Understanding the Regulatory Landscape That Actually Matters

Trying to navigate the world of food packaging regulations can feel like you’re piecing together a puzzle without all the pieces. The real secret isn’t to memorize every single rule, but to understand the system and what regulators truly care about. You’ll find success when you start to see the patterns that distinguish strict, non-negotiable requirements from the broader priorities of bodies like the FDA in the U.S. and the EFSA in Europe.

For example, while both agencies have massive rulebooks, their main focus is always on consumer safety. They need absolute certainty that nothing harmful will seep from your packaging into the food. This is why things like migration testing for plastics are a deal-breaker, whereas the exact font size on a non-critical part of your label might not draw as much attention during an inspection.

From Requirements to Priorities

Think of it like this: a requirement is the letter of the law, but a priority is its spirit. A company that just scrapes by meeting the bare minimum is always walking a thin line. On the other hand, a business that gets the why behind the rules can weave compliance into its daily operations. This proactive approach means focusing on:

- Material Safety: Intentionally choosing certified food-safe materials and always demanding proper documentation from your suppliers. Don’t just take their word for it.

- Label Accuracy: Making sure that allergen warnings and nutritional information are perfect. A mislabeled allergen is a huge red flag for regulators because of the immediate health risks involved.

- Traceability: Having a reliable system in place to quickly track down a specific product batch if a recall ever becomes necessary.

The Growing Influence of Sustainability

We’re also seeing a major shift in priorities, pushed by both customer demand and new legislation. Sustainability is no longer just a nice-to-have footnote in food packaging regulations; it’s moving to the front page. Projections show that by 2025, 60% of all food packaging will be recyclable, biodegradable, or reusable.

This isn’t just a passing trend; it’s a direct result of growing regulatory pressure and a market that increasingly values environmental responsibility. This change is also happening at the local level.

Building a Compliance System That Actually Works

Vague promises and crossed fingers won’t protect you when an inspector shows up. Real compliance with food packaging regulations is built on a solid, actionable system, not just good intentions. This means moving beyond a simple checklist and creating a living process that grows and changes with your business.

A smart approach starts with assigning clear ownership. Who on your team is the point person for tracking regulatory updates? Is it the procurement manager who orders the packaging or the quality assurance lead? Without a designated owner, important tasks will inevitably fall through the cracks. For small bakeries, this might be the owner themselves. For a larger catering company, it could be a dedicated operations manager.

Creating an Early Warning System

Next, think about building an “early warning system” for potential issues. This isn’t as complex as it sounds. It could be as simple as a quarterly review meeting where your team discusses:

- Any new packaging materials being considered.

- Feedback from your suppliers about material availability or changes.

- New markets you plan to enter and their specific rules.

- Customer complaints related to packaging integrity or labeling.

This proactive mindset helps you spot problems before they turn into expensive recalls or legal troubles. A great example is when a supplier informs you that their go-to plastic resin is being reformulated. An effective system triggers an immediate response: requesting updated compliance documents and checking if the new formula still meets FDA or EFSA standards for food contact.

To help you structure your strategy, here’s a look at how different-sized companies can approach compliance.

Compliance Strategy Framework Comparison

A comparison of different compliance approaches based on company size and complexity

| Company Size | Recommended Approach | Key Focus Areas | Resource Requirements |

|---|---|---|---|

| Small Business (e.g., local bakery) | Basic & Reactive | Supplier documentation, basic labeling, staff training | Low (often owner-managed) |

| Medium Business (e.g., regional distributor) | Structured & Proactive | Dedicated compliance role, regular supplier audits, early warning system | Medium (part-time or dedicated staff) |

| Large Enterprise (e.g., national brand) | Integrated & Predictive | Full compliance team, automated tracking systems, in-house testing | High (dedicated team, specialized software) |

As the table shows, your strategy needs to match your operational scale. A small bakery can manage with diligent record-keeping, while a national brand needs a much more robust, tech-supported framework.

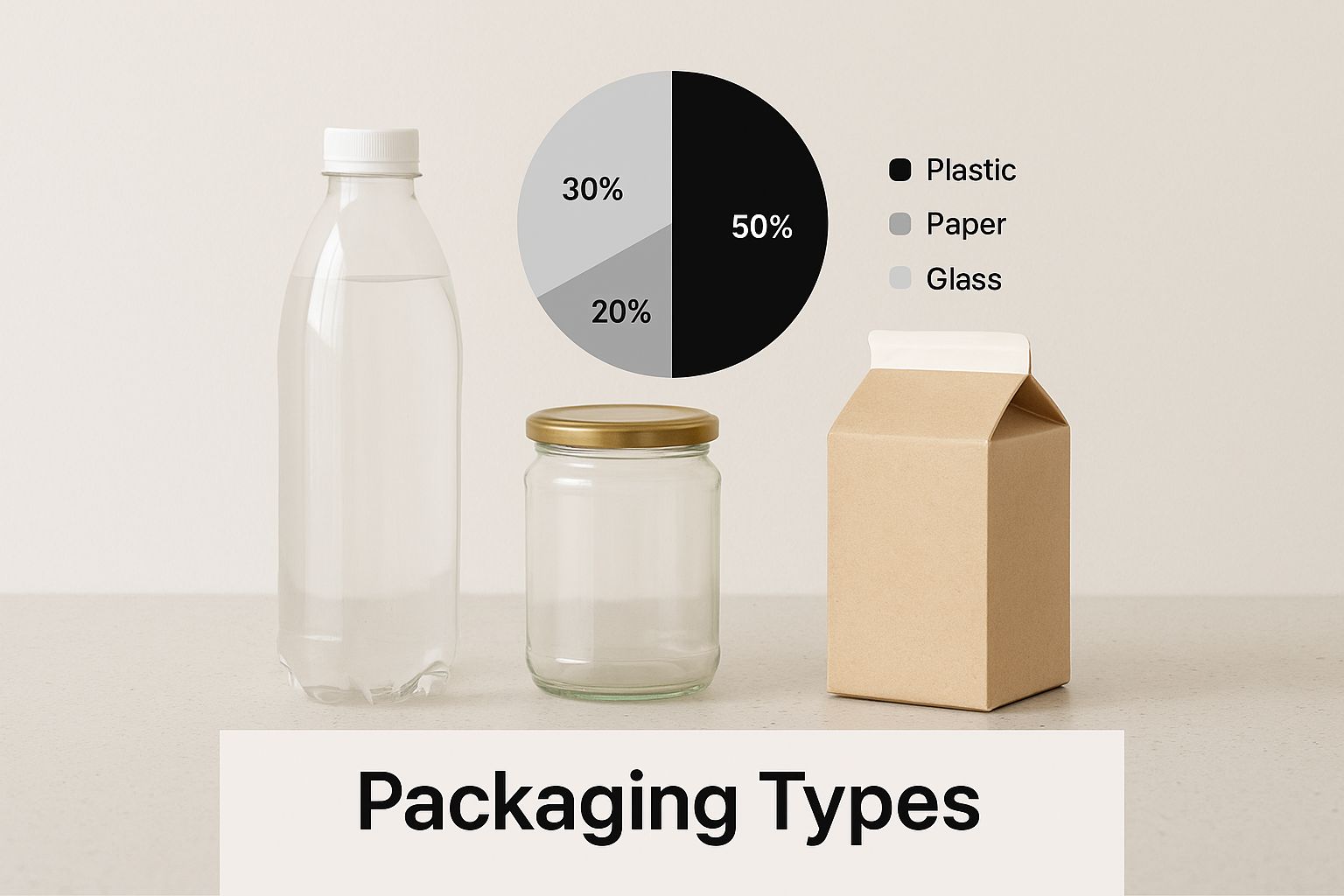

The visual below shows the variety of common packaging types, each with its own set of compliance considerations.

This graphic drives home the point that a one-size-fits-all compliance strategy rarely works. The rules for a glass jar are very different from those for a paper carton. Your system must be flexible enough to handle the specific food packaging regulations for every material you use, making sure nothing is overlooked.

Mastering Material Safety Without a Science Degree

When you hear the term “migration testing,” you might picture a lab coat and a Ph.D., but the concept is actually straightforward. Regulators just need assurance that your packaging won’t transfer unwanted chemicals into the food it’s holding. Getting a handle on this basic idea is the key to mastering material safety for your business. It’s not about becoming a chemical engineer; it’s about asking smart questions and getting the right documents from your suppliers.

Think about it this way: a plastic container holding acidic tomato sauce will react differently than one holding dry pasta. Factors like heat, acidity, and fats can all encourage substances to move, or “migrate,” from the packaging into the product. Your role is to make sure you’re using the right tool for the right job.

Asking the Right Questions

Before you invest in a new type of packaging, it’s time for a frank conversation with your supplier. Your main goal is to secure a Declaration of Compliance (DoC). This document is your official confirmation that the material is safe for how you plan to use it.

When you talk to them, be ready with the specifics. Here’s what you should cover:

- Intended Use: Don’t just say “food.” Be precise. Are you packaging hot, oily soup or cold sandwiches?

- Temperature Conditions: Will the food be frozen, kept in a fridge, or heated in a microwave directly in the container?

- Food Type: Is your product mostly acidic (like citrus), fatty (like cheese), or dry (like crackers)?

A trustworthy supplier will have no problem providing a DoC that verifies the packaging has been tested for your exact needs. If they seem hesitant or vague, consider that a major red flag.

Beyond Safety: The Rise of Recycled Content

Today, material safety is also tied to sustainability. Global food packaging regulations are changing fast, with a growing emphasis on recyclability and the use of post-consumer materials. For example, new rules expected around 2025 will require many plastic packaging types to include a certain percentage of recycled content. This move merges consumer protection with environmental responsibility.

Turning Sustainability Rules Into Business Opportunities

Shifting sustainability rules, especially those around Extended Producer Responsibility (EPR), are changing how businesses think about their packaging. These new rules don’t have to be just another line item on your expense report; they can be a real chance to innovate and pull ahead of the competition. Instead of viewing them as a hassle, smart companies are finding ways to turn compliance with these food packaging regulations into a genuine advantage, uncovering cost savings and new market opportunities along the way.

From Compliance Cost to Competitive Edge

The main idea is to look at your packaging materials not just for their primary function, but for their entire lifecycle. Can your current containers be easily recycled where your customers live? Could you switch to a lighter material to cut down on shipping costs and EPR fees? Imagine swapping a heavy glass jar for a lightweight, recyclable pouch. This simple change could lower both your material costs and the fees associated with disposal.

Another effective strategy is to build a closer relationship with your suppliers. Start a conversation about their sustainability goals and what new materials they’re working on. A great partner will be able to offer materials that are not only compliant but also cost-effective and appealing to your customers. This kind of collaboration can lead to better packaging that meets regulations and wins over eco-conscious shoppers. These projects could range from using mono-materials for easier recycling to adopting packaging with better product protection.

Navigating Upcoming EPR Reforms

Looking ahead to 2025, regulations around the world are getting tougher to reduce waste. The United Kingdom, for instance, is overhauling its EPR system, putting more of the financial weight for packaging’s end-of-life costs directly on manufacturers. This is a strong signal that the cost of doing nothing will only increase.

Building a Supply Chain That Supports Your Success

Your commitment to food packaging regulations is only as strong as your weakest supplier. A solid compliance strategy has to reach beyond your own operations and into every part of your supply chain. This means you can’t just take a supplier’s word that their materials are safe; you have to actively verify it. Building these strong, compliant relationships starts with asking detailed questions before you even place an order.

Think of it as hiring a critical team member. You wouldn’t bring someone on board without checking their references, and you shouldn’t start a partnership with a packaging supplier without seeing their documentation. This process isn’t about micromanaging; it’s about setting clear, shared expectations from the very beginning. It protects both you and your partners from expensive mistakes and recalls down the road.

Vetting Your Partners and Auditing Effectively

A great way to start is by creating a simple supplier questionnaire. Ask potential partners to provide their food-grade certifications, Declarations of Compliance (DoC) for the specific materials you’re buying, and information about their own traceability systems. A trustworthy supplier will have this information ready to go and will appreciate your diligence. If you get hesitation or vague answers, consider it a major red flag.

Beyond the initial paperwork, occasional audits are crucial. This doesn’t have to be a formal, white-glove inspection. It can be as straightforward as:

- Regularly requesting updated compliance documents, especially if a material formulation changes.

- Physically checking incoming packaging shipments to ensure they match what you ordered and are correctly labeled with batch numbers.

- Having a backup supplier identified. Even the best partners face disruptions, and having a pre-vetted alternative can be a lifesaver.

To help you organize this process, a simple checklist can ensure you cover all your bases with every supplier, every time.

Supplier Compliance Checklist

This table outlines the essential requirements and documentation you should collect from your packaging suppliers to ensure they meet your standards.

| Requirement Category | Specific Requirements | Documentation Needed | Verification Method |

|---|---|---|---|

| Material Safety | Materials are approved for food contact. | Declaration of Compliance (DoC) | Review and file the DoC for each specific material. |

| Quality Control | Consistent material quality with no defects or contaminants. | Certificate of Analysis (CoA) | Perform spot-checks on incoming shipments against the CoA. |

| Traceability | All packaging is clearly marked with batch or lot numbers. | Supplier’s internal traceability records. | Confirm that batch numbers are present and legible upon delivery. |

| Regulatory Standing | Supplier holds a GFSI-recognized certification (like BRC or SQF). | Current and valid certification documents. | Check the certificate’s validity on the issuing body’s website. |

Using a checklist like this turns a big task into a manageable one. It makes sure that you’re not just hoping for compliance but are actively building a supply chain you can depend on.

Staying Ahead of Changes Before They Hit You

The smartest businesses don’t just react to new food packaging regulations; they see them coming and prepare in advance. This forward-thinking approach isn’t about having a crystal ball—it’s about knowing where to look for early signs and building flexibility into your operations so you’re never caught off guard.

Interpreting Proposed Regulations

Your first line of defense is keeping an eye on official government sources. For instance, the U.S. Food and Drug Administration (FDA) regularly provides updates on food contact substances and other packaging materials.

The trick is to watch for proposed rules, not just the final regulations. These proposals are a clear signal of where the industry is heading, giving you precious lead time to figure out how they might affect your business and what adjustments you’ll need to make.

Building Flexibility into Your Operations

Once you have this insight, your next move is to build agility. This means avoiding being locked into a single packaging type or supplier. A great strategy is to have ongoing conversations with your suppliers about the innovative materials they are developing.

For example, if you notice a growing push for more sustainable materials, you can get ahead of the curve by exploring options that meet those future standards.

A few proactive habits can make a huge difference:

- Subscribe to newsletters from regulatory bodies like the FDA or the European Food Safety Authority (EFSA).

- Attend industry webinars where experts break down emerging regulatory trends.

- Keep an open line of communication with your packaging suppliers about new materials and potential changes on their end.

This approach keeps you prepared, ensuring you’re not scrambling when a new rule finally drops. It’s about turning regulatory changes from a potential headache into a strategic advantage for your business.

Key Takeaways and Your Next Actions

Trying to figure out food packaging regulations can feel overwhelming. The key isn’t to solve everything at once, but to make smart, targeted choices that protect your business. Your path to compliance starts with building a solid base of knowledge and taking a few proactive steps.

Your Immediate Action Plan

To get rolling, let’s focus on the tasks that will give you the most bang for your buck. These aren’t long-term projects; they’re things you can do this week to seriously lower your risk.

- Audit Your Top 5 Products: Grab the Declarations of Compliance (DoC) for the packaging you use on your five best-selling menu items. Are the documents current? Do they actually cover how you use them (like for hot, acidic foods)? If you can’t find these documents, your number one priority is to get them from your supplier.

- Talk to Your Primary Supplier: Set up a quick 15-minute call. Ask them one straightforward question: “What regulatory changes are you tracking that might affect us in the next 12 months?” Their answer is gold, giving you a peek into the future.

- Review Your Labels: Look closely at your packaging for any claims like “organic,” “recyclable,” or “compostable.” Do you have the proper certifications to back these up? Misleading claims are a common headache that’s surprisingly easy to avoid.

Building a Long-Term Compliance Framework

Once you’ve handled the urgent stuff, it’s time to create a system that makes managing food packaging regulations a regular part of your routine. This is about building good habits, not just checking off a list. Think of this as your 90-day goal.

First, assign clear ownership for compliance. Even if you’re a small shop, one person needs to be the go-to for tracking new rules and supplier paperwork. Second, create a simple supplier scorecard. You can use this to rate your partners on things like how well they communicate, the quality of their documentation, and if they give you a heads-up on changes. Finally, schedule a quarterly compliance check-in on your calendar. This dedicated time ensures that compliance stays on the radar and doesn’t get buried under daily tasks.

Ready to find packaging partners who make compliance easier? At MrTakeOutBags.com, we provide clear documentation and expert advice to help you navigate the complexities of food safety. Explore our extensive selection of compliant packaging solutions and let our team support your success.

Comments are closed.