Navigating The Wholesale Takeout Container Market Like A Pro

Let’s talk wholesale takeout containers. When I first opened my doors, I was all about the cheapest price. Mistake. I learned the hard way that flimsy containers that melt in the microwave aren’t exactly a recipe for happy customers. There’s more to this than meets the eye – it’s not just about the initial cost.

Quality matters. Storage matters. A reliable supplier? Essential. Trust me on this. These factors can make or break your bottom line in the long haul. When you’re searching for the right wholesale containers, online platforms are your friend. They can open up a whole world of possibilities.

Also, remember this market is constantly changing. New suppliers are always popping up, and sustainability is a huge deal now. Forget those old styrofoam clamshells – we’re talking biodegradable, compostable, even reusable container programs.

This shift in what customers want has really shaken things up. The wholesale takeout container market has exploded! In 2024, it was worth about $109.1 billion, and it’s expected to hit $163 billion by 2034. That’s a massive jump.

This growth shows just how much demand there is for eco-friendly and convenient packaging. Knowing the current market trends is key to making informed buying choices. Don’t just grab the cheapest option. Think long term. Factor in things like storage fees, having to replace cheap containers that break, and the headache of unreliable suppliers.

I’ve personally seen restaurants cut their annual container costs by 40% or more just by understanding these things. By considering all these factors up front, you won’t just save money, you’ll also be doing your part for a more sustainable takeout system. And that’s something we can all feel good about.

Matching Container Types To Your Real Business Needs

Picking the right takeout containers for your business isn’t about grabbing the cheapest ones on the shelf. I’ve seen firsthand how that strategy can backfire – soggy salads, squished desserts, and customers who aren’t too thrilled. Your containers should protect and present your food, not become part of the problem. Think of it like this: different materials bring different strengths to the table.

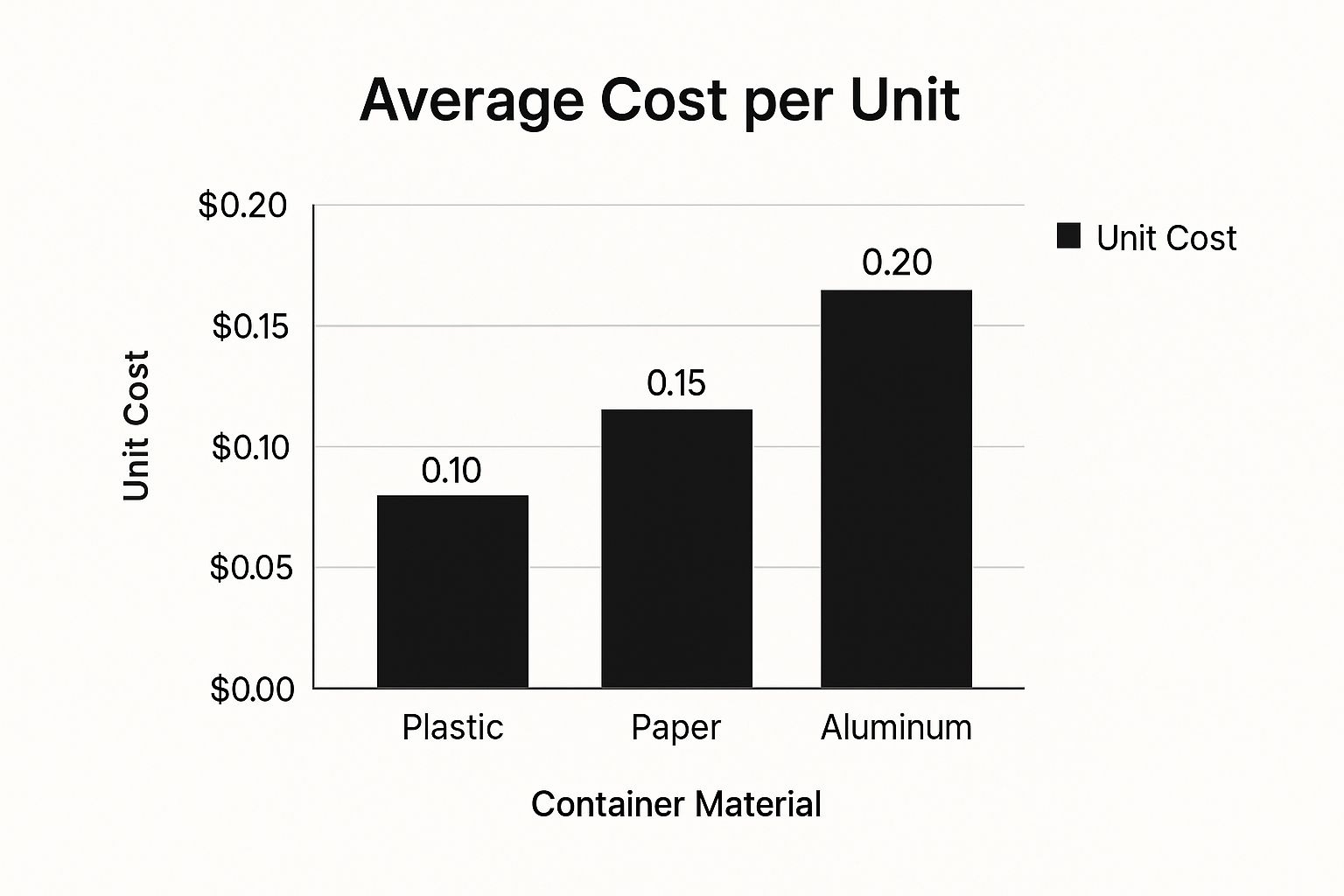

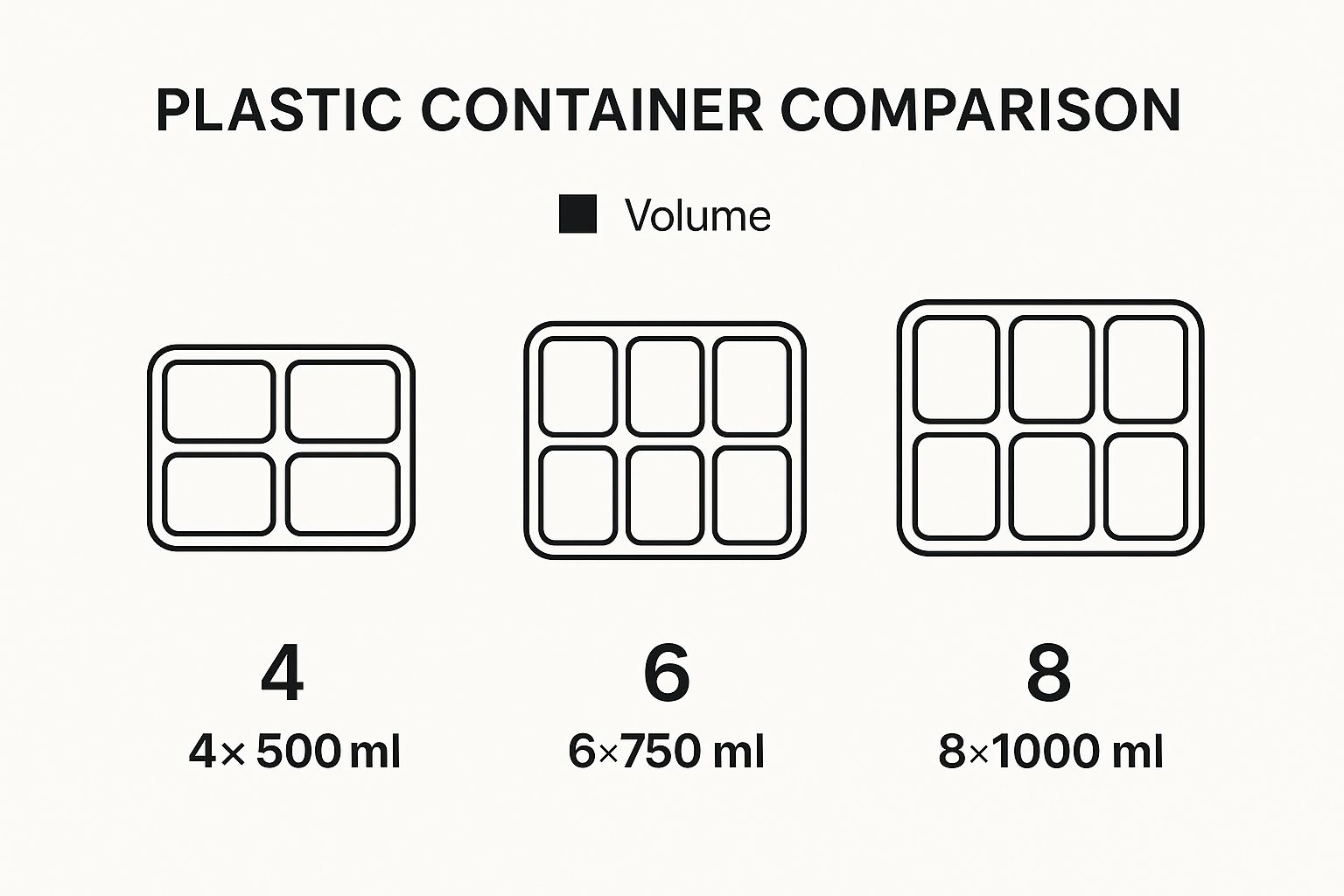

The infographic above gives you a quick visual on cost differences between the usual suspects: plastic, paper, and aluminum. Plastic tends to be the most budget-friendly, followed by paper, then aluminum. But, as we all know, cost isn’t the only factor.

Choosing The Right Material For The Job

Imagine you’re serving up steaming hot soup or a saucy pasta dish. You’ll need a container that can handle it without leaks or spills. While cheap, plastic might not be the best choice for hot, greasy foods. Paper, though generally a more eco-friendly choice, can get soggy quickly. Aluminum, while the priciest, is fantastic at holding in heat and keeping food at its best.

Even something as simple as kitchen degreasing can be affected by your container choice. Think about the residue different foods leave behind.

Your containers also speak volumes about your brand. Eco-friendly options show you’re thinking about sustainability, while sturdy, high-quality packaging tells customers you value their experience. What message do you want to send?

Switching Container Types Smoothly

Changing container types doesn’t have to be a disruptive process. The key is careful inventory management during the transition. Keep your staff informed about the changes, and the switch will be seamless, keeping your operations running efficiently and your customers happy.

To help you visualize the differences between materials, I’ve put together a quick guide based on my own experience:

Container Material Performance Guide

| Material Type | Cost Range | Durability Rating | Eco-Friendliness | Best Applications | Customer Response |

|---|---|---|---|---|---|

| Plastic | Low | Moderate | Low | Cold foods, dry items | Mixed – concerns about environmental impact |

| Paper | Medium | Low to Moderate | Moderate to High (depending on sourcing) | Sandwiches, pastries, dry items | Generally positive, especially if sustainably sourced |

| Aluminum | High | High | High (recyclable) | Hot foods, soups, oily dishes | Positive – perceived as high-quality |

This table summarizes the pros and cons of each material, highlighting their best applications and typical customer reactions. As you can see, there’s no one-size-fits-all answer. The “best” choice depends on your specific needs and priorities.

Finding Suppliers Who Actually Deliver What They Promise

Finding a good wholesale takeout container supplier can be a real headache. I’ve spoken with so many restaurant owners who’ve been let down by suppliers who make big promises they just can’t keep. Trust me, it’s not just about the cheapest price. It’s about a reliable partner, someone you can count on when the kitchen’s in full swing.

One major warning sign is pricing that seems too good to be true. If a deal seems unbelievably low, investigate further. Ask about their production capabilities and what their backup plan is if things go wrong. A supplier who can’t handle a busy Friday night rush is going to leave you hanging.

Communication is another key factor. A reliable supplier will proactively update you on your order’s status and any possible delays. They’ll also answer your questions quickly. I learned this the hard way once with a supplier who vanished for a whole week during a holiday rush. Never again! Consistent communication is essential.

Balancing Local and National Options

Think about the supplier’s location, too. Regional suppliers often provide more personalized service and quicker deliveries. However, their stock might be more limited than a national supplier. National suppliers offer more consistent availability but might not be as flexible with custom orders or urgent requests.

The takeout container industry itself is growing rapidly. The market, valued at USD 113,351.7 million in 2025, is projected to hit USD 159,893.7 million by 2035. This growth shows just how much demand there is for these products. Finding a supplier who can meet this demand is vital for your business.

Building a good relationship with a supplier requires time and effort. Don’t hesitate to ask the tough questions, negotiate terms, and seek out partners who value your business. A dependable supplier can be the difference between smooth sailing and a logistical nightmare. Finding the right wholesale takeout container supplier is an investment worth making.

Getting Your Numbers Right The First Time

Ordering the right number of wholesale takeout containers is a real balancing act. Order too many, and you’re stuck with boxes piling up and cash tied up in inventory. Too few, and you’re scrambling to find more at the last minute, potentially losing sales. Most businesses get tripped up initially by focusing just on the unit price, but there’s a smarter way to go about it.

Let’s ditch the complicated spreadsheets and get down to some practical tips I’ve learned over the years.

Forecasting Demand and Avoiding Excess Inventory

First things first: track your current usage. Look at your sales data from the past few months. Are there any patterns? Maybe you sell more salads in the summer and soups in the winter? This will tell you which types of containers you need more of at different times of year.

Also, think about any upcoming menu changes or expected growth. Launching a new takeout item? You’ll definitely need to factor that into your container orders.

The Balancing Act: Volume Discounts vs. Cash Flow

We all love a good discount. Larger orders often come with enticing price breaks, but tying up too much cash in inventory can really hurt your cash flow. Think outside the box (pun intended!) when it comes to storage. Could you negotiate a staggered delivery schedule with your supplier? Maybe even explore shared storage options with other businesses in your area? Getting creative with storage can free up cash and space.

Learning From Costly Mistakes

I once talked to a restaurant owner who learned this lesson the hard way. They overestimated demand for a new menu item and ended up with mountains of unused containers taking up valuable storage space. Ouch.

They wisely adjusted their strategy by ordering smaller quantities at first, and then increasing their orders as the demand grew. It’s a great example of why starting small and scaling up is often better than getting stuck with extra inventory.

To help you visualize the impact of different order quantities, I’ve put together this handy table:

Volume Purchasing Impact Calculator

| Order Quantity | Unit Price | Total Investment | Savings Percentage | Storage Requirements | Cash Flow Impact |

|---|---|---|---|---|---|

| 1000 | $0.50 | $500 | 0% | 10 sq ft | -$500 |

| 5000 | $0.45 | $2250 | 10% | 45 sq ft | -$2250 |

| 10000 | $0.40 | $4000 | 20% | 90 sq ft | -$4000 |

| 20000 | $0.35 | $7000 | 30% | 180 sq ft | -$7000 |

As you can see, while larger orders offer greater savings per unit, the total investment and storage requirements increase significantly. Finding that sweet spot where you’re maximizing your savings without negatively impacting your cash flow is key.

By looking at the data and considering all these factors, you can make smart decisions about your takeout container needs, saving money and making your operations more efficient.

Ensuring Quality Without Getting Lost In The Details

Finding the right suppliers and figuring out how many containers you need is essential, but let’s be honest, quality matters just as much. We’re not just talking about containers surviving the delivery trip; it’s about food safety, regulations, and your brand’s reputation. Nobody wants soggy food or a leaky container ruining their meal.

Understanding The Essentials

Navigating FDA approvals and local health department rules can feel like wading through a swamp. I remember when I first started; I was completely lost. But truthfully, grasping the basics isn’t rocket science, and it’s crucial for avoiding legal headaches and, more importantly, keeping your customers safe. As you explore quality, you might also want to think about more eco-friendly takeout container options.

The takeout container market is booming, currently sitting at a whopping USD 172.19 billion globally. It’s expected to skyrocket to USD 228.12 billion by 2030. This insane growth really highlights how important it is to make smart choices in this area.

Testing and Asking The Right Questions

Before you order a mountain of wholesale takeout containers, test them out! I always get samples and really put them through the wringer. Fill them with hot food, cold food, I even freeze them overnight just to see what happens. It’s such a simple step that can prevent a costly mistake down the line.

Don’t be afraid to grill your supplier about their quality control process, either. What certifications do they have? What steps do they take to make sure their containers meet all the safety standards? A reputable supplier will be upfront and happy to answer your questions. This tells you they’re invested in providing good quality, just like you are.

Real-World Consequences of Substandard Containers

I’ve heard some nightmare stories about restaurants using cheap containers that leaked or warped, leading to unhappy customers and even legal battles. It’s simply not worth the risk. While investing in high-quality containers might cost a little more upfront, it’s a small price to pay for your peace of mind and a loyal customer base. Trust me, doing it right the first time will save you money and a lot of stress in the long run.

Smart Buying Tactics That Actually Work

Let’s dive into the nitty-gritty of buying wholesale takeout containers without emptying your wallet. One of the biggest secrets? Timing. Think of it like grocery shopping – you wouldn’t buy steaks when they’re not on sale, right? Wholesale prices shift too, influenced by seasons, holidays, and even big events. Keeping an eye on these patterns can give you a serious leg up.

Negotiation: Building Relationships, Not Just Haggling

Negotiating with suppliers isn’t about being a hard-nosed bargainer. It’s about building genuine relationships. In my experience, honesty and rapport go a long way. Instead of demanding a lower price, try explaining your situation. Are you a new business just starting? Are you trying to switch to more sustainable containers, but the cost is a hurdle? Suppliers are often willing to work with you if they see your commitment.

Thinking Outside The (Takeout) Box

Creativity is key. Consider teaming up with other local businesses to buy in bulk. I’ve seen restaurants join forces to buy wholesale takeout containers together, significantly reducing their individual costs. Another option? Supply partnerships. These long-term contracts, with a guaranteed purchase volume, can open doors to better pricing and more reliable service.

Payment Terms and Minimum Orders

Don’t overlook the fine print. Some suppliers offer discounts for early payment, while others have stricter terms. Minimum order requirements are also important. You want to snag those bulk discounts, of course, but balance that with your storage space and cash flow. Don’t overspend just to get a slightly lower unit price.

Emerging Trends: Staying Ahead of the Curve

The wholesale world is constantly evolving. Subscription-based ordering is gaining popularity, offering automated deliveries and potential savings. Technology is also reshaping how businesses order and manage inventory. Staying informed about these trends can be a game-changer. By combining these smart buying tactics with a solid understanding of the market, you can drastically reduce your packaging costs and build stronger relationships with your suppliers.

Making Your Move With Complete Confidence

So, you’re thinking about switching to wholesale takeout containers? Great! Let’s chat about making that happen without any major hiccups. I’ve helped lots of businesses navigate this transition, and trust me, it doesn’t have to be a stressful ordeal.

One of the biggest roadblocks I see is that initial hesitation. It’s easy to get caught up in “what ifs.” Will the new containers be sturdy enough? Will my supplier be reliable? These are totally legitimate concerns, and we’ll address them.

Setting Up For Success: Monitoring and Optimizing

Think of your container strategy like an ongoing experiment. You’re not just buying containers; you’re building a whole system. Set up a simple way to track how your supplier is doing. Are deliveries on time and complete? Are the containers arriving in good condition? These little things add up.

Inventory management is key, too. Keep an eye on your stock, but don’t get tempted to over-order just for a bigger discount. Cash tied up in inventory isn’t doing you any good. Regularly review your purchasing data. Ask yourself: Am I ordering the right kinds of containers at the right times? Tweak your strategy as you go, based on what’s actually working.

This screenshot is from the FDA’s website on food contact substances. It shows how seriously they take regulation and safety. Choosing FDA-compliant containers is crucial for protecting your customers.

Learning From The Trenches: Real-World Experiences

Talking to other business owners who’ve already made the switch to wholesale is invaluable. I’ve picked up so many helpful tips and tricks this way – and heard some cautionary tales, too! One surprising thing I learned was how many businesses discovered unexpected benefits after switching. Not just cost savings, but things like increased efficiency and even happier customers due to higher-quality containers.

Building on those initial wins comes down to continuous improvement. As your business grows and changes, so will your container needs. Be ready to adapt. Maybe your menu expands, and you need different sizes or materials. Flexibility is your friend.

Ready to explore wholesale takeout containers? MrTakeOutBags.com has a huge selection of high-quality, eco-friendly options. Their team has been helping businesses like yours since 2005, so they really know their stuff. They can help you find the perfect fit.