The Strategic Value of Cupcake Boxes Wholesale

Savvy bakery owners know that cupcake boxes wholesale are more than just a necessary expense. They’re a smart investment that can significantly impact a business, from small local bakeries to larger operations. This shift in thinking is reshaping the cupcake box market. Let’s explore why.

Enhancing Brand Perception Through Packaging

Consider the cupcake box the first tangible interaction a customer has with your brand. A flimsy, generic box can lessen the perceived value of your cupcakes. On the other hand, a sturdy, attractive box enhances the whole experience, conveying quality and a professional touch. This is particularly important with the growth of online food delivery, where the packaging often represents the entire customer experience.

Capitalizing on Market Trends with Wholesale Strategies

Customer expectations are evolving. Sustainability and distinctive brand experiences are increasingly important. Buying cupcake boxes wholesale allows bakeries to meet these demands effectively. Bulk purchases unlock more customization choices, letting bakeries create branded packaging that resonates with their target audience. Wholesale also often opens doors to a wider selection of eco-friendly materials, aligning with those important evolving consumer values.

The Economic Advantage of Buying in Bulk

The growing popularity of cupcakes, paired with the expansion of bakeries globally, fuels strong demand for cupcake boxes. The worldwide cupcake box market is estimated to be worth about USD 2.5 billion in 2025, with projections of a steady 5% Compound Annual Growth Rate (CAGR) from 2025 to 2033. This growth stems from factors like the demand for visually appealing desserts and the rise of online food delivery platforms that require secure packaging. This expanding market highlights the need for a strategic packaging approach, and cupcake boxes wholesale offer a clear financial edge.

Turning Necessary Expenses into Strategic Advantages

Securing cupcake boxes wholesale empowers bakeries in negotiations with suppliers. This often results in lower per-unit costs and better profit margins. These cost savings allow for investment in customization and higher-quality materials, further boosting brand perception. Buying cupcake boxes in bulk isn’t just about saving money; it’s about building a win-win situation. Reduced expenses directly contribute to greater brand value and stronger customer loyalty, changing a necessary expense into a strategic advantage for sustained business growth.

Embracing Sustainable Cupcake Boxes at Scale

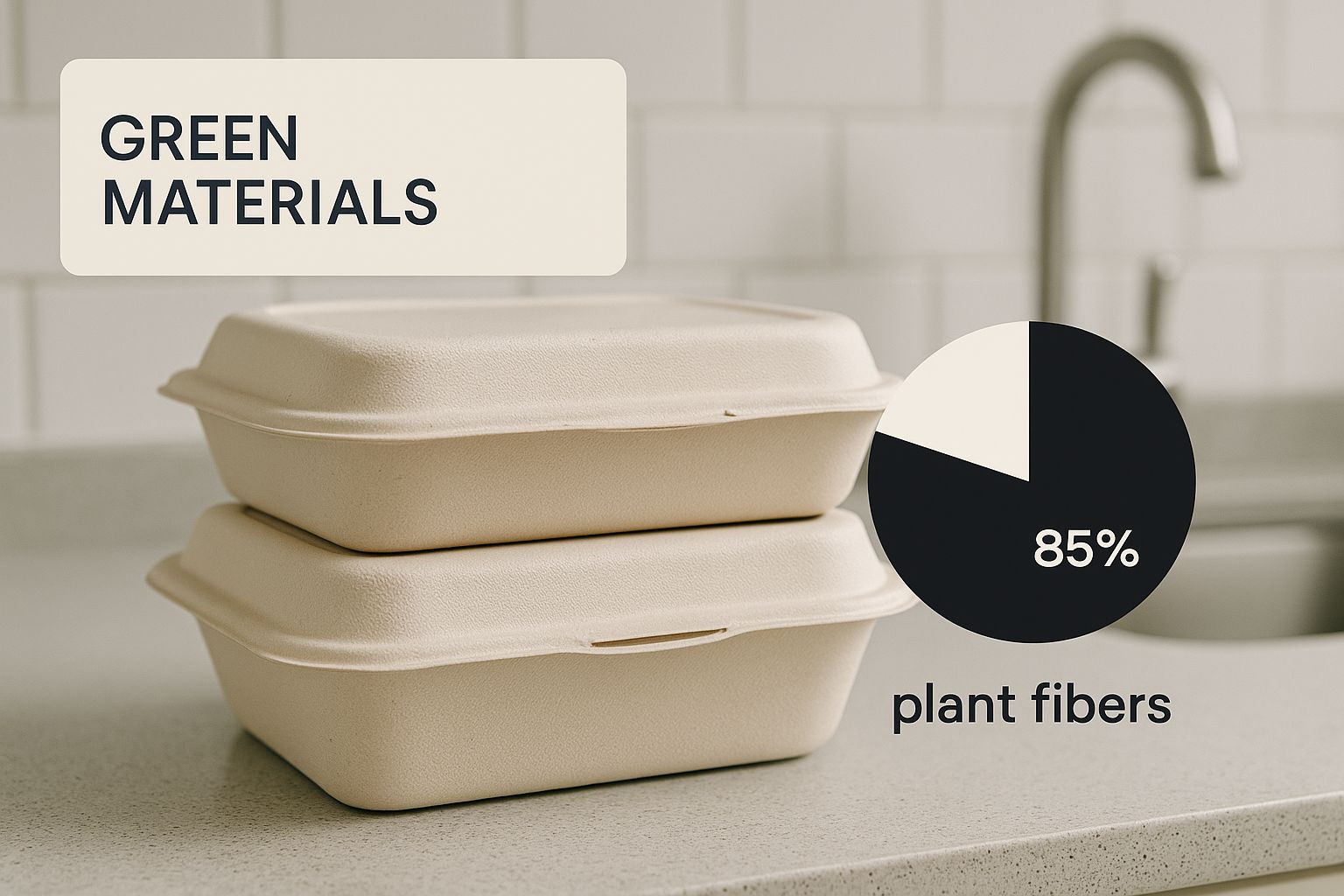

Sustainability isn’t just a trend anymore; it’s a value that many customers hold dear. This shift offers bakeries a chance to boost their brand image and reduce their environmental impact by using cupcake boxes wholesale. But going green with packaging requires careful thought about how the materials perform and how customers see them.

Balancing Performance and Sustainability in Cupcake Box Materials

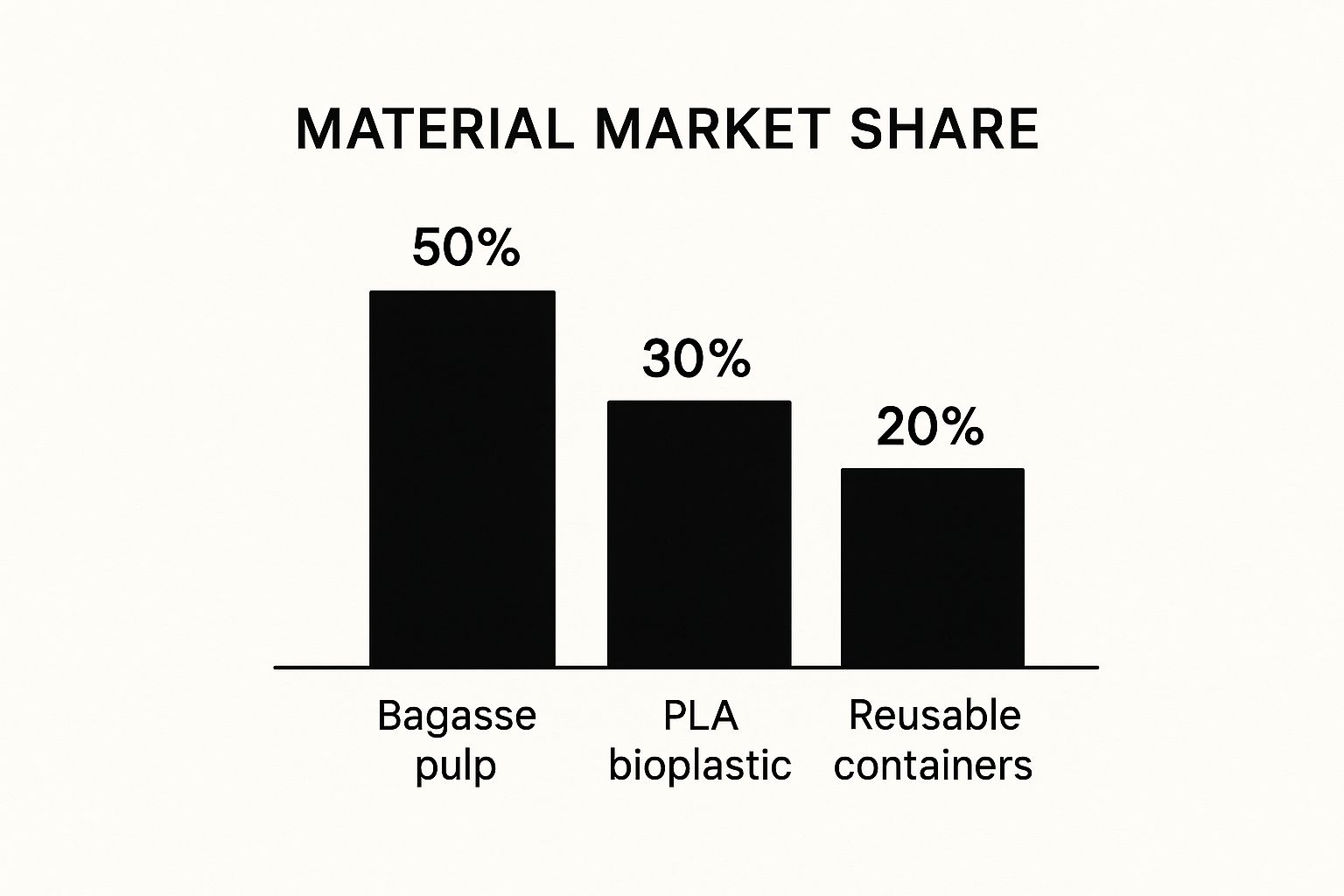

Many bakeries are switching to sustainable materials for their cupcake boxes. Popular options include recycled cardboard, biodegradable choices like bagasse (sugarcane fiber), and compostable materials. Recycled cardboard is a readily available and budget-friendly choice, while bagasse offers a unique texture and a strong sustainability story.

However, not all eco-friendly materials are created equal. Some compostable options may not be strong enough for stacking or might not resist moisture well, which is important for keeping cupcakes fresh.

Communicating Sustainability Efforts to Customers

Switching to sustainable materials is just the first step; telling your customers about it is equally vital. Transparency is key. Labeling boxes clearly with details about the materials and what can be done with them after use, like “100% Recycled Cardboard” or “Compostable Bagasse,” helps customers make choices that fit their values.

This open approach builds trust with your customers and shows your commitment to the environment. It creates a stronger connection that goes beyond a single purchase, fostering loyalty and repeat business.

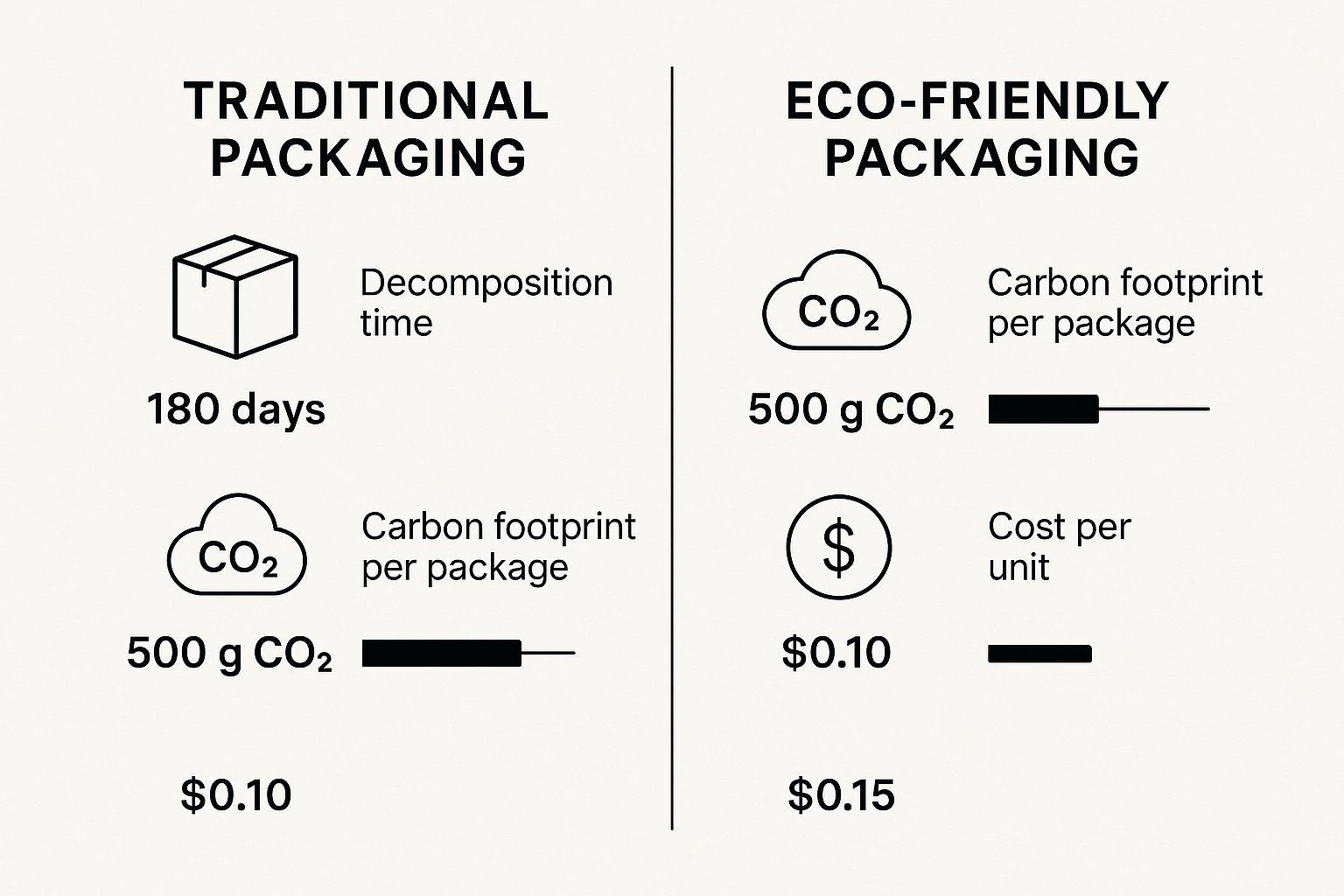

The Financial Landscape of Sustainable Cupcake Boxes Wholesale

The price of cupcake boxes wholesale depends on the material, the size of the order, and any extra features. While eco-friendly options can sometimes cost a bit more upfront, the long-term advantages can make them a worthwhile investment.

The global cupcake box market was valued at approximately USD 0.251 billion in 2023 and is projected to grow at a CAGR of about 5.2% from 2023 to 2030, according to Cognitive Market Research. This increasing demand for cupcake packaging, fueled by consumer preferences and gifting trends, presents opportunities to save money by buying in bulk.

Buying wholesale can lower the cost per box, making sustainable packaging a practical choice for businesses of all sizes. This market growth highlights the importance of a strategic, long-term plan for sourcing packaging.

Identifying Eco-Friendly Features that Resonate with Customers

Knowing what matters most to your target audience is crucial for making the most of your investment in sustainable packaging. Some customers prioritize recyclability, while others might prefer compostability or materials from sustainably managed forests.

Customer surveys and analyzing buying habits can reveal which eco-friendly features truly influence purchasing decisions. This information can guide your packaging choices, helping you focus on the features that make the biggest difference. This targeted approach reduces unnecessary costs while building your brand’s authenticity and strengthening customer relationships.

Matching Cupcake Boxes to Your Business Reality

Not all bakeries are created equal when it comes to packaging needs. Choosing the right cupcake boxes wholesale hinges on several factors, from your production volume to the specific types of cupcakes you sell. This section will guide you to the perfect fit for your business.

Structural Integrity and Stackability: Protecting Your Products

Cupcakes are delicate creations. Your boxes need the strength to protect them during transport and storage. Structural integrity is paramount, especially for high-volume orders or stacked boxes. Features like reinforced corners and sturdy inserts prevent crushing and ensure your cupcakes arrive looking pristine.

Stackability is also essential for efficient storage and display. Boxes designed to stack securely prevent toppling and maximize your valuable space.

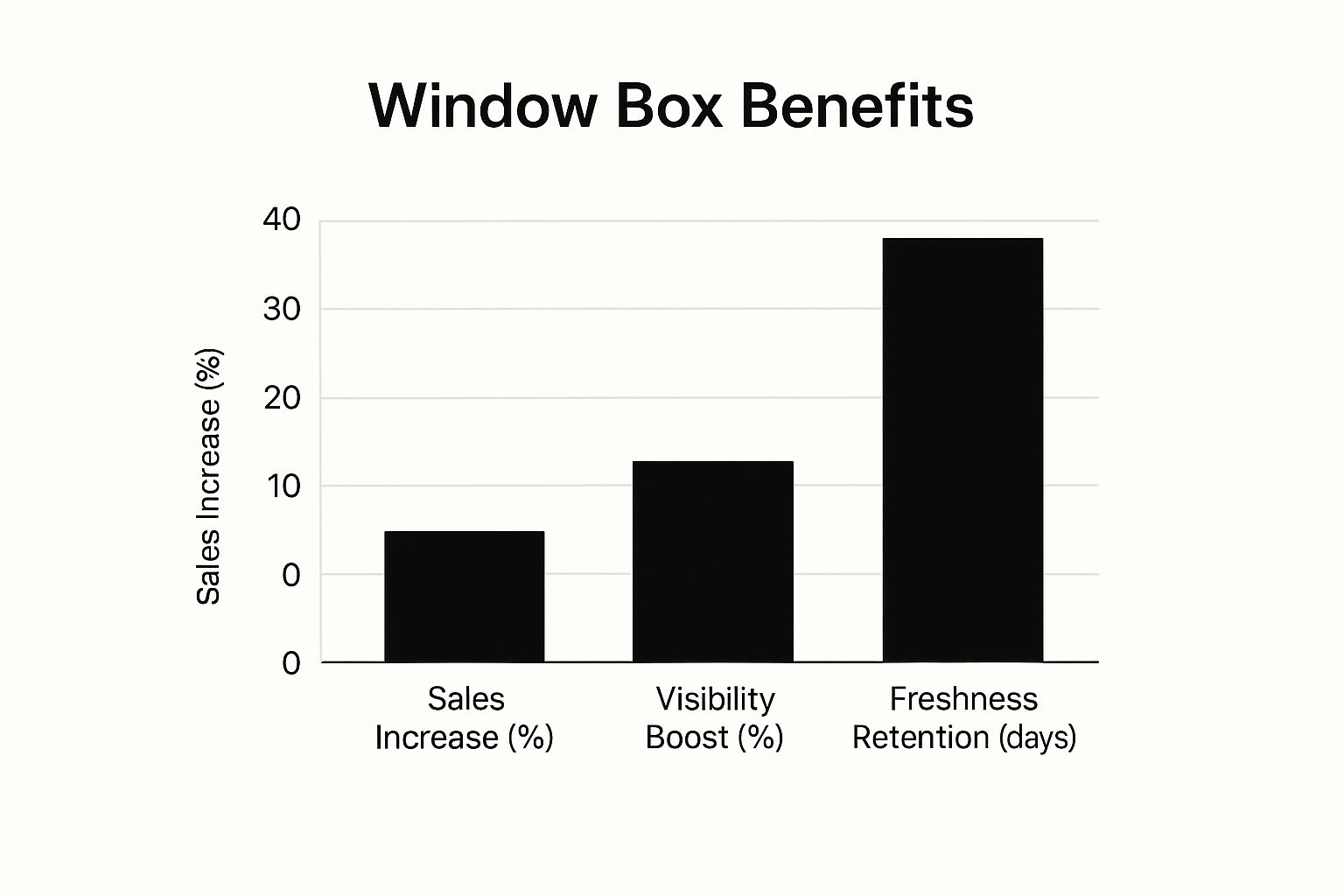

Moisture Resistance and Display Quality: The Freshness Factor

Moisture resistance is crucial for maintaining that just-baked freshness. Look for boxes made with materials that repel grease and moisture, keeping your cupcakes looking and tasting delicious.

Display quality matters, too, especially in retail settings. Attractive boxes with windows or clear lids showcase your beautiful cupcakes and entice customers.

Matching Box Design to Product and Business Model

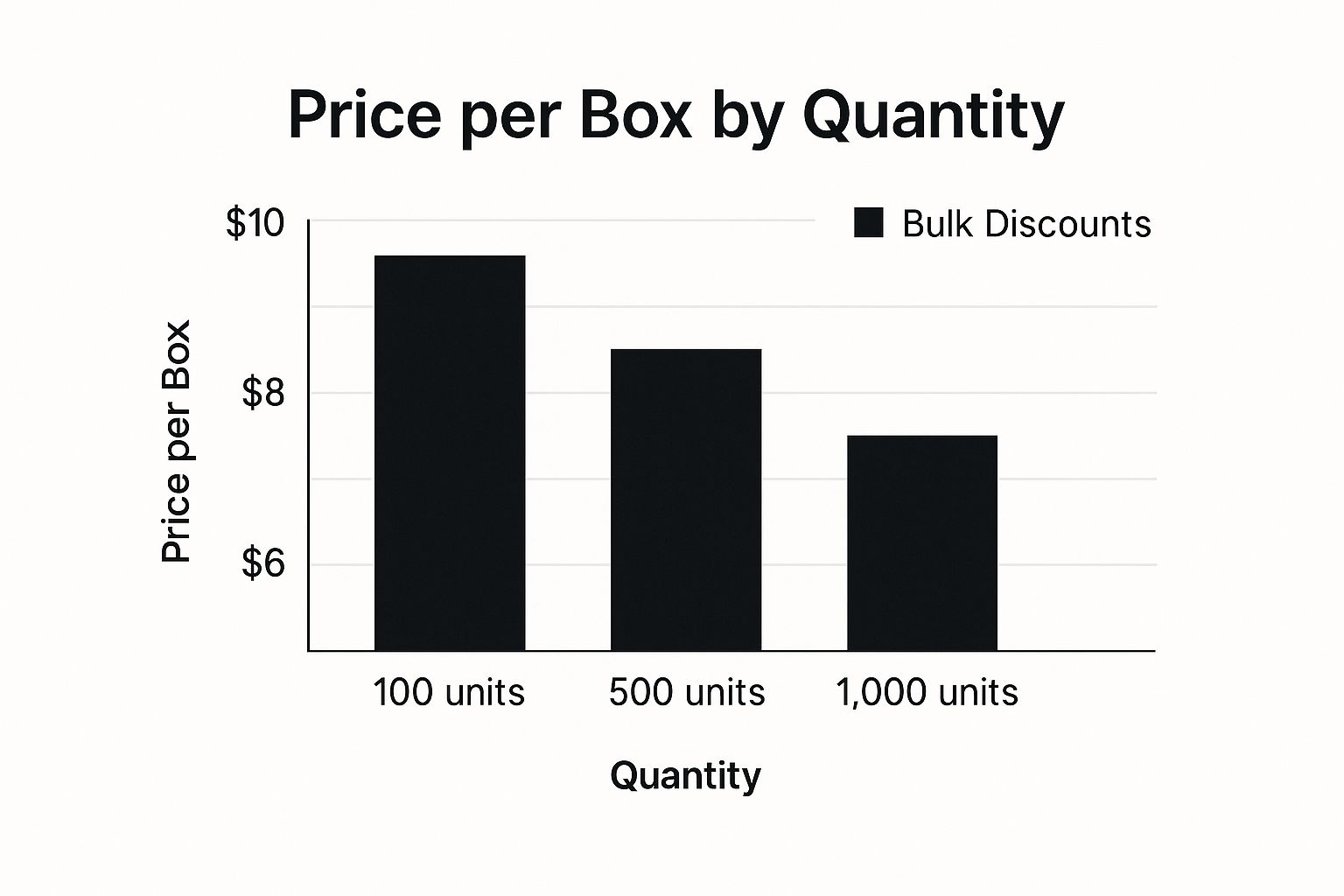

The right box depends on what you’re selling and your sales method. High-volume bakeries might opt for simple, cost-effective boxes. However, artisanal cupcake makers might prioritize premium boxes reflecting their unique brand. The infographic below visualizes the impact of wholesale volumes on price, comparing costs at 100, 500, and 1,000 units.

As you can see, buying larger quantities of cupcake boxes leads to significant savings per unit. This underscores the financial benefits of a wholesale approach.

Calculating Your Needs and Avoiding Overordering

Accurately calculating your cupcake box needs is essential to prevent overstocking and waste. Consider your average weekly sales, upcoming special events, and typical supplier lead times. A small safety stock is wise, but avoid excessive overordering.

Evaluating Features and Costs: Finding the Right Balance

Some premium features might not be worth the added cost. For instance, custom-printed boxes, while visually appealing, might be unnecessary for some businesses. Evaluate features based on their impact on customer experience and operational efficiency, focusing on those that provide the best value.

To help you choose the right box, we’ve compiled a comparison table:

Cupcake Box Types Comparison for Wholesale Buyers

| Box Type | Material | Typical Cost Range | Best For | Durability | Eco-Friendly Rating |

|---|---|---|---|---|---|

| Single Cupcake Box | Cardboard | $0.20 – $0.50/unit | Individual sales, gifts | Moderate | Good (Recyclable) |

| 4-Cupcake Box | Cardboard/Paperboard | $0.50 – $1.20/unit | Small gatherings, deliveries | Good | Good (Recyclable) |

| 6-Cupcake Box | Cardboard/Paperboard | $0.75 – $1.50/unit | Parties, events | Good | Good (Recyclable) |

| 12-Cupcake Box | Corrugated Cardboard | $1.00 – $2.50/unit | Larger events, catering | High | Good (Recyclable) |

| Windowed Cupcake Box | Cardboard with a PET window | $0.30 – $0.70/unit (single) | Retail displays, showcasing designs | Moderate | Fair (Window may need to be removed for recycling) |

Maximizing ROI on Wholesale Packaging Investments

Smart packaging choices are about more than just the initial cost of cupcake boxes wholesale. They have a ripple effect on your bakery’s overall financial health. This section guides you through optimizing your packaging spend for greater profitability. We’ll cover balancing bulk discounts with storage costs and the impact of smart ordering on your cash flow.

Calculating Your Optimal Order Quantity

Finding the sweet spot for ordering cupcake boxes wholesale is a balancing act. Order too few, and you miss out on bulk discounts and risk running short during peak periods. Order too many, and you tie up capital and face storage headaches.

A smaller bakery with limited space might opt for frequent, smaller orders. A larger bakery with ample warehousing could leverage bulk buying for significant savings.

Negotiation Tactics and Hidden Fees to Watch For

Negotiating with suppliers is essential. Don’t hesitate to ask for better pricing, especially on large cupcake boxes wholesale orders. Even a small percentage discount, like 5%, on a large order can add up significantly.

Also, be mindful of hidden fees. Delivery charges or plate setup fees for custom printing can erode your margins. Keep an eye out for these seemingly small expenses that can quickly accumulate.

Inventory Management Best Practices

Effective inventory management is key to maximizing your cupcake boxes wholesale ROI. A robust inventory tracking system helps prevent both stockouts and waste. Understanding your supplier lead times is crucial for accurate forecasting and a smooth ordering schedule. This prevents last-minute scrambles and keeps your operations running smoothly.

Tracking Packaging Costs as a Percentage of Product Cost

Successful bakeries keep a close watch on packaging costs, often tracking them as a percentage of total product cost. This provides a clear picture of how packaging impacts profitability. It also allows for easier comparison of different packaging options and their overall cost implications.

For example, the cake box market, closely related to cupcake boxes, is projected to reach USD 712.6 million by 2035, growing at a CAGR of 4.5% from its USD 458.9 million value in 2025. Bakeries and confectioneries represent roughly 50% of this market.

Optimizing Your Ordering Frequency

How often should you order cupcake boxes wholesale? The answer depends on your sales patterns and supplier lead times. Balancing order frequency with volume discounts and storage capacity is key.

A consistent ordering schedule streamlines operations, allowing you to accurately forecast packaging needs and negotiate effectively with suppliers.

To understand how volume affects pricing, let’s look at a typical pricing structure:

Wholesale Cupcake Box Pricing Structure

| Order Volume | Price Per Unit | Savings vs. Retail | Recommended For | Typical Lead Time |

|---|---|---|---|---|

| 100-500 | $2.50 | 10% | Small bakeries, startups | 1-2 weeks |

| 501-1000 | $2.00 | 25% | Medium-sized bakeries, growing businesses | 2-3 weeks |

| 1001-5000 | $1.50 | 40% | Large bakeries, high-volume production | 3-4 weeks |

| 5000+ | $1.00 | 60% | Wholesale distributors, large-scale events | 4-6 weeks |

By strategically managing your wholesale packaging investments, you can ensure your cupcake boxes contribute positively to your business success.

Building Relationships With Reliable Suppliers

A reliable supplier of cupcake boxes wholesale is essential for any successful bakery. This section explores how to find, vet, and nurture these crucial partnerships, transforming a potentially stressful process into a strategic advantage. We’ll cover identifying dependable suppliers and avoiding potential pitfalls, ensuring your cupcake boxes are always readily available.

Identifying the Red Flags of Unreliable Vendors

Finding the right supplier is just as important as avoiding the wrong ones. Unreliable vendors can disrupt your operations and negatively impact your brand. Some key warning signs include inconsistent communication, frequent missed deadlines, and a lack of transparency regarding pricing and lead times.

For instance, a supplier consistently delaying shipments or providing vague responses about order status is a major red flag. These issues can cause stock shortages, lost opportunities, and unhappy customers.

Be wary of suppliers reluctant to provide samples or with a history of quality control issues. Inspecting samples lets you evaluate the quality of the cupcake boxes wholesale firsthand, potentially preventing costly mistakes.

Recognizing the Hallmarks of Excellent Suppliers

Great suppliers are more than just box providers; they’re partners invested in your success. They understand your business needs and proactively address them. Clear and consistent communication, a proven track record of on-time delivery, and a willingness to accommodate custom orders and special requests are all key indicators of a strong supplier.

Excellent suppliers also offer transparent pricing, detailed product specifications, and accessible customer support. This open communication builds trust and facilitates a smooth, efficient ordering process. They maintain robust quality control procedures and provide solutions for resolving any issues that may occur.

Manufacturer Vs. Distributor: Weighing the Pros and Cons

Choosing between working directly with a manufacturer or a distributor is a key decision. Manufacturers often offer lower prices for cupcake boxes wholesale, particularly for large orders. However, they might require higher minimum order quantities and longer lead times.

Distributors, conversely, typically offer greater flexibility with smaller order sizes and quicker delivery. Their per-unit prices might be slightly higher. The best choice depends on your specific business requirements and order volume. A smaller bakery might benefit from a distributor’s flexibility, while a larger operation could leverage the cost savings of working directly with a manufacturer.

Evaluating Suppliers Beyond Initial Pricing

While price is important, it shouldn’t be the only factor when selecting a cupcake boxes wholesale supplier. Other critical considerations include consistent quality, problem-solving processes, and communication patterns. For example, how does the supplier handle damaged goods or incorrect orders? A supplier with a clear and efficient problem-resolution process can save you valuable time and minimize headaches.

Successful bakeries evaluate these aspects by requesting references, checking online reviews, and thoroughly interviewing prospective suppliers. This due diligence allows you to gain a comprehensive understanding of the supplier’s reliability and customer service.

Navigating International Sourcing and Lead Times

International sourcing can provide significant cost advantages for cupcake boxes wholesale. However, it also introduces complexities such as extended lead times, potential communication barriers, and currency fluctuations. Understanding these factors and planning accordingly is crucial. Setting realistic lead time expectations is vital to avoid stockouts.

Building Mutually Beneficial Relationships

Cultivating strong relationships with your suppliers is a long-term investment. Open communication, consistent feedback, and a collaborative approach foster mutual understanding and benefit both parties. This strong partnership can help you weather supply chain disruptions and maintain a consistent flow of high-quality cupcake boxes wholesale, contributing to the seamless operation of your bakery.

Transforming Boxes Into Branded Experiences

Your cupcake boxes are more than just containers; they’re a powerful marketing tool. This section explores how cupcake boxes wholesale can be transformed into branded experiences, from simple logo placements to elaborate custom designs. We’ll delve into the return on investment (ROI) of various customization options, helping you distinguish worthwhile investments from unnecessary expenditures. We’ll also uncover how top bakeries are turning their packaging into shareable moments on social media platforms like Instagram, fostering organic marketing and cultivating loyal customers.

Understanding the Spectrum of Customization

Customizing cupcake boxes wholesale opens a world of possibilities. A simple, elegant logo can significantly elevate your brand’s presence. Adding a brand color or a unique pattern can further enhance the visual appeal.

For more advanced branding, consider custom inserts, ribbons, or stickers. These small touches create a memorable unboxing experience and contribute to a premium feel.

Printing Methods and Material Considerations

Different printing methods offer varying levels of quality and cost-effectiveness. Offset printing is ideal for large quantities of cupcake boxes wholesale, providing high-quality results at a competitive price per unit. Digital printing, on the other hand, is better suited for smaller runs or when customization is a priority.

Understanding material limitations is also essential. Certain materials might not be suitable for all printing methods. For instance, intricate designs might not be feasible on certain recycled materials. Careful consideration of these factors will ensure your vision translates seamlessly to the finished product.

Design Specifications and Print-Ready Files

Working with designers and preparing print-ready files can seem daunting, but a few key steps can streamline the process. Providing clear design specifications, including dimensions, color codes, and file formats, is crucial for accurate reproduction. Vector files, such as .ai or .eps, are generally preferred for their scalability and crisp printing results.

Collaborating closely with your designer and printer can minimize potential issues, ensuring the final product aligns perfectly with your vision. This upfront investment in clear communication pays off in the long run, saving both time and resources.

Creating an Unboxing Experience

The moment a customer opens your cupcake box is an opportunity to reinforce your brand and foster lasting positive impressions. Consider the elements that create a memorable unboxing:

- Tissue paper or crinkle cut filler: Adds a touch of elegance and protects the cupcakes.

- Custom stickers or labels: Reinforce your logo and add a personalized message.

- Thank you cards or promotional inserts: Express gratitude and promote other offerings.

These small details can transform a simple transaction into an experience, building stronger connections with your customers and promoting loyalty.

Measuring the ROI of Customization

Not all customization is created equal in terms of ROI. While an elaborate, fully customized box might be stunning, it might not be financially viable for all businesses. Analyze the potential return of each customization element. A small, well-placed logo might deliver a higher ROI than a complex, multi-color print. Track customer feedback and sales data to measure the impact of different customization choices.

Instagram-Worthy Packaging and Organic Marketing

Packaging plays a crucial role in organic marketing. Eye-catching cupcake boxes wholesale become shareable content, boosting brand visibility and driving organic reach. This user-generated content is invaluable, creating authentic engagement and spreading awareness.

Consider how your box design can encourage social sharing, from unique colors and patterns to interactive elements that invite customers to capture and share their unboxing experience. Creating a branded experience with your cupcake boxes is an investment that extends far beyond the initial purchase. It’s a strategic move that strengthens your brand identity, enhances the customer experience, and ultimately boosts your bottom line.

Visit MrTakeOutBags.com for a wide selection of high-quality cupcake boxes wholesale and custom packaging solutions to elevate your brand.