The Strategic Advantage of Cookie Boxes Bulk Purchasing

Smart packaging choices are crucial for a bakery’s bottom line. Bulk buying of cookie boxes, in particular, offers several advantages that can boost profits and contribute to overall business expansion. Many bakery owners see a 15-25% increase in profit margins after switching to a bulk-buying strategy for their packaging needs. This is because bulk purchases directly reduce your per-unit cost.

Optimizing Inventory and Reducing Costs

A primary benefit of buying cookie boxes in bulk is the improved control over inventory management. Purchasing larger quantities helps bakeries avoid last-minute supply shortages that could lead to production delays and missed sales opportunities. For better management of your bulk cookie box inventory, consider improving your inventory turnover. Bulk purchasing also usually translates to significant cost savings thanks to volume discounts. These savings free up resources for other essential business areas, such as sourcing premium ingredients or investing in marketing campaigns.

Scaling Your Business With Consistent Packaging

Consistent, high-quality packaging is essential for business growth, especially during busy periods or seasonal peaks. A readily available supply of cookie boxes allows bakeries to meet increased customer demand without compromising on presentation. This consistency strengthens brand recognition and leads to a better customer experience. Maintaining a steady packaging supply ensures your product always looks its best, no matter the order size.

Growth of the Cookie Market

The global cookie market, including bulk cookie boxes, has experienced remarkable growth. In 2022, the market reached $37.8 billion, climbing to $41.6 billion by 2024. Projections estimate further growth to $62.2 billion by 2032, with a CAGR of approximately 5.2%. This expansion is driven by consumer demand for easy and diverse snacking options. This growing demand highlights the importance of a reliable packaging supply chain.

Maintaining Pricing Power and Competitive Advantage

Beyond direct cost savings, bulk purchasing of cookie boxes provides a strategic edge during supply chain disruptions. Securing large quantities of packaging ahead of time helps mitigate the impact of price increases and material shortages. This proactive approach helps bakeries maintain their pricing power and stay competitive even in uncertain market conditions, boosting business resilience and protecting profits. Learn more about building your brand through packaging. Strategically managing your packaging supply creates a consistent brand experience and prevents disruptions that could harm customer perception.

Beyond Basics: Cookie Boxes Bulk Options That Impress

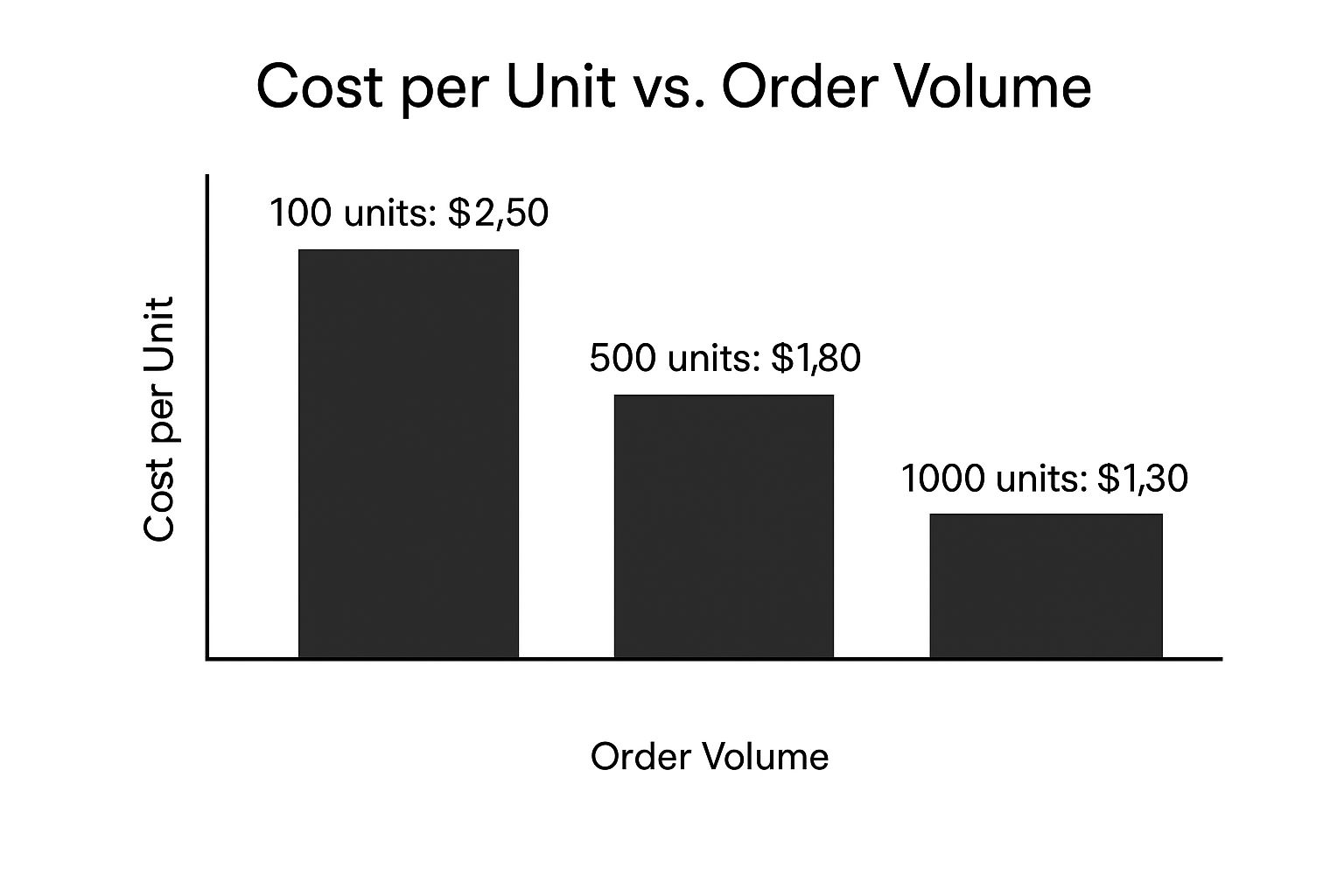

The infographic above illustrates how order volume affects the cost of your cookie boxes. Notice how the cost per unit drops significantly as your order volume increases. This highlights the potential savings you can unlock by buying your cookie boxes in bulk.

Material Matters: Choosing the Right Cookie Box

Your cookie box is more than just a container; it’s a key part of the presentation. The material you choose affects everything from shipping durability to how customers perceive your brand. Making the right choice is essential for success. Kraft boxes offer a popular, cost-effective option with a rustic, natural appeal. However, Kraft may not project the premium image some brands aim for.

- Kraft: Economical, readily available, and recyclable, Kraft provides a classic, natural aesthetic.

- Cardboard: Strong and customizable, cardboard offers excellent protection during shipping and is perfect for high-quality printing.

- Corrugated Cardboard: If you’re shipping delicate cookies, corrugated cardboard provides superior protection with its added thickness and cushioning.

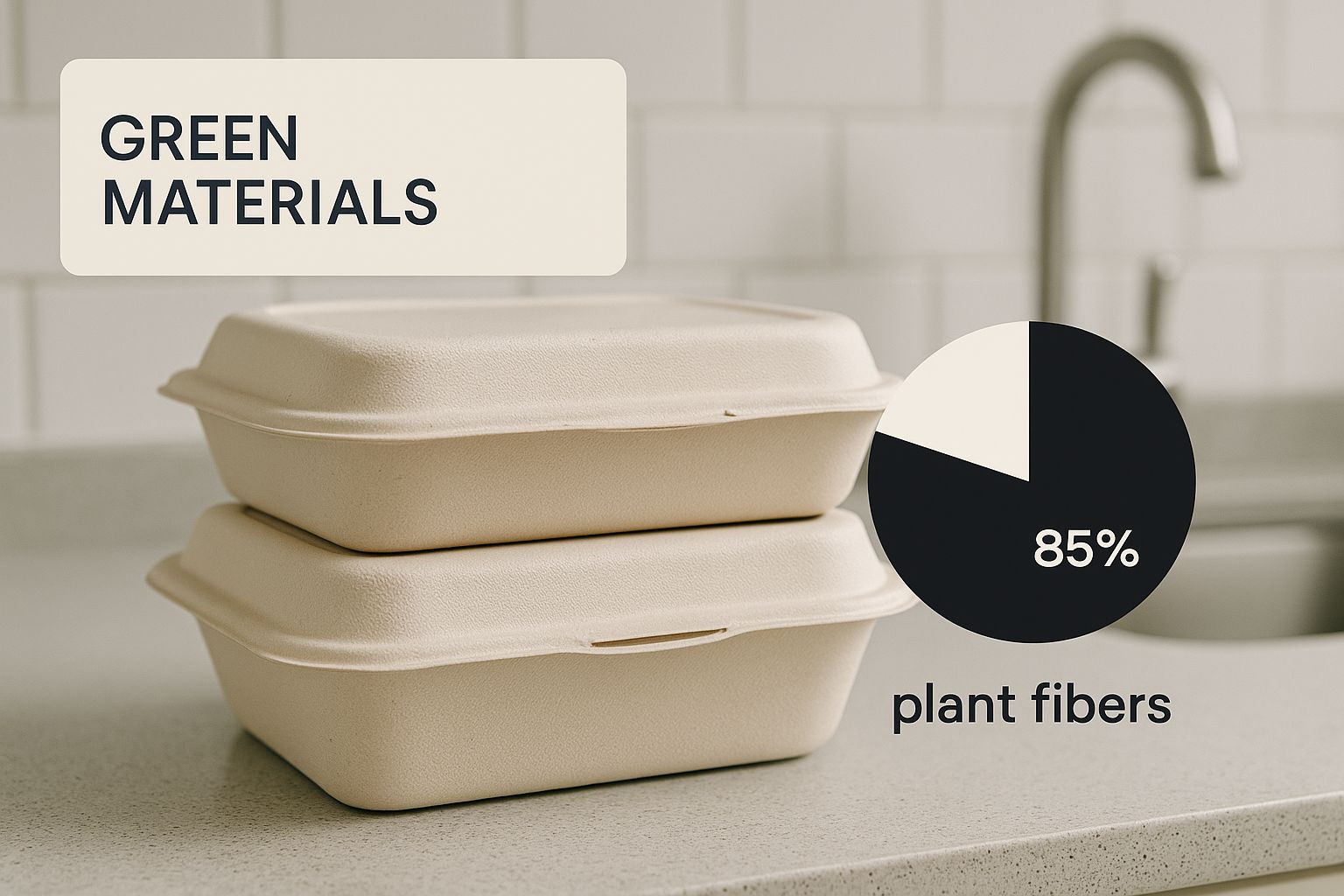

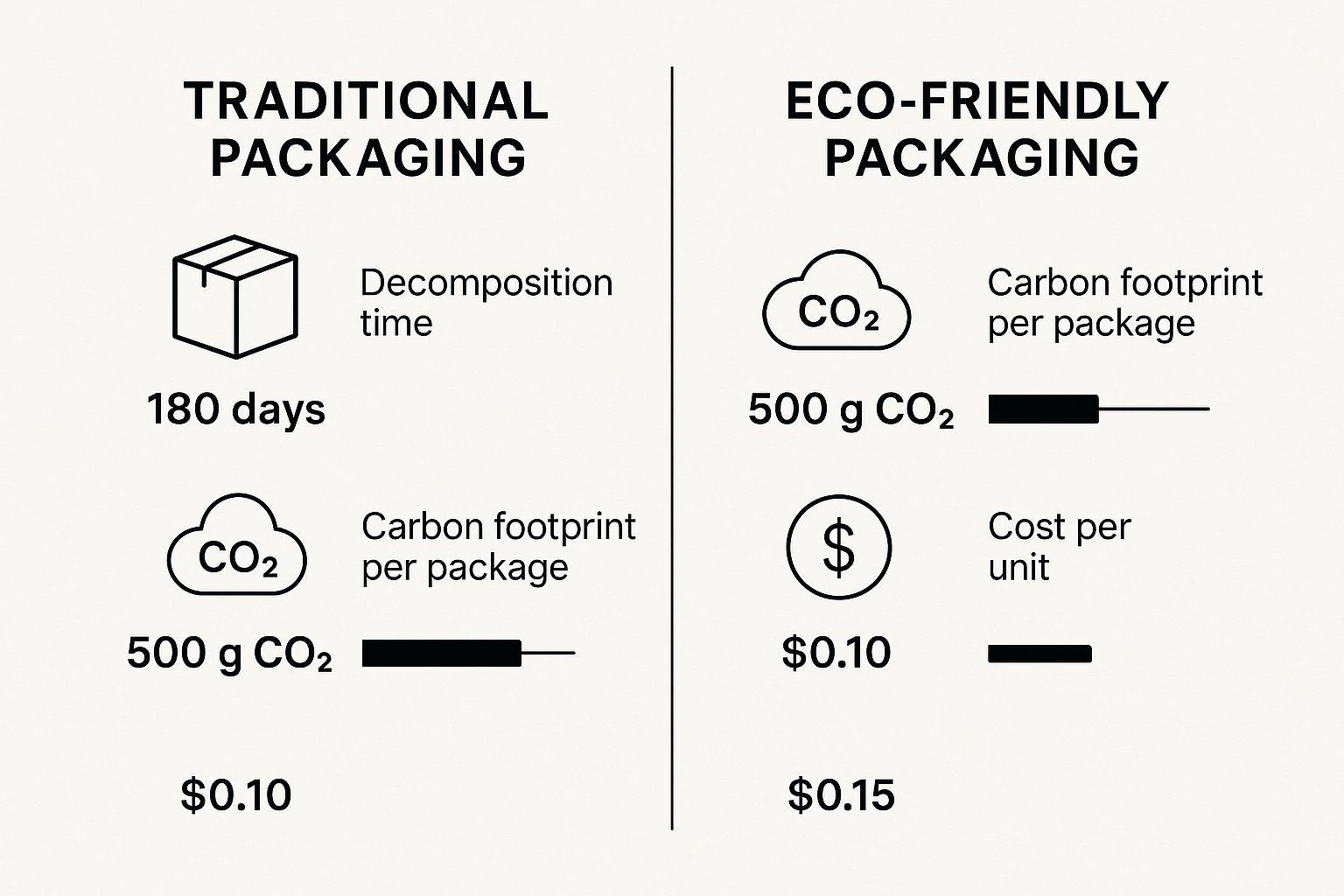

Consumers are increasingly eco-conscious, so consider plant-based and biodegradable options. These sustainable alternatives can be a major selling point. However, these eco-friendly materials can sometimes cost more.

To help you choose the best material for your needs, take a look at the comparison table below. It details the pros and cons of each option.

Cookie Box Materials Comparison

| Material Type | Durability | Cost Range | Eco-Friendliness | Best For |

|---|---|---|---|---|

| Kraft | Moderate | Low | High (Recyclable) | Simple cookies, rustic branding |

| Cardboard | High | Medium | Moderate (Recyclable) | Most cookies, printed designs |

| Corrugated Cardboard | Very High | Medium-High | Moderate (Recyclable) | Delicate cookies, long-distance shipping |

| Plant-Based/Biodegradable | Varies | High | High (Compostable/Biodegradable) | Eco-conscious brands, premium cookies |

As you can see, each material offers unique benefits. Choosing the right one depends on your specific priorities and budget.

Structural Integrity: Beyond the Hype

The structure of your cookie box is just as important as the material. Some structural elements are purely decorative, while others play a vital role in protecting your cookies during transit. Inserts, for example, can keep individual cookies separate and prevent breakage.

- Inserts: Offer added cushioning and keep cookies from shifting during shipping.

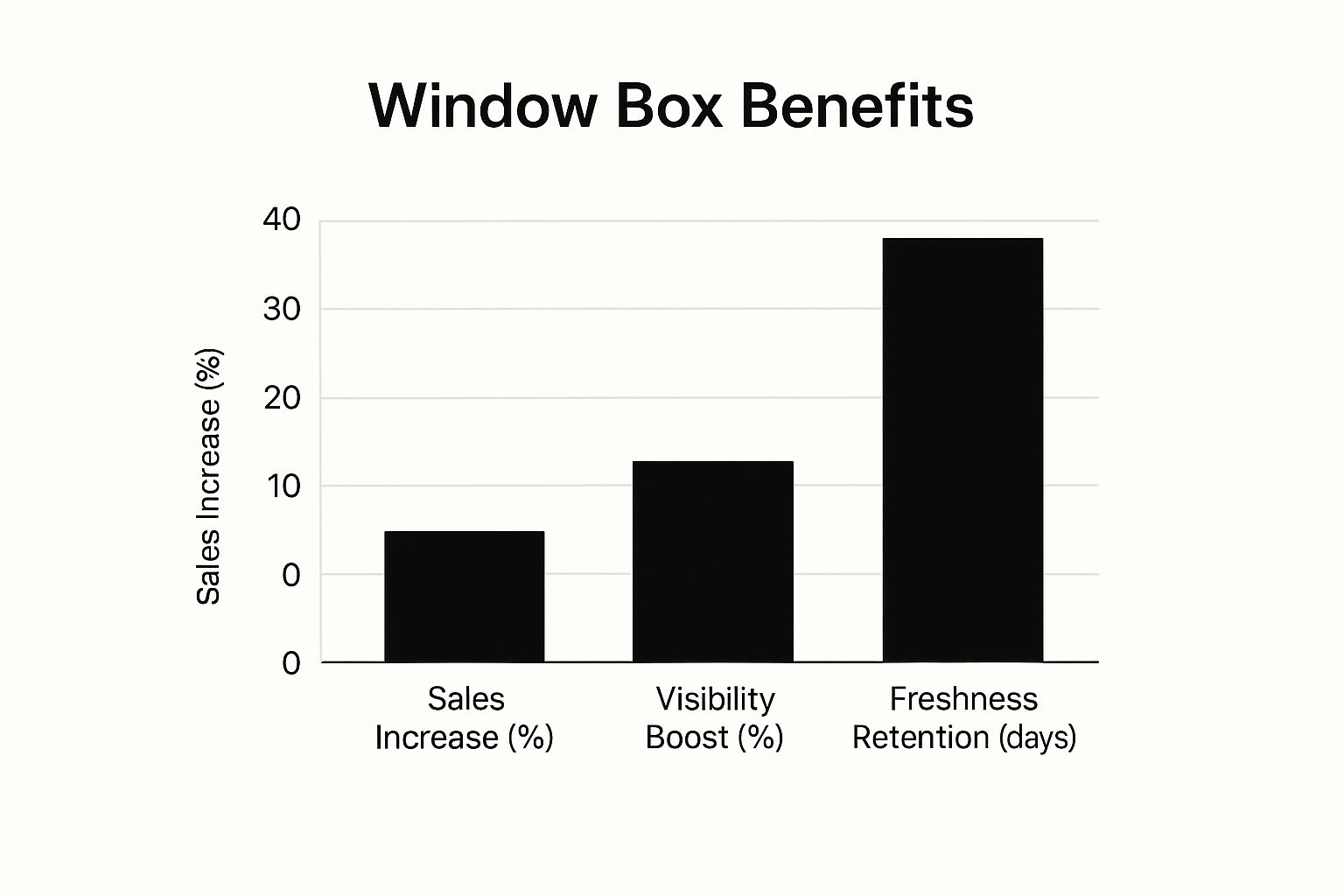

- Windowed Boxes: Let customers see the delicious treats inside without opening the box, encouraging impulse buys.

- Reinforced Corners: Help protect the box from damage and keep its shape during shipping.

These features not only protect your cookies but also enhance the customer experience. However, beware of features that prioritize style over substance. Packaging experts often warn against overly complicated designs that increase costs without providing adequate protection.

Creating a Memorable Unboxing Experience

When a customer opens your cookie box, you have a golden opportunity to make a lasting impression. Top bakeries are using creative closing mechanisms, custom inserts, and windowed boxes to elevate the unboxing experience. This can lead to more social media shares and stronger brand loyalty.

- Custom Inserts: Create a visually appealing presentation and showcase your cookies beautifully.

- Ribbons and Ties: Add a touch of elegance and make the unboxing feel more special.

- Branded Stickers or Seals: Reinforce your brand and create a personalized touch.

These small details can transform a simple purchase into a memorable event. This boosts repeat business and builds a strong connection with your customers. It’s particularly effective for building brand loyalty and generating positive word-of-mouth marketing.

Customization That Converts: Making Cookie Boxes Bulk Work

Customization is more than just slapping a logo on your bulk cookie boxes. It’s about transforming your packaging into a dynamic marketing tool that boosts sales. However, not all customization strategies are equally effective. Some are smart investments, while others can drain your resources without a worthwhile return. This section explores how to make customization work for your bakery.

Boosting Sales Through Strategic Personalization

Savvy bakeries have achieved remarkable results by personalizing their packaging. They’ve seen increases in average order values between 22-38%. This might involve designing limited-edition boxes for holidays or adding personalized messages for corporate gifts and events. This targeted approach makes customers feel special and appreciated, fostering loyalty and repeat business. Imagine a local bakery partnering with other businesses to create co-branded cookie boxes for promotional events. That’s the power of personalization.

Balancing Design and Production Realities

While ambitious designs are enticing, it’s crucial to balance creativity with practical production considerations. Digital printing offers high-quality, customized results without the high costs of traditional methods. Using flexible packaging materials expands your customization options and can even lower shipping costs. This allows you to achieve a premium look without breaking the bank.

The Psychology of Effective Packaging Design

Packaging design significantly influences customer behavior. Color psychology, for example, plays a crucial role in buying decisions. Warm colors like red and orange can stimulate appetite, while cool colors like blue and green convey freshness and health. Unique box shapes and interesting opening mechanisms enhance the unboxing experience and strengthen brand recognition.

Navigating the Customization Process with Manufacturers

Clear communication with your packaging manufacturer is essential to prevent costly mistakes and delays. Provide precise design specifications, including color codes (Pantone Matching System or PMS colors), material preferences, and dimensions, to minimize misunderstandings. Regular communication throughout production ensures your vision is brought to life accurately.

Market Growth and Customization Opportunities

The global cookie market is experiencing robust growth, creating exciting opportunities for businesses that use customized packaging. By 2025, the market is projected to reach $44,010.8 million, with a CAGR of around 5.3%. Other estimates place the 2025 market size at approximately $42.31 billion. This growing demand, fueled by desires for convenience and indulgence, underscores the importance of differentiating your brand with innovative and personalized packaging. Customizing your bulk cookie boxes is no longer a luxury; it’s a necessity for staying competitive and capturing the attention of today’s consumers.

Building Supplier Partnerships For Cookie Boxes Bulk Success

Finding the right supplier for your cookie boxes bulk orders is more than just getting the lowest price. It’s about building a reliable, long-term partnership. You need a supplier who understands your specific needs, consistently delivers high-quality products, and becomes a true asset to your business. We’ve talked to bakery owners and learned what separates the dependable packaging partners from the ones that create constant headaches.

Evaluating Potential Suppliers: Beyond The Surface

Don’t just compare price quotes. You need to dig deeper and understand each potential supplier’s true capabilities and limitations. Ask specific questions about their production capacity, lead times, and quality control processes. For example, ask about their experience with bulk orders and their ability to meet tight deadlines. This helps you determine if they can consistently provide the volume you need, when you need it. Also, request samples of their cookie boxes to check the quality of the materials and printing firsthand.

Building Mutually Beneficial Relationships

A strong supplier relationship is like any other valuable business connection: open communication and clear expectations are crucial. Regularly communicate your needs and provide feedback on their performance. This builds trust and helps them understand your business inside and out. This can often lead to perks, like priority order fulfillment during shortages or access to exclusive deals. Some bakeries have even negotiated better payment terms or faster shipping by nurturing strong supplier relationships, securing their cookie boxes bulk supply even during high demand.

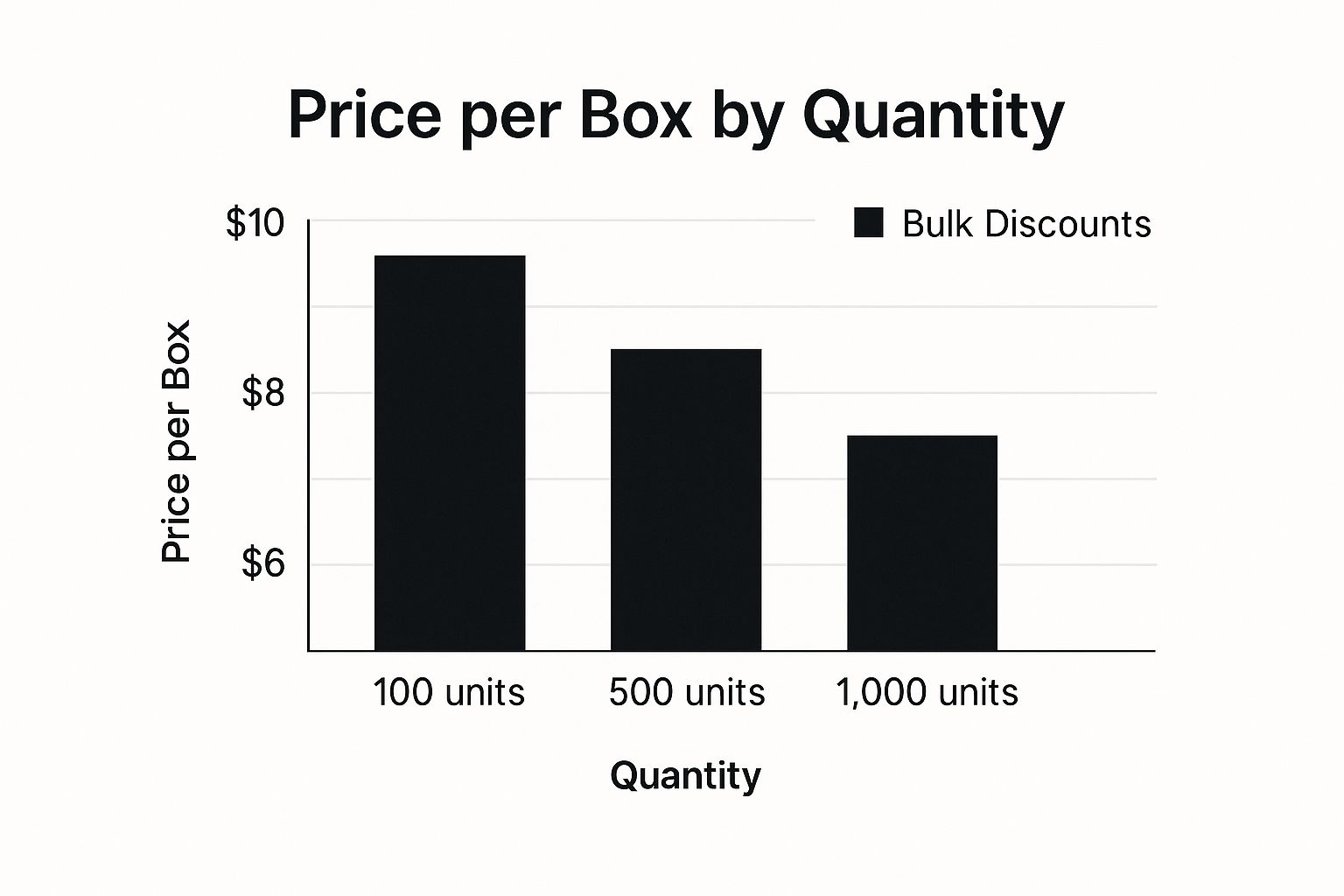

Negotiation Tactics For Bulk Packaging Orders

Negotiating bulk orders isn’t just about haggling over the price. Think about other factors like payment terms, shipping costs, and potential discounts for future orders. Some bakeries negotiate a lower per-unit price for a larger upfront order or a longer-term contract. Others have saved thousands of dollars by negotiating favorable terms on their cookie boxes bulk purchases without sacrificing quality.

Manufacturer Vs. Distributor: Choosing The Right Path

The choice between working directly with a manufacturer or a distributor depends on your business needs and order volume. Manufacturers often offer lower prices for large bulk orders but may have higher minimum order quantities (MOQs). Distributors can be a good option for smaller businesses with lower order volumes, offering more flexibility.

To help you decide, take a look at this comparison:

Cookie Box Supplier Comparison Matrix

| Supplier Type | Price Range | MOQ | Customization Options | Lead Time | Best For |

|---|---|---|---|---|---|

| Manufacturer | Lower | Higher | More Extensive | Longer | Large businesses, high volumes |

| Distributor | Higher | Lower | Less Extensive | Shorter | Small businesses, lower volumes |

Choosing the right supplier for your cookie boxes bulk needs is a strategic decision that can significantly impact your business. By carefully evaluating potential partners, building strong relationships, and negotiating effectively, you can ensure a steady supply of high-quality packaging to support your growth, letting you focus on what matters most: baking delicious cookies.

The Real Economics of Cookie Boxes Bulk Purchasing

Beyond the sticker price of each box, there’s a bigger financial picture to consider when buying cookie boxes in bulk. Savvy bakeries understand the interplay of cash flow, storage, and potential discounts. Thinking strategically about these elements can significantly impact profitability and ensure long-term success.

Optimizing Order Quantities for Maximum Savings

The most successful bakeries don’t just buy the most boxes they can; they determine their optimal order quantity. This means finding the right balance between getting the best possible price breaks and keeping storage costs and the risk of stale inventory low.

For example, a bakery might use past sales data to forecast demand and then consider its available storage space before making a large order. This approach minimizes the risk of having too much stock and keeps capital free.

Hidden Costs of Bulk Purchasing

Bulk buying can offer appealing per-unit savings, but hidden costs can eat into those gains. Bakeries must consider warehousing expenses, the possibility of inventory depreciation, and even the chance of damage or obsolescence.

This is why a strong overall inventory management plan is essential before committing to large orders. Careful planning and accurate forecasting are key to avoiding these financial traps.

Packaging Budget Allocation and Customer Experience

Attractive packaging creates a positive customer experience, leading to repeat customers and stronger brand loyalty. Balancing quality packaging with cost-effectiveness is essential for any bakery’s budget.

Finding budget-friendly ways to create an appealing presentation is crucial. A bakery might choose premium cookie boxes in bulk for special occasions and use more affordable options for everyday sales. This tiered approach creates a positive customer experience without breaking the bank.

Leveraging Seasonal Purchasing and Tax Advantages

Timing bulk purchases around seasonal demand fluctuations can unlock more savings. Many suppliers offer substantial discounts during slower periods. This is a great opportunity to stock up on cookie boxes in bulk for less.

Also, packaging can often be a tax-deductible business expense. Speaking with a tax advisor can help you understand how to best leverage these deductions and optimize your packaging budget.

Negotiating Beyond Price

Effective negotiation is key to making the most of cookie boxes bulk purchases. Bakeries shouldn’t just focus on the price per unit; they should also explore other favorable terms. Think extended payment options, free or reduced shipping costs, or even combined deals with other packaging materials.

This proactive approach builds better relationships with suppliers and gets you the best value for your money. These extras improve your bottom line and stretch your packaging budget further.

Sustainable Cookie Boxes Bulk: Beyond the Green Washing

Consumers are increasingly aware of the environmental impact of their purchases, and packaging plays a significant role in their decision-making. For bakeries, sustainable packaging is a crucial business strategy. It’s about moving beyond superficial “greenwashing” and truly embracing eco-friendly practices.

Navigating the Landscape of Eco-Friendly Materials

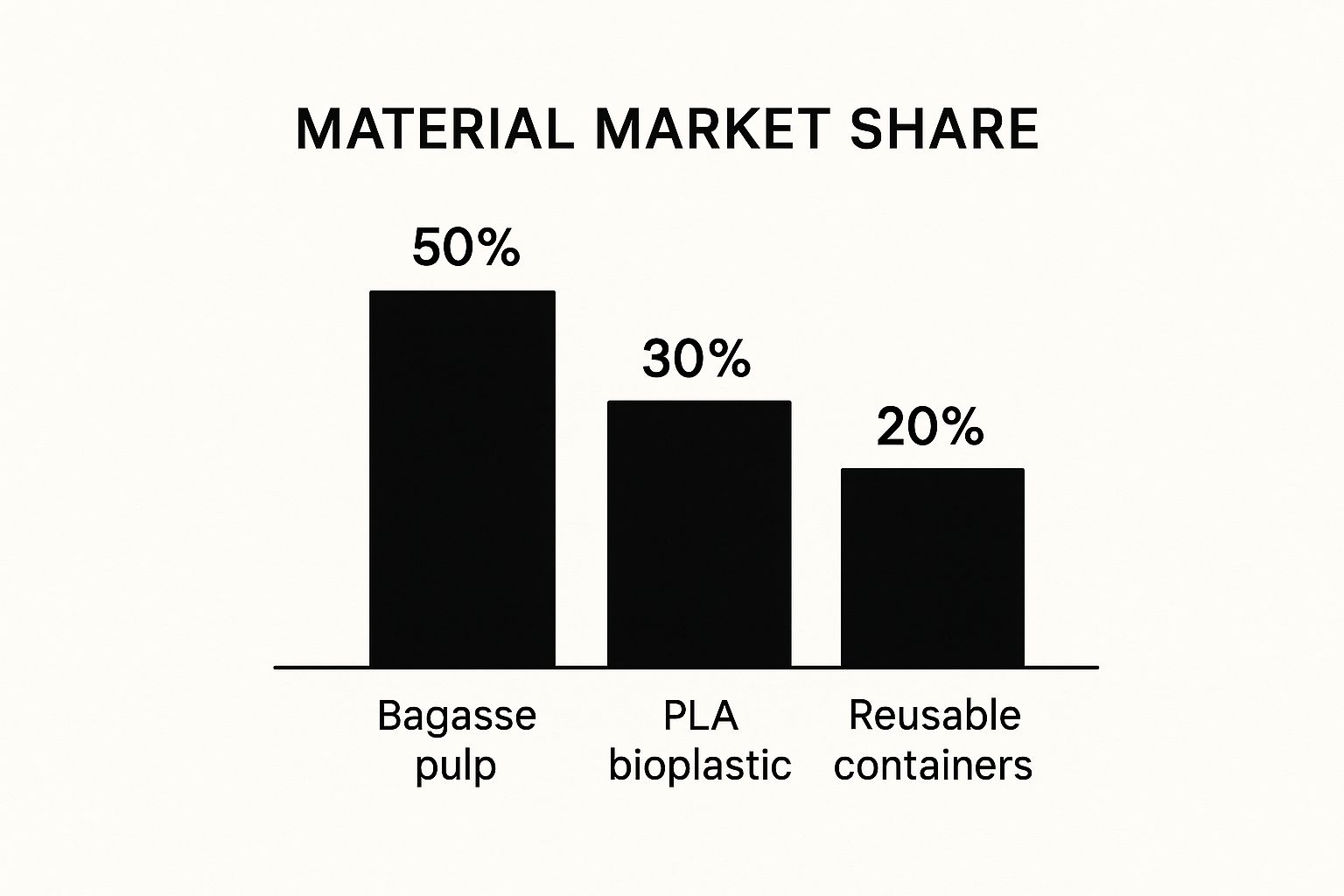

The market is flooded with “eco-friendly” packaging, but not all options are created equal. Compostable materials, made from plant-based sources like cornstarch or sugarcane bagasse, offer a compelling alternative to traditional cardboard. These materials break down naturally under specific conditions. Recycled cardboard, using pre-consumer or post-consumer waste, reduces the demand for virgin materials. However, the effectiveness of these materials depends on access to composting and recycling facilities.

- Compostable Boxes: Ideal for eco-conscious consumers, but require appropriate disposal.

- Recycled Cardboard: Reduces reliance on new materials and is widely recyclable.

- Kraft Paper: A natural, unbleached, and recyclable option with a rustic aesthetic.

Communicating Your Sustainability Efforts

Transparency is key to building trust with consumers. Clearly communicate the sustainable features of your bulk cookie box packaging. For example, emphasize the use of recycled content or the compostability of the materials. This open communication reinforces your brand’s commitment to sustainability and resonates with values-driven customers.

Consider using certifications and labels from reputable organizations. This third-party validation adds credibility and assures customers that your packaging meets recognized environmental standards.

Balancing Cost and Conscience: The ROI of Sustainable Packaging

Sustainable packaging often has a higher upfront cost than conventional options. However, this investment can offer significant long-term returns. Studies show consumers are willing to pay more for sustainably packaged goods. This increased customer loyalty and premium brand positioning can offset the initial cost difference and improve your bottom line.

Moreover, the demand for sustainable packaging is growing alongside the global snacks market. The global cookies market, including bulk sales, is influenced by consumer trends. By 2033, the cookies market is projected to grow from $42.31 billion in 2025 to about $65.95 billion, a CAGR of 5.70%. This growth highlights evolving consumer preferences towards sustainability.

Implementing a Phased Approach to Sustainable Packaging

Transitioning to fully sustainable packaging can be challenging, especially for businesses with tight margins. A phased approach allows bakeries to gradually incorporate eco-friendly practices. Start by switching to recycled cardboard for bulk orders, then explore compostable options for inner packaging. This gradual implementation minimizes disruption and allows businesses to adapt to the evolving landscape of sustainable packaging.

By understanding sustainable materials, communicating your efforts transparently, and implementing a strategic approach, you can transform your packaging from a potential environmental liability into a valuable brand asset.

Mastering Cookie Boxes Bulk Inventory Management

Managing a large inventory of cookie boxes can be a real challenge. But with the right strategies, you can transform your packaging stockpile from chaotic to completely controlled. This is especially important when dealing with cookie boxes bulk orders, impacting both your profits and customer satisfaction. Let’s explore some proven methods used by successful bakeries.

Space-Efficient Storage Solutions

Effective storage is key for maintaining the quality of your cookie boxes bulk purchases and maximizing your space. Vertical storage solutions, like sturdy shelving units, are a great way to optimize limited space. This not only keeps boxes organized but also prevents damage. Some bakeries even use specialized racks designed for different box sizes, minimizing wasted space and simplifying access.

Scalable Inventory Tracking Methods

As your business expands, your inventory tracking must keep pace. Start with simple tools like spreadsheets to track your cookie boxes bulk stock. As your needs grow, consider dedicated inventory management software. These digital tools offer real-time insights into stock levels, preventing costly stockouts and overordering. This helps ensure you have the right amount of boxes without tying up too much capital.

Strategic Seasonal Packaging Management

Seasonal packaging can definitely boost sales, but it also presents unique inventory hurdles. Balancing bulk discounts with cash flow management is essential. Stocking up on holiday-themed boxes months in advance can save money. However, accurate demand prediction is crucial to avoid excess stock post-season. Analyze past sales and current market trends for informed decisions.

Predicting Packaging Needs and Buffer Stock

Predicting packaging needs is vital for managing cookie boxes bulk inventory efficiently. Use sales forecasts to estimate your requirements and include a buffer stock for unexpected delays or spikes in demand. This buffer acts as a safety net, preventing production delays due to supplier issues or sudden order increases. For instance, if your supplier’s lead time is two weeks and you anticipate a 10% increase in orders, adjust your buffer accordingly.

Creative Solutions for Space-Constrained Environments

Limited storage is a common challenge for bakeries. Creative thinking can help you overcome this. Rolling carts allow easy movement of cookie boxes bulk inventory around the production area. Off-site storage is another option for less frequently used packaging, freeing up valuable space in your facility. These strategies maximize space and boost efficiency.

Ready to improve your bakery’s packaging and streamline operations? Explore the wide selection of high-quality cookie boxes and other packaging solutions at MrTakeOutBags.com. We can help you find the perfect fit for your needs and budget.