building partnerships that strengthen your business for the long haul. When you shift from simple transactions to more collaborative relationships with suppliers, you can see a real difference in your operational flow and the quality of your products. This thoughtful approach ensures your packaging does more than meet basic requirements—it helps your business grow.

Identifying And Evaluating Potential Suppliers

The path to a solid supplier relationship kicks off with thorough due diligence. When you’re looking for food packaging supplies, it’s important to see beyond the price. You need to check out a potential supplier’s overall capability and how dependable they are. This involves looking into their history, how much they can produce, and if they stick to industry standards.

Setting up clear quality assurance protocols right from the start is also crucial. For instance, knowing how a supplier ensures consistent materials and prevents defects can save you a lot of trouble later. Think about asking about their internal quality checks and any third-party certifications they have, as these are good signs of their dedication to quality in food packaging supplies.

To assess potential partners for your food packaging supplies in an organized way, it’s helpful to use a structured method. Here’s a look at how you can evaluate them effectively.

Supplier Evaluation Criteria Matrix

Key factors and scoring criteria for evaluating food packaging suppliers

| Evaluation Criteria | Weight (%) | Assessment Method | Minimum Score | Key Questions |

|---|---|---|---|---|

| Quality & Consistency | 30% | Review certifications (e.g., ISO, FDA-approved materials), material spec sheets, sample testing, and factory audit reports. | 4 out of 5 | “What are your documented defect rates?” “Can you provide current material safety data sheets and relevant certifications?” “May we conduct a site visit?” |

| Reliability & Lead Time | 25% | Check on-time delivery records, inventory management systems, and communication protocols for delays. | 4 out of 5 | “What is your average on-time delivery percentage?” “How do you manage unexpected production surges or delays?” “What is your standard lead time?” |

| Cost & Overall Value | 20% | Analyze pricing structures, payment terms, potential for volume discounts, and total cost of ownership. | 3 out of 5 | “Can you provide a detailed cost breakdown?” “What are your payment terms?” “Are there opportunities for cost savings with larger orders?” |

| Service & Support | 15% | Evaluate responsiveness, availability of technical support, and problem-solving effectiveness. | 4 out of 5 | “What is your typical response time for inquiries?” “Who is our dedicated contact person?” “How do you handle product issues or complaints?” |

| Sustainability Focus | 10% | Assess the availability of eco-friendly materials, ethical sourcing practices, and transparency in sustainability efforts. | 3 out of 5 | “What sustainable packaging options do you offer?” “Can you share your company’s sustainability policy or report?” “How do you ensure ethical sourcing?” |

Using such a matrix allows for a consistent and fair comparison across different suppliers. It helps ensure that all critical aspects are considered before making a commitment, leading to more robust partnerships for your food packaging supplies.

Building And Managing Strong Supplier Partnerships

After you’ve picked your suppliers, the next step is to cultivate these relationships. Effective contract negotiation is essential, aiming for deals that fairly balance cost with the quality and service levels your food packaging supplies demand. This isn’t just about getting the lowest price; it’s about agreeing on terms that foster a mutually beneficial, long-term relationship.

Moreover, managing supplier performance with measurable metrics is vital for ongoing improvement. Regularly tracking key performance indicators (KPIs) such as on-time delivery rates (aiming for above 95% is a good benchmark), defect percentages, and responsiveness helps uphold standards and pinpoint areas for joint development. For example, if defect rates for your food packaging supplies start to rise, working with the supplier to find the root cause is more productive than just finding a new one.

Putting risk management strategies in place is also key to shielding your business from supply chain disruptions, which can seriously affect your ability to deliver products. This could involve qualifying backup suppliers or understanding your main supplier’s backup plans. Ultimately, building collaborative relationships, where open communication and joint problem-solving are standard, turns suppliers into genuine partners. These strong partnerships in food packaging supplies are vital for adapting to market shifts and ensuring your sourcing choices align with your larger business goals and operational needs.

Key Takeaways

Getting your food packaging supplies right isn’t just about luck; it takes a solid plan and steady work. Think of this as your straightforward guide to turning good ideas into real actions you can start using now. We’re here to help you make smart packaging choices that truly help your business’s aims.

Actionable Strategies For Immediate Impact

To see real improvements with your food packaging supplies, it’s smart to pick your battles. Don’t try to change everything overnight. Instead, zero in on adjustments that offer the best results, like saving money, better protecting your products, or making customers happier. For instance, a simple switch to a better-fitting container can cut down on material use and shipping expenses.

Here’s a simple checklist to guide you toward those important areas:

- What’s Not Working?: Figure out where you’re having trouble – maybe it’s damaged goods, high packaging expenses, or unhappy customer comments about your packaging.

- Easy Fixes First: Can you spot any simple tweaks, like a different way to seal packages or a small change in materials, that could help right away?

- Match Your Brand: Does your packaging show what your brand stands for, such as a focus on being eco-friendly or delivering top quality? Make changes that highlight these values.

- Weigh the Costs and Gains: Look at what you’ll need to spend versus what you expect to gain from any packaging update.

Realistic Implementation Guidance

After you know what your top priorities are for food packaging supplies, map out a sensible schedule with clear goals. Rushing big changes can mess up your daily work and cause mistakes. Often, a phased approach is the most effective, giving your team time to get used to new things and fix any problems that pop up.

A frequent oversight is not spending enough time testing new food packaging supplies. Make sure you thoroughly check out new materials or designs in actual use before you switch over completely. This step is key to preventing expensive product returns or harm to your brand’s image.

Consider these milestones for your implementation plan:

- Phase 1: Research & Supplier Checks (1-2 Months): Decide on your materials, and find and approve new suppliers.

- Phase 2: Trial Run (1 Month): Try out the new packaging with a small batch of products. Collect thoughts from your team and, if you can, from a few customers.

- Phase 3: Gradual Rollout (2-3 Months): Start using the new packaging more widely across your product lines, keeping a close eye on how it’s working.

- Phase 4: Check and Adjust (Ongoing): Keep an eye on the results and tweak things as you go.

Building Internal Excellence In Packaging

Achieving lasting success with your food packaging supplies comes from developing solid skills within your own company. This involves assigning specific people or groups to manage packaging choices, work with suppliers, and maintain quality. Empowering your team with the necessary information and tools is vital.

Handling the adjustments that new packaging plans bring is also a big part of the process. Talk openly with everyone involved—from purchasing and marketing to the production floor—explaining the reasons for the changes and their specific responsibilities. Well-planned training can help make sure everyone is comfortable with new procedures or how to handle different materials.

To build up this in-house know-how:

- Form a Packaging Team: Get people from various departments to work together on packaging projects.

- Support Learning: Offer regular training on new materials, packing methods, and what’s current in sustainable food packaging supplies.

- Centralize Information: Make a go-to place for all your packaging details, supplier contacts, and helpful tips.

Ensuring Consistent Quality And Continuous Improvement

Keeping your food packaging supplies up to par means having solid quality control procedures in place. These aren’t just hoops to jump through for inspections; they’re essential for safeguarding your products and your brand’s reputation. This means having clear guidelines for the materials you receive and checking them regularly as you package your goods. For instance, write down standard ways of doing things (SOPs) for setting up machinery, handling materials, and inspecting finished packages.

It’s also a good idea to set up performance monitoring systems to keep an eye on important numbers related to your food packaging supplies. This information can show you where you can make your approach even better. Are fewer items getting damaged? Are you hitting your goals for saving money? Looking at this data regularly helps you make smart choices and keep getting better.

Important elements for maintaining quality and making improvements are:

- Written Standards: Have clear, written rules for all your food packaging supplies.

- Checking New Materials: Set up ways to make sure the supplies you get are what you ordered.

- Mid-Process Inspections: Check things during the packaging process to spot any problems quickly.

- Gathering Feedback: Create ways to collect and use comments about packaging from your team, customers, and suppliers.

By using these approaches consistently, your business can truly master its packaging. Ready to find the perfect food packaging supplies for your business and implement these strategies with expert support? Explore our extensive range of high-quality takeout packaging solutions and benefit from personalized service when you visit MrTakeOutBags.com for a wide range of solutions today to elevate your packaging!

Comments are closed.