Understanding What Food Packaging Safety Really Means

When we talk about food packaging safety, it’s easy to get tangled up in rules and regulations. But at its heart, it’s not about just meeting the bare minimum. It’s about shifting your thinking so that your packaging becomes the first, and most important, line of defense for your product and your customers.

From Compliance to Culture

Imagine two different businesses. One sees an upcoming FDA inspection as a test they need to cram for, frantically updating logs moments before the auditor shows up. The other operates with high standards every single day, making the inspection just another Tuesday. This is the difference between compliance and a true safety culture.

The same idea applies to food packaging safety. Companies that get it right don’t just follow the rules; they build safety into everything they do. They view their packaging not as a necessary expense, but as a direct investment in their brand’s reputation and customer trust. A caterer choosing a tamper-evident container over a basic clamshell isn’t just spending a few extra cents; they’re sending a clear message that they care about quality and safety.

Proactive Hazard Spotting

This forward-thinking approach is essential because the stakes are incredibly high. Food contamination is a serious global issue, with statistics showing that every 1 in 10 people worldwide is affected by it. This fact alone shows why we need packaging that does more than just hold food.

Ultimately, a strong safety system is about spotting potential problems before they turn into expensive mistakes. It means getting into the habit of asking practical questions about your packaging choices. “Could this seal break if the box is dropped during delivery?” or “Will the acid from this tomato sauce react with this material over time?”

True food packaging safety is about embedding these questions into your daily operations. When you do that, your packaging stops being a simple container and starts being your product’s most reliable guardian.

Making Sense Of FDA Rules Without Losing Your Mind

Diving into FDA regulations can feel like a full-time job, but it all boils down to one core principle: making sure nothing harmful moves from the package into the food. With the global food packaging market projected to grow at a CAGR of 5.30%, mastering these rules is no longer optional.

The U.S. FDA’s primary tool for this is the Food Contact Notification (FCN) program. Essentially, it’s a required scientific safety review for new materials before they can be used in packaging. For any business in the food industry, understanding how this works is a fundamental part of food packaging safety.

The Reality of Chemical Migration

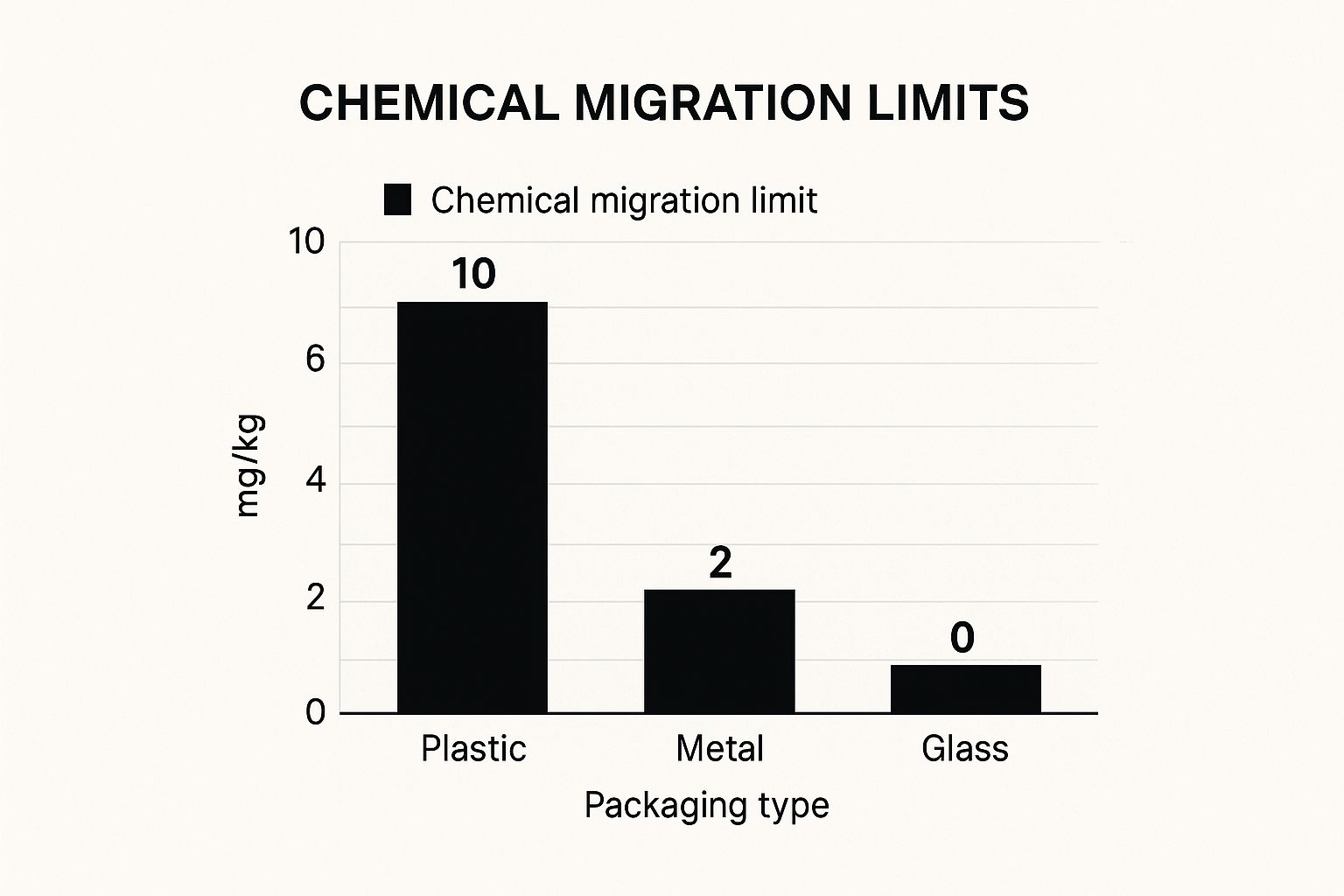

The main concern driving all this regulation is chemical migration—the technical term for when substances from the packaging itself can transfer into the food it’s meant to protect. Different materials pose different levels of risk, which is why they are regulated differently. The smartest companies don’t just react; they create internal systems to manage documentation and build strong relationships with suppliers who are already compliance experts.

This infographic shows the maximum allowed chemical migration limits for some of the most common packaging materials.

You can see that materials like glass have nearly zero migration, making them an incredibly stable and safe option. Having this kind of knowledge helps you make better sourcing choices from day one.

To give you a clearer picture, let’s compare some of the key FDA regulations you might encounter. This table breaks down what’s required for different types of submissions, how long you can expect to wait, and what you should keep in mind for each.

Key FDA Food Packaging Regulations Comparison

A comprehensive comparison of major FDA regulations affecting food packaging, including requirements, timelines, and compliance costs

| Regulation Type | Requirements | Approval Timeline | Key Considerations |

|---|---|---|---|

| Food Contact Notification (FCN) | Detailed chemistry, toxicology, and migration data for a specific substance from a specific manufacturer. | Becomes effective 120 days after FDA receipt, unless the FDA objects. | This is proprietary to the company that submits it (the notifier). It’s generally faster than a Food Additive Petition. |

| Generally Recognized as Safe (GRAS) Notice | Evidence showing general agreement on the substance’s safety among qualified experts. | FDA typically responds with a “no questions” letter within 180 days, though this can be extended. | This applies to the substance itself, not just one manufacturer. The burden of proof for “general recognition” is high. |

| Food Additive Petition (FAP) | Extensive safety, toxicology, and environmental data to establish safe conditions of use for a new additive. | Can take several years due to the in-depth, multi-stage review process. | This is the most rigorous path. If approved, it creates a new regulation that allows anyone to use the additive under the specified conditions. |

The main takeaway here is that the FCN process is the most common path for new packaging materials, offering a predictable timeline. GRAS is for substances with a well-established safety profile, while a Food Additive Petition is a much bigger undertaking reserved for entirely new additives.

Building a Compliance-Ready Operation

Instead of viewing regulations as a hurdle, think of them as a practical guide to quality control. The key is to be proactive rather than waiting to react to a problem.

- Vet Your Suppliers: Don’t just take their word for it. A reputable partner should readily provide a Letter of Guaranty, which confirms their products meet FDA standards for direct food contact. This document is your first and most important line of defense.

- Document Intended Use: Compliance is all about the details. A plastic container that’s safe for a dry salad isn’t automatically suitable for a hot, acidic soup. You must clearly define and document the intended use for every packaging item, including food types and temperature limits. This simple step prevents major compliance headaches down the line.

Spotting And Eliminating Chemical Threats Before They Strike

Chemical contamination isn’t some far-off problem; it can be happening right under your nose. Certain substances like phthalates and bisphenol A (BPA), which were once staples in plastic manufacturing, can actually move from the packaging into the food itself. This process, called leaching, happens most often when packaging is heated or holds fatty foods, putting a serious dent in your food packaging safety efforts.

This isn’t just a hypothetical risk. A real wake-up call came from a 2024 report that found many everyday foods contain high levels of these exact chemicals, sometimes far exceeding safety limits. It’s a clear signal that choosing the right materials is essential for protecting your customers and your brand’s good name.

How To Get Ahead Of Chemical Risks

Switching away from these questionable materials doesn’t mean you have to wreck your budget. It’s about being intentional and asking the right questions long before you’re locked into a contract with a packaging supplier. Smart companies are already making these moves to prevent future problems and build a foundation of trust with their customers.

Here are a few practical ways to keep chemical threats out of your supply chain:

- Dig Deeper with Your Suppliers: Don’t just settle for a simple “Is it food-safe?” answer. Ask for a complete material disclosure or a Letter of Guaranty that explicitly confirms the absence of BPA, phthalates, and other specific chemicals you’re worried about. A good partner will have this information ready; if they hesitate, consider it a warning sign.

- Match the Material to Your Product: Not every plastic is suitable for every food. If you sell oily or acidic products, look into materials like PET (polyethylene terephthalate) or consider alternatives like glass and certified BPA-free options. Their chemical structures are much more stable, which dramatically lowers the risk of leaching.

- Ask for Real-World Test Results: Your supplier should provide migration testing data that reflects how your customers will actually use the product. If you sell hot soup, you need to see test results performed under heated conditions, not just at room temperature. This is the only way to know if the packaging is truly safe for its intended purpose.

Building Quality Control Systems That Actually Catch Problems

Giving your packaging a quick once-over before it heads out the door just doesn’t cut it. That’s not a real quality check—it’s wishful thinking. A proper quality control (QC) system is your best defense, catching problems long before they have a chance to disappoint a customer. Real food packaging safety isn’t about luck; it’s built on solid, repeatable processes that you can count on.

Putting Your QC Plan Into Motion

A strong QC framework is more than a dusty binder on a shelf that gets reviewed once a year. It’s a living part of your daily operations. It all starts with your people. Continuous employee training is essential, making sure every team member knows the right way to handle materials and run the machinery. This is your first line of defense against human error, which is often where safety issues begin.

Your quality checks should also extend to your suppliers. Don’t just take their word for it or glance at a certification. Dig into their processes to confirm they meet your standards. Internally, you need to track key metrics like material consistency and seal integrity. If you suddenly see a 10% rise in faulty seals, that’s your early warning sign to check for a machine calibration problem or a bad batch of material.

Designing Tests That Reflect Reality

Your testing methods have to be based on the real world, not just a perfect lab setting. What happens to your packaging once it leaves your facility? It gets bumped, dropped, stacked, and exposed to changing temperatures. Your tests should replicate this journey as closely as possible.

Consider these practical tests to get a true picture of your packaging’s performance:

- Seal Integrity Tests: These use pressure or vacuums to check if seals can handle altitude changes during shipping or just rough handling from a delivery driver.

- Drop and Vibration Tests: Simulating the shakes and tumbles of a delivery truck will quickly reveal any structural weak points in your containers.

- Temperature Stress Tests: Your packaging might sit in a hot truck or a cold freezer. These tests expose it to those extremes to see how it holds up.

To help you decide which tests are right for your operation, here’s a comparison of some essential quality control methods. This table breaks down what each test looks for, along with its relative cost, time commitment, and overall reliability.

Essential Quality Control Testing Methods

Comparison of different testing methods for food packaging safety, including costs, timeframes, and effectiveness ratings

| Testing Method | Detection Capability | Cost Range | Time Required | Reliability Score |

|---|---|---|---|---|

| Seal Integrity Test | Detects micro-leaks, weak seals, and pinholes. | $$ | Minutes per sample | 4/5 |

| Drop & Vibration Test | Identifies structural weaknesses, poor design, and potential for breakage in transit. | $$$ | Hours | 5/5 |

| Temperature Stress Test | Reveals material warping, delamination, or seal failure under heat/cold. | $$$ | Days | 4/5 |

| Migration Test | Checks for chemical leaching from packaging into food. | $$$$ | Weeks | 5/5 |

| Visual Inspection | Catches obvious defects like misprints, tears, or incorrect assembly. | $ | Seconds per sample | 2/5 |

As you can see, no single test covers everything. While a quick visual inspection is cheap and fast, its reliability is low. The most effective QC systems use a combination of these tests to ensure packaging is safe, secure, and ready for the real world.

Balancing Sustainability Goals With Safety Requirements

Does going green with your packaging mean you have to worry about safety? It’s a common concern. Many restaurant owners feel stuck between meeting sustainability goals and upholding strict food packaging safety standards. The good news is that you don’t have to choose. Top businesses are already proving that you can protect both your food and the planet without any tradeoffs.

Rethinking Eco-Friendly Materials

The trick is to apply the same safety scrutiny to sustainable options as you would to any traditional material. Think about glass, for example. It’s not just recyclable; it’s also completely inert, meaning it won’t react with or leach into food, which makes it an incredibly safe choice.

Even newer options, like compostable bioplastics (PLA) made from corn starch, are perfectly safe when they come from a reliable source. It’s all about looking past the “eco-friendly” sticker and understanding the material itself.

Navigating the Shift Without Compromise

Making the switch to sustainable packaging is becoming the new standard. In fact, over 40% of companies are planning to use more sustainable packaging by 2025. This isn’t just a feel-good move; it’s a direct response to customer preferences and changing regulations. This global demand is fueling the creation of materials that are both environmentally friendly and safe for food.

So, how do you make the change without any sleepless nights? It comes down to being just as diligent with these new materials as you are with your current ones.

- Verify Certifications: Don’t just take a supplier’s word for it. Always ask for the documentation that proves a recycled or compostable material is officially certified as food-grade.

- Test for Your Use Case: Will that new plant-based bowl hold your piping-hot soup? Can it handle oily dressings without getting weak? Put potential containers through real-world tests in your own kitchen with your own menu items.

Ultimately, this isn’t about compromise. It’s about seeing that a high-quality container delivers on both environmental responsibility and absolute food packaging safety.

Managing Suppliers Who Actually Care About Safety

Your promise of food packaging safety is directly tied to the quality of the materials you bring in. A weak link in your supply chain can unravel all your hard work, which is why choosing a vendor is one of the biggest calls you’ll make for your business. You’re looking for a partner, not just a provider.

Qualification That Goes Beyond a Certificate

Any supplier can wave a food-safe certificate in your face, but that piece of paper doesn’t tell the whole story. To find out who is truly committed, you have to dig a little deeper. Instead of just taking their word for it, ask to see their Standard Operating Procedures (SOPs) for hygiene and material handling.

A partner who is proud of their process will have these documents ready to go. Go a step further and ask for their sanitation logs and records of staff training. If they get defensive or can’t seem to find them, that’s a major red flag. This diligence is especially important when you’re balancing safety with sustainability goals.

Building a Partnership on Communication

So, you’ve found a supplier that seems to check all the boxes. The work doesn’t stop there. To keep those high standards, you need to build a relationship with clear and consistent communication. Think of it as a partnership focused on shared success, not just a series of transactions.

Here’s how you can make that happen:

- Put it in writing. Your contract should clearly spell out your non-negotiable quality and safety standards. Include everything from material specifications to the exact conditions for rejecting a shipment.

- Schedule regular check-ins. Don’t just wait for an annual review. A quick quarterly phone call can help you catch small issues before they snowball into big problems.

- Know who to call. If a shipment arrives and it’s not right, you need a clear process for who to contact and how to escalate the issue. Time is critical when a bad batch comes in.

Getting this partnership right is the foundation of your packaging strategy, whether you’re ordering custom bags, boxes, or specific disposable food containers.

Your Food Packaging Safety Action Plan

Knowing the rules of food packaging safety is one thing, but putting that knowledge into practice is what really counts. A solid food packaging safety program isn’t something you create once and forget about; it’s a living part of your operation that you constantly check and improve. The best place to start is with a straightforward, honest look at where your business currently stands.

Conducting Your Initial Safety Audit

Begin by asking some direct questions to find your biggest weak spots. This isn’t about pointing fingers; it’s about finding opportunities to make quick, meaningful improvements that protect your customers and your brand.

- Supplier Verification: Can you pull out an up-to-date Letter of Guaranty for every single food-contact item you use? If not, it’s time to make a priority list and give yourself a deadline to track them all down.

- Material-to-Food Mismatch: Are you packing that hot, acidic pasta dish in a container designed for a cold garden salad? Map out every item on your menu to its specific container to catch these common but critical safety gaps.

- Staff Knowledge: Is your team 100% certain which containers can go in the microwave and which are a definite no-go? Consistent, simple training can prevent some major headaches and customer complaints down the road.

A big part of this process is verifying the claims your suppliers make. It’s always good practice to check official sources yourself. For instance, the FDA has a public database of all effective Food Contact Notifications (FCNs).

This tool gives you a clear view of which materials have been approved for specific uses, allowing you to confirm a supplier’s paperwork with official data. Your audit creates a starting point to track your progress. Seeing your list of fully-verified suppliers grow from 50% to 95% in six months is a fantastic measure of success. These real results are what turn your action plan from just a document into a true culture of safety.

Ready to partner with a supplier who takes safety as seriously as you do? Explore our full range of compliant packaging at MrTakeOutBags.com.

Comments are closed.