Why Custom Restaurant Packaging Transforms Brand Experience

Custom restaurant packaging is more than just a container. It’s a powerful tool that elevates your brand experience, acting as a silent ambassador communicating your values with every order. Investing in high-quality, custom packaging can differentiate your restaurant in a competitive market and leave a lasting impression.

Packaging and Perceived Value

A beautifully packaged item is instantly perceived as higher quality, even before the product is experienced. This psychological principle applies directly to restaurant packaging. Customers often associate thoughtful packaging with higher-quality food and are willing to pay a premium. A sleek box for sushi, for example, conveys elegance, while a rustic paper bag for burgers suggests fresh ingredients.

The Unboxing Experience and Social Media

Memorable unboxing experiences generate significant buzz on social media platforms like Instagram and TikTok. Customers love sharing visually appealing packaging, creating organic marketing that expands your reach and attracts new customers.

Sustainability and Customization

Sustainability and customization are important trends in restaurant packaging. Demand for recyclable materials is rising as businesses aim to reduce their environmental impact. This shift towards eco-friendly practices not only benefits the planet but also enhances brand perception. Furthermore, customized packaging allows restaurants to express their unique brand identity, strengthening customer loyalty and recognition. This allows restaurants to attract environmentally conscious consumers while reinforcing their brand.

Building Emotional Connections

Custom packaging builds stronger emotional connections with customers. A handwritten note, a personalized message, or a loyalty sticker creates a sense of personal appreciation. These small gestures foster loyalty and encourage repeat business. Custom packaging isn’t just a functional necessity; it’s a strategic investment that transforms your brand experience and drives growth.

Market Growth Opportunities In Custom Packaging Investment

The custom packaging industry offers exciting opportunities for restaurants looking to make smart investments. Changing consumer desires for personalized experiences, combined with advancements in technologies like digital printing, are driving this shift. These technologies make highly customized and sustainable packaging solutions a reality. Forward-thinking restaurant owners are already capitalizing on this trend, aiming to harness the growth potential before the market becomes too competitive.

Identifying High-Growth Segments in Custom Packaging

This growth provides a significant opportunity for restaurants of all sizes, from independent food trucks to major chains. Smaller restaurants, for example, can utilize custom packaging to build a distinctive brand identity. Larger chains, on the other hand, can leverage it to maintain brand consistency across numerous locations. Using custom packaging to set your business apart might also help. This expanding market presents various entry points, allowing restaurants to find the ideal solution for their specific needs and budget.

The custom packaging sector, including restaurant packaging, has experienced impressive growth. The global market was valued at $43.88 billion in 2023. Projections estimate it will reach $71.10 billion by 2032, expanding at a CAGR of 5.62%. Advancements in digital printing are a key driver, enabling more personalized and eco-friendly options. Custom packaging provides benefits for restaurants, such as enhancing brand image and offering better product protection.

The increasing focus on sustainability further strengthens the position of custom packaging as an environmentally conscious option, which will likely contribute to ongoing growth in the sector.

Budgeting and Supplier Landscapes

Successfully entering this market requires careful planning and a thorough understanding of the industry. Restaurants should establish clear budgets for their custom packaging projects. Thoroughly researching and selecting the right packaging suppliers is also critical. Understanding supplier capabilities and pricing is crucial for maximizing your investment. Effective budgeting guarantees that custom packaging aligns with the overall business goals and available financial resources.

Calculating Long-Term ROI

It’s essential to look beyond the initial costs and consider the long-term benefits of custom packaging. Greater brand recognition, improved customer loyalty, and a premium brand image all contribute to significant returns over time. These benefits often result in higher customer lifetime value and increased sales. By strategically planning and executing a custom packaging strategy, restaurants can gain a competitive edge and solidify their brand presence in the market.

Building Customer Loyalty Through Personalized Packaging

Smart restaurants are leveraging custom restaurant packaging to build stronger relationships with their customers, increase loyalty, and boost business growth. Understanding the psychology behind these personalized experiences and how they influence customer retention is key. A small gesture, like a handwritten thank-you note on a takeout bag, can create a sense of personal appreciation.

This seemingly minor detail can significantly impact customer loyalty and encourage repeat visits.

Personalization Strategies: From Simple to Sophisticated

Personalized packaging can range from simple, budget-friendly approaches to more intricate strategies. Handwritten notes, as mentioned above, are an excellent starting point. Including personalized messages on packaging inserts or stickers also adds a special touch.

For higher-volume businesses, variable printing systems offer a method to create unique packaging designs on a larger scale. This could include printing customer names, order specifics, or even special occasion messages directly onto the packaging.

Successful Personalization Campaigns

Many successful personalization campaigns illustrate the effectiveness of this strategy. Some restaurants have seen a rise in customer lifetime value through personalized loyalty programs connected to custom-designed packaging. Others have noticed lower churn rates by simply adding a personal element to their delivery service.

These positive outcomes highlight the value of building an emotional connection with customers.

Technology and Processes for Personalized Packaging

Effective personalized packaging initiatives require careful planning regarding technology and processes. Smaller restaurants can find affordable solutions, such as working with local print shops or using online design tools like Canva.

Larger establishments might choose to invest in specialized printing equipment or software. This investment allows them to automate the personalization process and seamlessly integrate it into their current workflow.

Measuring Personalization Impact

Measuring the effect of these personalization efforts is crucial. Tracking important metrics like customer feedback, repeat order frequency, and social media engagement offers valuable data. This information helps restaurants refine their personalization tactics and maximize their return on investment.

The personalized packaging market, which includes custom restaurant packaging, is growing significantly. Valued at $38.15 billion in 2025, it’s expected to reach $54.81 billion by 2032, with a CAGR of 5.3%. This growth is driven by increasing consumer demand for personalized products and the expansion of e-commerce. Around 36% of consumers are more likely to purchase from brands offering personalized products or packaging.

This data reveals a clear preference for customized experiences and presents a valuable opportunity for restaurants to strengthen customer relationships through personalized packaging.

Design Strategies That Make Restaurant Packaging Stand Out

Creating memorable custom restaurant packaging involves understanding design, brand consistency, and consumer psychology. Your packaging is a blank canvas: a way to tell your brand’s story and create a dining experience extending beyond the meal. From concept to finished product, design choices affect customer perception and drive engagement.

Balancing Aesthetics and Practicality

Effective packaging design balances looks with practicality. Food safety rules, durability for transport, and cost are all part of the process. Choosing a material that looks good and resists grease ensures both presentation and function. Strong designs prevent damage during delivery and maintain food presentation.

Key Design Principles for Customer Engagement

Here are some core design principles that boost customer engagement and brand perception:

- Color Psychology: Colors evoke feelings. Vibrant colors can stimulate appetite, while earthy tones suggest natural ingredients.

- Typography: Fonts communicate your brand’s personality. A modern font might suit a cafe, while a classic serif font might fit a traditional restaurant.

- Brand Consistency: Packaging should match your overall branding. Logos, colors, and messaging should create a cohesive brand identity.

To better illustrate the impact of different design elements, let’s look at a comparison:

Custom Restaurant Packaging Design Elements Comparison

| Design Element | Brand Impact | Customer Response | Cost Factor |

|---|---|---|---|

| Minimalist Design with Bold Logo | Reinforces brand identity through simplicity | Creates a modern, sophisticated feel | Generally cost-effective due to less ink usage |

| Intricate Patterns and Textures | Can convey a premium, artisanal brand image | Visually appealing, creates a tactile experience | Higher printing costs due to complexity |

| Eco-Friendly Materials (e.g., Kraft paper) | Projects a commitment to sustainability | Appeals to environmentally conscious consumers | Can be slightly more expensive than traditional materials |

| Bright, Vibrant Colors | Attracts attention, creates a sense of energy | Stimulates appetite, memorable | Moderate cost depending on ink coverage |

As you can see, each design element has unique benefits and cost implications. Choosing the right combination is key to maximizing impact.

Avoiding Common Design Mistakes

Some design pitfalls can hurt your brand:

- Cluttered Designs: Too much going on can overwhelm customers. Simplicity is often better.

- Inconsistent Branding: Mismatched logos or colors create confusion.

- Ignoring Functionality: Packaging that’s hard to open or doesn’t protect the food frustrates customers.

Working with Designers and Manufacturers

Working well with designers and manufacturers is crucial. Communicate your vision clearly with examples of designs you like. Discuss practical needs like materials and printing. Get feedback throughout the design process to ensure the final product meets your needs and brand.

Optimizing for Social Media and Delivery

Your packaging needs to be photogenic. Think about how it will look on social media. Bright colors, unique shapes, and interactive elements encourage sharing. Make sure your packaging stands out in deliveries, reinforcing your brand before the customer even opens it.

Sustainable Materials And Eco-Friendly Packaging Solutions

Today’s consumers are increasingly aware of environmental issues, and your restaurant’s packaging makes a first impression about your commitment to sustainability. Choosing eco-friendly custom restaurant packaging isn’t just a passing trend; it’s a core part of running a responsible business. This section looks at the exciting sustainable materials reshaping the food packaging industry, balancing function, environmental responsibility, and brand image.

Exploring Eco-Friendly Materials

The choices for sustainable custom restaurant packaging are growing fast, from plant-based plastics made from renewable resources like cornstarch to biodegradable alternatives created from sugarcane bagasse (the dry pulpy fibrous residue that remains after sugarcane or sorghum stalks are crushed to extract their juice). These materials offer similar performance to traditional packaging while greatly lessening environmental impact. This lets restaurants maintain food quality and safety while meeting customer demand for greener choices.

Balancing Sustainability, Functionality, and Cost

Finding the right balance between these three key elements is essential for successful, sustainable packaging. Some eco-friendly materials may have a higher initial cost. However, the long-term benefits – like a better brand image and a smaller environmental footprint – often make up for the investment. For example, switching to compostable containers can decrease waste going to landfills and attract environmentally conscious customers.

Sustainability Certifications and Supplier Vetting

Prioritizing sustainability certifications, such as those from the Sustainable Forestry Initiative (SFI) or the Forest Stewardship Council (FSC), helps guarantee responsibly sourced materials. Careful supplier vetting is also critical. This helps verify authentic, eco-friendly practices all along the supply chain. This due diligence shows your genuine commitment to sustainability and builds customer trust.

Communicating Your Environmental Efforts

Clearly showing your sustainability efforts through packaging design reinforces your brand’s environmental commitment. Labeling packaging with certifications and using designs that communicate eco-friendliness—like leaf motifs or earth tones—can connect with environmentally aware consumers. High-quality restaurant menu photos can enhance custom packaging and improve the overall brand presentation. This transparent communication builds customer trust and loyalty.

Success Stories and Cost Analysis

Many restaurants have successfully made the change to sustainable custom packaging. They’ve seen positive effects on their brand reputation and customer loyalty. These success stories highlight the real-world advantages of adopting eco-friendly practices. Looking at the total cost of ownership for sustainable packaging—including disposal costs and potential savings from less waste—offers a complete picture of the financial impact. By carefully considering these factors and measuring environmental impact alongside business results, restaurants can make smart decisions about their packaging and do their part for a more sustainable future.

Implementation Guide From Concept To Customer Delivery

Ready to transform your restaurant’s image with custom packaging? This guide breaks down the process, from initial idea to final delivery, covering the essential operational details often missed during the design phase. These details include crucial aspects like minimum order quantities, lead times, quality control, and inventory management. Understanding these elements upfront ensures a smooth and efficient transition to your new packaging.

Planning and Supplier Collaboration

First, define your packaging needs and budget. Thorough research of potential suppliers is essential. Look for suppliers experienced in custom restaurant packaging and knowledgeable about food safety regulations. Requesting samples and comparing pricing is a smart move. Open communication with your chosen supplier is vital throughout the process. This collaboration guarantees your vision aligns with their production capabilities.

Minimum Order Quantities and Lead Times

Understanding minimum order quantities (MOQs) is essential for effective cost management. Suppliers often have minimum unit requirements, potentially impacting your budget, especially for smaller restaurants. Don’t forget lead times, the time from order placement to delivery. Accurate lead time estimations prevent inventory shortages and ensure timely delivery.

Quality Control and Inventory Management

Implement robust quality control procedures throughout the process, from design approval to final production. This guarantees the final product meets your expectations. An effective inventory management system is vital for tracking stock levels and preventing overstocking or shortages. This minimizes waste and optimizes valuable storage space.

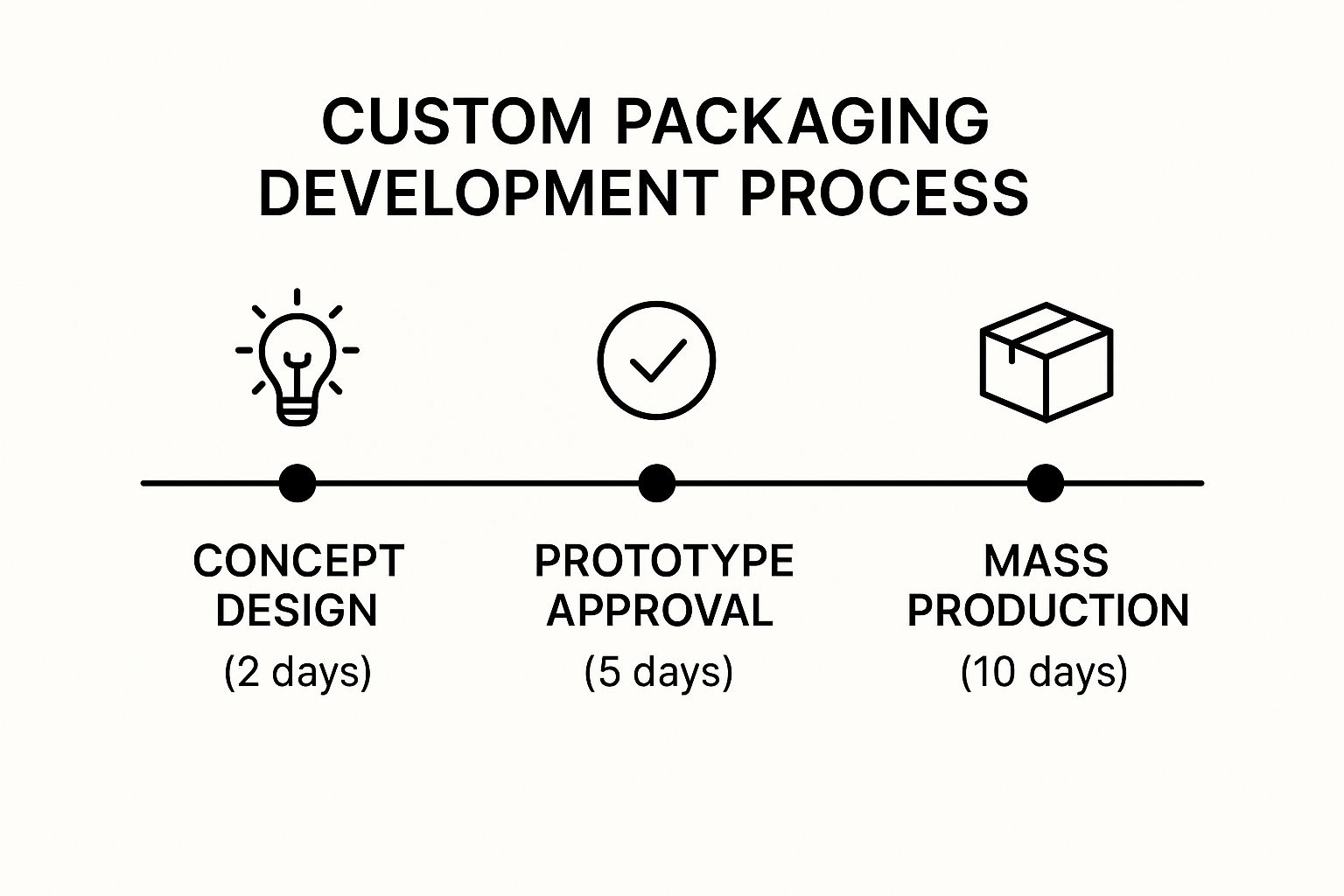

This infographic visualizes a typical timeline for custom restaurant packaging development. It shows the duration of Concept Design, Prototype Approval, and Mass Production. A typical project takes 17 days from concept to production, emphasizing the importance of realistic lead times in your plan.

To help you plan effectively, here’s a sample implementation timeline:

Custom Restaurant Packaging Implementation Timeline

| Phase | Duration | Key Activities | Deliverables |

|---|---|---|---|

| Concept Design | 3 days | Brainstorming, sketching, and initial design concepts | Initial design mockups |

| Prototype Approval | 4 days | Prototype creation, review, and revisions | Approved prototype sample |

| Mass Production | 10 days | Manufacturing, printing, and quality control | Final packaged products |

This table provides a general overview. Remember to work closely with your supplier to establish a timeline that fits your specific project needs.

Staff Training and Customer Testing

Train your staff on new packaging procedures for a seamless transition. This could involve assembling new boxes or using tamper-evident seals. Before a full launch, consider testing your custom restaurant packaging with a small group of customers. Gather feedback on ease of use, aesthetics, and overall satisfaction. This feedback can identify any issues before full implementation.

Maintaining Consistency and Troubleshooting

For restaurants with multiple locations, packaging consistency is crucial for brand identity. Establish clear guidelines and quality control across all branches. Develop a plan for addressing potential challenges like supplier delays or unexpected design issues. Proactive troubleshooting minimizes disruptions and keeps your packaging launch on schedule. By carefully managing these implementation steps, you can successfully introduce custom packaging that enhances your brand and elevates the customer experience.

Measuring Success and Maximizing Packaging Investment ROI

Understanding the return on investment (ROI) from custom restaurant packaging means tracking the right metrics. It’s about connecting packaging changes to real business outcomes, not just appreciating a new design. This section explores proven methods to measure success, from social media engagement to customer feedback.

Establishing Baseline Measurements and Setting Expectations

Before introducing new packaging, establish baseline measurements. Track metrics like current order frequency, average order value, and customer satisfaction scores. These initial figures will serve as your benchmark for comparison after implementing the custom packaging. It’s important to set realistic expectations. Packaging itself isn’t a miracle worker, but rather a key component of a larger brand strategy.

Tracking Progress: Quantitative and Qualitative Metrics

Monitor both quantitative and qualitative indicators for a complete picture of your packaging’s performance. Quantitative metrics such as order frequency, average order value, and website traffic offer hard data. For example, a 10% increase in average order value after introducing premium packaging is a clear positive indicator.

Don’t neglect qualitative data. Customer feedback through surveys and social media comments provides invaluable insights into brand perception and satisfaction. Positive online reviews mentioning your packaging are powerful social proof.

Advanced Techniques for Analyzing Customer Behavior

Delve deeper into customer behavior by analyzing customer lifetime value (CLTV). This involves calculating the total revenue generated by a customer throughout their relationship with your restaurant. An increase in CLTV after a packaging change suggests that your packaging encourages repeat business, revealing long-term financial benefits.

Identifying High-Impact Packaging Elements

Not all packaging elements are created equal. A/B testing different packaging versions, such as varying the color scheme or messaging, helps identify the design choices that resonate most with your target audience. This allows you to refine your packaging strategy for maximum impact, similar to website layout optimization.

Using Data to Refine Strategies and Optimize Investments

Successful restaurants use packaging performance data for continuous improvement. Just as a chef refines a recipe based on feedback, you can adjust packaging design, materials, or messaging based on customer response. This data-driven approach ensures your packaging investment delivers a strong ROI.

Ready to elevate your takeout experience with custom packaging? Visit MrTakeOutBags.com to explore a wide selection of customizable solutions. Their expert team offers personalized consultations to help you create packaging that elevates your brand and delights your customers.

Comments are closed.