The Essential Guide to Takeout Container Dimensions

Choosing the right takeout container size is crucial for ensuring your food arrives in perfect condition. It’s a balance between the type of food, portion size, and the delivery trip itself. The right container keeps food looking good, prevents spills, and keeps customers happy.

Understanding Standard Sizes

Takeout containers, like clothing, come in a range of sizes. From small sauce cups to large family-style containers, there’s a fit for every dish. Sizes are measured in ounces (oz) or milliliters (ml) for volume, and in inches or centimeters for dimensions.

- Small containers (8-16 oz): Perfect for sauces, sides, or small appetizers.

- Medium containers (24-32 oz): Great for individual entrees, salads, and sandwiches.

- Large containers (48+ oz): Best for family meals, combination platters, or large portions.

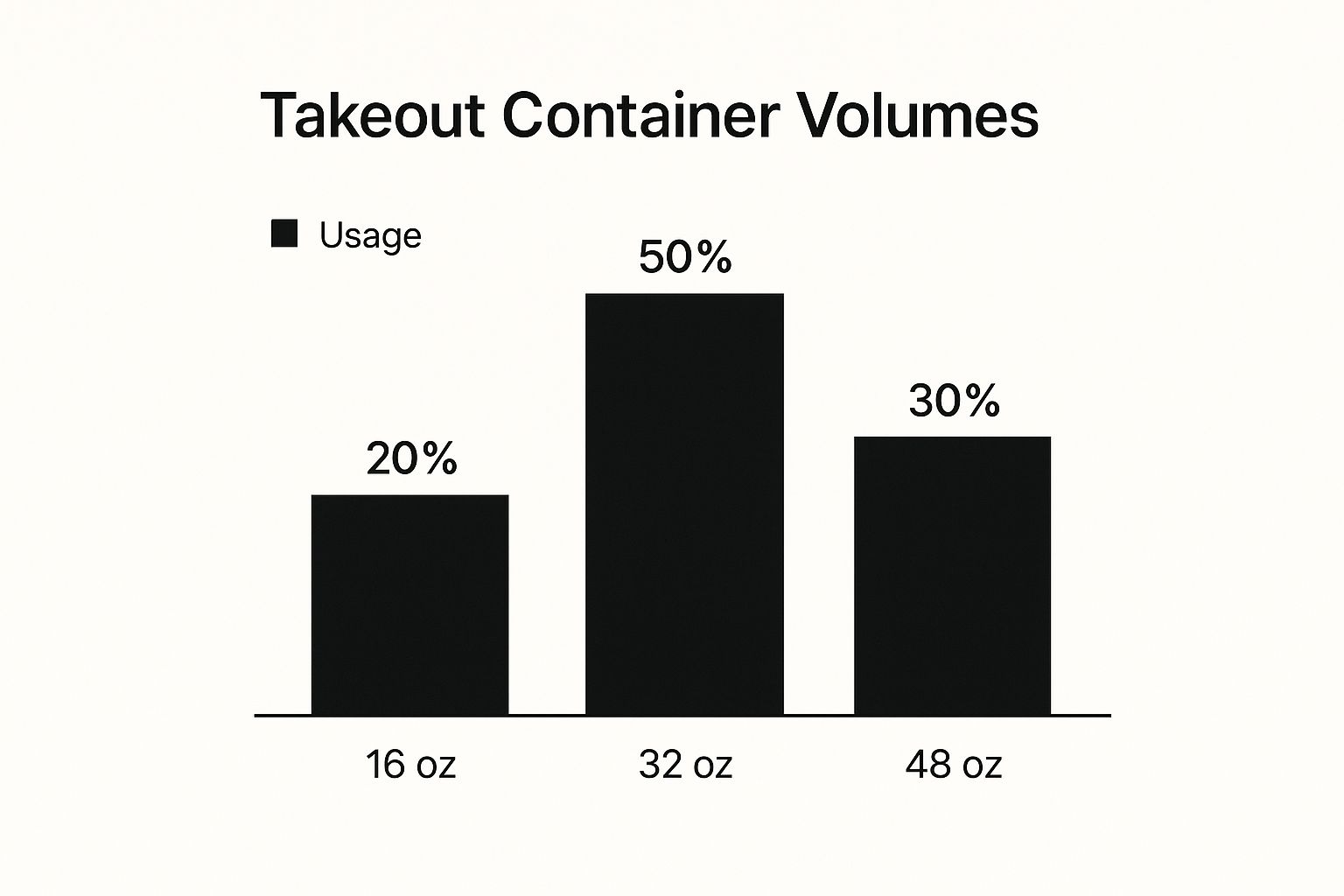

To help illustrate the distribution of container sizes, take a look at the infographic below:

The 32 oz container is the most popular, with 50% usage. The 48 oz container follows at 30%, and the 16 oz at 20%. This shows the demand for medium to large containers for takeout, reflecting the trend of individual entrees and shareable portions.

Why Dimensions Matter

The right container dimensions are vital for a positive customer experience. They prevent messy spills and keep food presentable, making a good first impression. They also help maintain serving temperature.

A shallow container will cool food faster than a deep one. This small detail can make a big difference in how much someone enjoys their meal. Happy customers are more likely to order again.

To further explore container sizes, let’s look at a comparison of standard takeout container sizes:

Standard Takeout Container Sizes Comparison

A comprehensive comparison of common takeout container dimensions with their typical uses and food capacity

| Container Size | Dimensions (inches) | Volume (oz) | Best For | Common Materials |

|---|---|---|---|---|

| Small | 4x4x2 (example) | 8-16 | Sauces, sides, small appetizers | Plastic, paperboard |

| Medium | 6x6x3 (example) | 24-32 | Individual entrees, salads, sandwiches | Plastic, paperboard, foam |

| Large | 8x8x4 (example) | 48+ | Family-style meals, combination platters | Plastic, foam, aluminum |

This table gives a general overview of common sizes. Note that dimensions and volumes can vary based on the manufacturer. It’s always a good idea to check with your supplier for precise measurements. Choosing the appropriate material also ensures the quality and integrity of the food during transport.

The Growing Takeout Market and Container Demand

The takeout industry is booming, and so is the demand for containers. The global takeout containers market is expected to reach USD 228.12 billion by 2030, with a CAGR of about 4.1% from 2024 to 2030.

This growth is fueled by the rise of food delivery services and quick-service restaurants. You can find more detailed statistics on the Maximize Market Research website. Choosing the right container size is key to meeting the needs of this expanding market. It ensures efficient use of resources and happy customers.

How Delivery Apps Are Reshaping Container Standards

The rise of delivery apps like Uber Eats and DoorDash has dramatically changed the takeout landscape. Takeout is no longer just a quick trip; it’s about meals traveling across town, sometimes taking 30 minutes or more to reach their destination. This shift in consumer behavior has placed new demands on takeout container sizes and their ability to maintain food quality over longer delivery times. Restaurants must now consider factors beyond simple portioning when choosing their containers.

Temperature Maintenance and the Delivery Dilemma

Maintaining optimal food temperature during delivery presents a significant challenge. A hot dish arriving cold, or a cold dish arriving warm, can quickly ruin the dining experience. Choosing the right takeout container size plays a vital role in temperature control.

Deeper containers often retain heat better than shallow ones. Insulated containers can help maintain the temperature of both hot and cold items. For example, a deep, insulated container is perfect for soups and stews, while a shallow container might suffice for a salad.

Customer Expectations and the Unboxing Experience

Customer expectations have changed alongside the delivery boom. The “unboxing experience” has become an extension of the restaurant itself.

A visually appealing container, securely sealed to prevent spills, and appropriately sized for the meal enhances the customer experience. A burger crammed into a too-small container or soup sloshing around in an oversized one creates a negative impression. This impacts customer satisfaction and potentially future orders, emphasizing the need for containers that both preserve food quality and elevate the overall dining experience.

Container Innovation in the Virtual Kitchen Age

The rise of virtual kitchens, also known as ghost kitchens, has further spurred container innovation. These delivery-only operations prioritize efficiency and often lead the way with new packaging approaches. They’ve been key in adopting multi-compartment containers and tamper-evident seals.

These innovations are now being embraced by traditional restaurants looking to improve their delivery services. You might be interested in: How to master takeout packaging design to show off your restaurant’s vibe.

The rapid growth of the online food delivery industry has significantly impacted takeout container sizes. By 2023, global takeout container demand was estimated at USD 40 billion, with projections to hit USD 65 billion by 2032. The growth of platforms like Uber Eats and DoorDash has fueled the need for containers that ensure safe, hygienic, and temperature-controlled food transport. Find more detailed statistics here. This highlights the increasing importance of selecting the appropriate takeout container size for delivery success.

Pairing Perfect Containers With Specific Food Types

The success of a takeout order depends heavily on the container. Choosing the right size can make the difference between a delightful and a disappointing meal. By considering factors like moisture content and serving temperature, restaurants can ensure their food arrives in perfect condition. This section explores how choosing the right container preserves food quality and improves the takeout experience.

Matching Containers to Food Characteristics

Different foods have different needs. A delicate pastry won’t have the same packaging requirements as a hearty curry. Moisture content is a key consideration. For instance, nobody wants a soggy salad. A container with ventilation or a separate compartment for dressing is crucial.

Serving temperature also plays a significant role. Hot foods need containers that retain heat and prevent leaks. Cold foods, on the other hand, require containers that maintain a cool temperature and prevent condensation. This guarantees the food arrives as intended.

Preventing Leaks and Maintaining Texture

Food texture is another critical factor. Crispy foods, like french fries or fried chicken, need containers that prevent them from getting soggy. Vented containers or those with absorbent liners can help maintain that satisfying crunch.

Saucy dishes and broths require leak-proof containers with secure lids. This not only prevents messy spills during delivery but also keeps the dish intact.

Expert Techniques for Optimal Presentation

Many restaurants use special techniques to keep food looking its best during transit. Compartmentalized containers are a great way to keep different parts of a dish separate, preventing flavors from mixing and maintaining an appealing presentation.

A bento box, for example, keeps rice, vegetables, and protein separate until the customer is ready to eat. This thoughtful approach enhances the dining experience and demonstrates attention to detail.

Container Dimensions: From Appetizers to Entrees

The size of the takeout container is paramount. Smaller appetizers might fit perfectly in a 4x4x2 inch container, holding approximately 8 oz. A larger entree might need a 6x6x3 inch container, which can hold 24-32 oz.

Some restaurants even use specialized containers for dishes that continue cooking after packaging, such as certain types of noodles. These containers often have ventilation to release steam, preventing the food from overcooking.

Real-World Examples of Strategic Sizing

Leading restaurants understand the importance of choosing the right container size. They tailor their container choices to specific dishes to ensure optimal quality and presentation. Some high-end restaurants even use custom-designed containers perfectly suited to their signature dishes. This personalized approach elevates the takeout experience and reinforces brand identity.

Optimal Container Sizes By Food Type

To help illustrate the relationship between food type and container size, the following table offers specific recommendations. It provides detailed guidance on choosing the optimal container based on food category and special considerations.

Optimal Container Sizes by Food Type

Detailed recommendations for container sizes based on specific food categories and special considerations

| Food Category | Recommended Container Size | Special Considerations | Alternative Options |

|---|---|---|---|

| Salads | Medium (24-32 oz) | Separate dressing container | Large (48 oz) for family-style salads |

| Soups/Stews | Medium or Large (depending on portion) | Leak-proof lid essential | Insulated containers for temperature maintenance |

| Fried Foods | Vented containers or those with absorbent liners | Ensure proper ventilation to prevent sogginess | Compartmentalized containers to separate dipping sauces |

| Noodles/Pasta | Containers with some ventilation | Prevent sticking and overcooking | Specialized containers designed for specific pasta types |

| Desserts | Small or medium containers (depending on portion size) | Secure lids to prevent spills | Compartmentalized containers for layered desserts or toppings |

By carefully selecting the right size takeout container for each dish, restaurants show a commitment to quality and enhance the customer experience. This attention to detail can greatly improve customer satisfaction and foster loyalty.

Global Perspectives on Takeout Container Dimensions

Takeout containers might seem like a simple necessity, but their sizes and designs vary significantly across the globe. These differences offer a fascinating glimpse into cultural norms surrounding food, portioning, and even dining rituals. Let’s explore how these seemingly mundane choices reflect deeper cultural values.

North America: The Land of Large Portions

North America, especially the United States, is well-known for its generous portion sizes. This preference is directly reflected in the size of its takeout containers. Fast-food chains, cloud kitchens, and fast-casual restaurants have significantly shaped the market, often opting for larger containers.

This trend impacts not just individual restaurants, but the entire supply chain, influencing packaging manufacturers and distributors. In fact, North America holds a dominant position in the takeaway container market, setting a precedent that often influences global standards. In 2025, the North American takeaway container market held significant value, contributing to a global market projected to grow from approximately USD 113.3 billion in 2025 to USD 159.9 billion by 2035, with a CAGR of 3.5%. You can learn more about this growing market here.

Europe: A Focus on Portion Control

European countries present a stark contrast to North American trends. They typically use smaller takeout containers, mirroring a cultural emphasis on portion control and minimizing food waste. European restaurants generally prioritize quality over quantity, reflecting a different dining philosophy. This focus on smaller portions also contributes to less packaging waste, aligning with broader sustainability efforts. Consequently, European takeout packaging often emphasizes compact and efficient designs.

Asia: Innovation in Multi-Compartment Solutions

Asian takeout containers frequently feature multiple compartments. This design reflects the cultural importance of balanced meals and the desire for distinct flavors within a single meal. The classic bento box is a perfect example, keeping different food elements separate, allowing for diverse flavors and textures without compromising individual components. This innovative approach to container design maximizes both food presentation and practicality.

Emerging Markets: Driving Packaging Innovation

Emerging markets are often leading the charge in packaging innovation. Driven by factors like cost-effectiveness and environmental concerns, these regions are exploring new materials and designs. They are often at the forefront of adopting biodegradable and compostable containers, demonstrating a growing awareness of sustainability in the food industry.

This focus on eco-friendly solutions positions these markets as key players in shaping the future of takeout packaging. Furthermore, these regions frequently prioritize space-efficient designs and containers optimized for shared meals, reflecting the cultural emphasis on communal dining experiences in many emerging markets.

Eco-Friendly Options Across the Size Spectrum

Sustainability is a growing concern for consumers. This makes eco-friendly takeout container sizes a smart move for restaurants. Thankfully, today’s options are better than ever. This section explores how restaurants can make eco-conscious choices for their takeout packaging without compromising quality.

Right-Sizing for a Greener Footprint

Right-sizing is essential for minimizing waste. Choosing the right size container for each item reduces unnecessary material usage. For instance, a small container for a side dish instead of a large one conserves resources. This approach benefits the environment and can even cut costs.

Plant-Based Powerhouses: Material Selection

Different plant-based materials offer unique advantages. Bagasse, derived from sugarcane, is a strong, compostable choice. Bamboo is rapidly renewable, durable, and visually appealing. However, it’s typically more expensive.

PLA (Polylactic Acid), made from cornstarch, is compostable in the right conditions. It’s a good option for cold items but less heat-resistant. Understanding these differences allows restaurants to choose the optimal material for their needs. Learn more in our article about eco-friendly takeout containers.

Performance Comparison: Sustainable vs. Traditional

Comparing the performance of sustainable and traditional materials is vital. Moisture resistance, heat retention, and structural integrity are all key factors.

Some plant-based options excel in moisture resistance but may not retain heat as well as traditional plastic. Careful selection based on food type and delivery distance is important. The container size also matters, as larger containers may need stronger materials.

Transitioning to Sustainable Packaging

Switching to sustainable packaging can be a smooth process. Start by identifying your most used takeout container sizes. Then, explore eco-friendly alternatives in those sizes. A small-scale trial with specific menu items allows for feedback before a full transition.

Size Recommendations by Menu Category

Here’s a general guide for choosing sustainable takeout container sizes:

- Small containers (8-12 oz): Sauces, dips, small sides. Bagasse or PLA are good choices.

- Medium containers (16-24 oz): Individual entrees, salads, sandwiches. Bagasse, bamboo, or molded fiber offer good performance.

- Large containers (32+ oz): Family meals, large portions. Molded fiber or sturdy bamboo are recommended.

These are guidelines. The ideal choice depends on the food and your restaurant’s needs.

By considering materials, performance, and menu specifics, restaurants can confidently choose eco-friendly takeout container sizes. This move towards sustainability benefits the planet and strengthens a restaurant’s brand image with eco-conscious customers.

The Financial Impact of Smart Container Sizing

Takeout container sizes have a surprising impact on a restaurant’s finances. While it might seem like a minor detail, choosing the correct container can boost profits, while the wrong one can negatively affect them. This section explores the financial aspects of takeout packaging and how strategic container choices influence a restaurant’s bottom line.

Right-Sizing: Reducing Costs and Improving Customer Satisfaction

Right-sizing, which means selecting the appropriate container size for each dish, offers significant cost savings. Using smaller containers for smaller portions reduces material costs and shipping weight. This efficiency directly increases profit margins.

Right-sizing also improves the customer experience. Customers appreciate receiving the right amount of food in a properly sized container, leading to positive reviews and increased customer loyalty. This, in turn, generates repeat business. For further information on selecting the right containers, check out this helpful resource: How to choose disposable food containers.

Hidden Expenses of Poorly Chosen Containers

Choosing the wrong containers can lead to hidden expenses that significantly affect profitability. Oversized containers increase both material and shipping costs. They also raise the risk of spills during delivery, resulting in remakes, refunds, and lost customers.

Conversely, undersized containers can make portions appear smaller than they are, leading to customer dissatisfaction and negative reviews. This can damage a restaurant’s reputation and discourage future orders.

Cost Comparisons Across Container Sizes and Materials

The material of the container also plays a role in cost. While styrofoam containers are often the most affordable option, they are not environmentally friendly and can negatively affect a restaurant’s image. Eco-friendly options like bagasse or bamboo cost more but align with the increasing consumer demand for sustainable practices.

The table below compares the costs of different container sizes and materials:

| Container Size | Material | Approximate Cost per Unit |

|---|---|---|

| Small (8oz) | Styrofoam | $0.10 |

| Small (8oz) | Bagasse | $0.25 |

| Medium (16oz) | Styrofoam | $0.15 |

| Medium (16oz) | Bagasse | $0.35 |

| Large (32oz) | Styrofoam | $0.20 |

| Large (32oz) | Bagasse | $0.50 |

Optimizing Container Inventory and Reducing Storage Space

Effective container management optimizes inventory and minimizes storage requirements. Standardizing container sizes reduces the variety of containers a restaurant needs, which simplifies both ordering and storage. This also increases efficiency during packing and reduces the chances of using the wrong container size.

Standardizing sizes can also lead to better pricing negotiations with suppliers. Larger orders of fewer container types can unlock volume discounts.

Premium vs. Standard: When to Splurge and When to Save

The decision between premium and standard containers depends on their intended use. Premium containers enhance presentation and are ideal for high-value dishes or special occasions. Standard containers are a suitable choice for everyday takeout orders.

Understanding your target audience and the type of food you serve will help you decide when to invest in premium packaging and when standard options are sufficient.

Ready to improve your takeout packaging and boost your profits? Explore a wide variety of high-quality, cost-effective takeout containers at MrTakeOutBags.com. They offer various sizes, materials, and customization options to meet your specific business needs.